A-2

INSTALLATION

FLEXTEC

®

650x

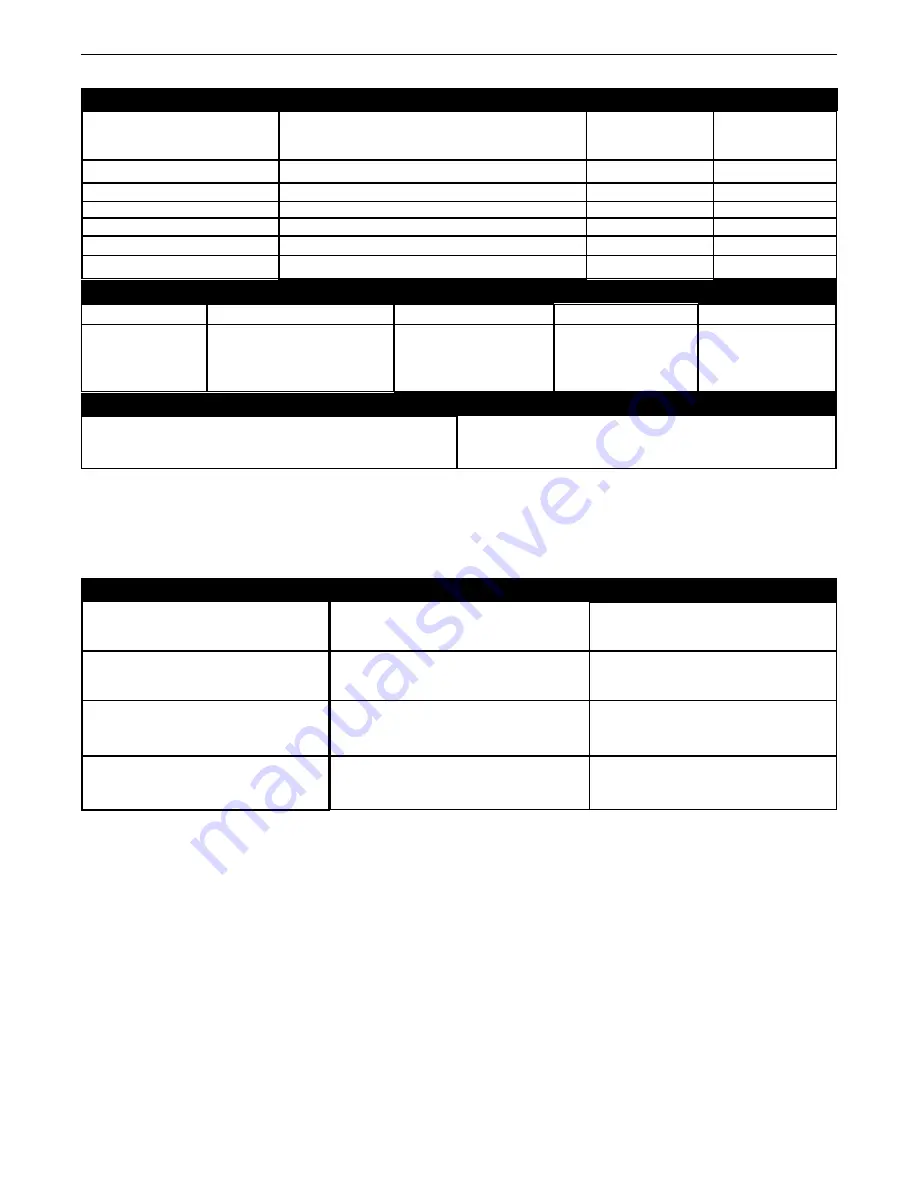

PHYSICAL DIMENSIONS

TEMPERATURE RANGES

HEIGHT

21.8 in (554 mm)

MODEL

K3425-1

WIDTH

16.14 in (410 mm)

DEPTH

29.33 in (745 mm)

WEIGHT

165lbs (74.8kg)

*

OPERATING TEMPERATURE RANGE

Environmentally Hardened: 14°F to 131°F (-10°C to 55°C

**

)

STORAGE TEMPERATURE RANGE

Environmentally Hardened: -40°F to 185°F (-40°C to 85°C)

PROCESS

GMAW (CV)

GTAW (CC)

SMAW (CC)

FCAW-G (CV)

FCAW-S (CV)

SAW (CV)

OUTPUT RANGE (AMPERES)

40-815

10-815

15-815

40-815

40-815

40-815

OCV (U

o

)

60

24

60

60

60

60

OCV (U

r

)

---

15

15

---

---

---

WELDING PROCESS

IP23 180º(H) Insulation Class

*

Weight does not include input cord.

**

Power Source is de-rated at temperatures above 40C.

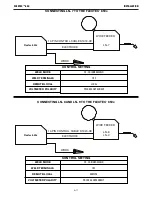

"A" LEAD

POSITION

380 Volt

Reconnect

460 Volt

Reconnect

575 Volt

Reconnect

VRD

Enabled

Low Limit - 340 Vac

High Limit - 420 Vac

Low Limit - 390 Vac

High Limit - 505 Vac

Low Limit - 485 Vac

High Limit - 620 Vac

VRD

Disabled

Low Limit - 340 Vac

High Limit - 455 Vac

Low Limit - 390 Vac

High Limit - 520 Vac

Low Limit - 485 Vac

High Limit - 655 Vac

AUXILIARY RECONNECT INPUT RANGES

Содержание Flextec 650x

Страница 37: ...F 2 DIAGRAMS FLEXTEC 650x L16096 2 A 01 15 97 15 09 26 85 29 31 21 16 21 83 23 66...

Страница 38: ...Flextec 650x 12596...

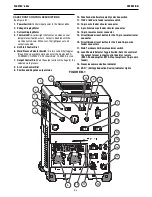

Страница 43: ...P 1101 C jpg Case Front Assembly Flextec 650x 12596 5 Printed 01 03 2017 at 13 39 33 Produced by Enigma...

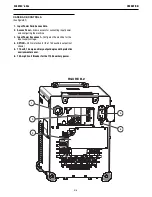

Страница 46: ...P 1101 D jpg Divider Panel Assembly 8 Flextec 650x 12596 Printed 01 03 2017 at 13 39 33 Produced by Enigma...

Страница 49: ...P 1101 E jpg Base Assembly Flextec 650x 12596 11 Printed 01 03 2017 at 13 39 33 Produced by Enigma...

Страница 51: ...P 1101 F jpg Case Back Assembly Flextec 650x 12596 13 Printed 01 03 2017 at 13 39 33 Produced by Enigma...

Страница 53: ...P 1101 G jpg Covers Assembly Flextec 650x 12596 15 Printed 01 03 2017 at 13 39 33 Produced by Enigma...