English

English

10

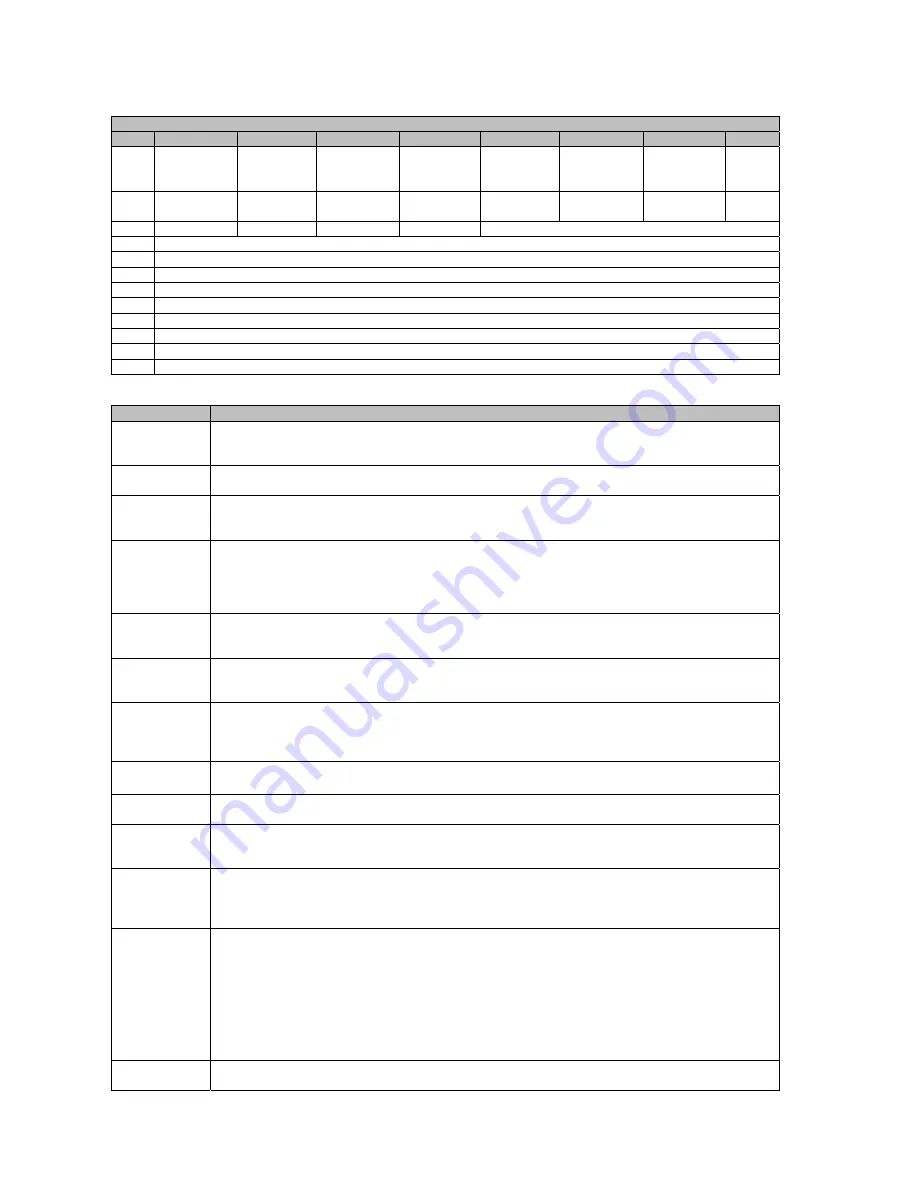

I/O Format

I/O from Welder to Master

Cyclic I/O From Welder to Master

Byte B7

B6

B5

B4

B3

B2

B1

B0

0 Misc

Module

Fault

Wire Stick

WC Fault

Water

Fault

WD Fault

Gas Fault

Touch

Sense

Arc

Detect

1

Anybus

Fault

PM Limit

PM Fault

Weld

Complete

Limit Error

2

Weld Sequencer Current State

3

4

Voltage Feedback, Low Byte (In Volts with 1 implied decimal places)

5

Voltage Feedback, High Byte

6

Current Feedback, Low Byte (In Amps with 1 implied decimal places)

7

Current Feedback, High Byte

8

Wire Drive Motor Current, Low Byte (Signed value In Amps with 2 implied decimal places)

9

Wire Drive Motor Current, High Byte

10

Wire Feed Speed Feedback, Low Byte

11

Wire Feed Speed Feedback, High Byte

I/O Bit Description to Master

Item

Description

Arc Detect

A True value indicates sufficient arc voltage and arc current have been detected. Arc voltage and

arc current levels are addicted to mode. When there is no longer sufficient Arc current and Arc

voltage then go to False.

Touch Sensed A True value indicates that the Touch Sense detected a short between the work piece and the

electrode.

Gas Fault

A True value indicates there is a failure in the gas controller. If a fault occurs the weld Power Wave

will turn the output off and welding will not be possible until the problem is corrected and the fault

is cleared.

WD Fault

Asserted when there is a fault in the Wire Drive. This fault occurs also when Shutdown input is

open on the external I/O connector Ref. Power Wave / Power Feed Wire Feeder Interconnections

section describing External I/O Connector in the Operator’s Manual. If a fault occurs the weld

Power Wave will turn the output off and welding will not be possible until the problem is corrected

and the fault is cleared.

Water Fault

True when Arclink Water Cooler reports an error. If a fault occurs the weld Power Wave will turn

the output off and welding will not be possible until the problem is corrected and the fault is

cleared.

WC Fault

True when there is a Weld Controller fault. Refer to “Troubleshooting” in the Operator’s Manual

for a list of possible errors. If a fault occurs the weld Power Wave will turn the output off and

welding will not be possible until the problem is corrected and the fault is cleared.

Wire Stick

True value indicates that after the welding output is turned off there is a short between the

electrode and the workpiece. This will stay true until the welding output is turned on and the error

is cleared or if a Touch Sense Command is asserted and the short has been cleared. This check

is disabled by default and be enabled using the option “Enable Wire Stick Check”.

Misc Module

Fault

True value indicates that a module, like the Advance Module, STT Switch, High Frequency Switch

has a fault.

Limit Error

Indicates that one of the Welding Job Parameters is out of limits. This will not stop welding

process.

Weld

Complete

Indicates that the weld has completed (subsequent to the trigger going false) including any

downslope, crater, burnback and postflow times. Goes false when the next weld begins (trigger

going true).

PM Fault

This bit is used to indicate that the Production Monitoring object is faulty, a common cause is that

the Production Monitoring object detected a limit error while welding and the Out of limit action

was set to Alarm Latch. This faulty condition must be cleared before welding; toggling the PM Flt

Reset bit to the welder should clear this condition.

PM Limit

This bit is used to indicate that the Production Monitoring (PM) object detected a limit error. This

bit is clear automatically when the trigger input goes on or when the PM Flt Reset bit to the welder

goes on.

This bit is basically just a status item indicating a PM limit fault occurred, but depending on how

PM is configured, other behavior can occur when this bit goes on. If PM is set to Fault System,

then PM will shut the Power Source output off automatically when a limit error occurs, this will

cause the LGA sequencer to fault and stop welding. If PM is set to Alarm Latch and a limit error

occurs, then the PM object will fault after the weld is over and welding can not resume until the PM

fault is cleared (see the PM Fault bit).

Anybus Fault

This bit is used to indicate that the Anybus module has a fault. This includes selecting a job with

invalid Workpoint or Trim units, or selecting an invalid Job number.