BK8053-000107 Rev A.01

FineLine 300HD Plasma System

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

Page 39 of 118

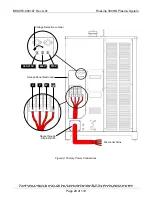

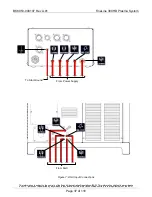

3.10 Torch Connections

Refer to Figure 9 for the physical location of all connections. When making brass fitting

connections, use two opposing wrenches and only tighten enough to make water or gas

seals. The fittings are subject to damage if over tightened.

Torch Leads and Torch Handle

1) Slide the torch lead isolator (and braided

shield) away from the torch end of the

torch leads by at least the length of the

torch handle.

Slide the torch leads through the non-

threaded end of the torch handle (the end

with two set-screw holes). Make sure that

all fittings are visible so that connections

can be made.

Electrode/Coolant Supply Lead

2) Connect the electrode/coolant supply

lead to the corresponding fitting on

the torch.

Plasma Gas Hose

3) Connect the plasma gas hose to the

corresponding fitting on the torch.

Nozzle Lead

4) Connect the nozzle lead to the

corresponding fitting on the torch.

Shield Gas Hose

5) Connect the shield gas hose to the

corresponding fitting on the torch.

Coolant Return Lead

6) Connect the coolant return lead to the

corresponding fitting on the torch. The

torch coolant return lead fitting has left

hand threads.

Torch CTP Sensor Lead

7) Connect the torch CTP sensor lead to the

corresponding connector on the torch.

Torch Leads

(Torch End)

Coolant

Return Lead

Nozzle Lead

Shield

Hose

Electrode/Coolant

Supply Lead

Torch CTP

Sensor Lead

Torch Handle

Torch Lead

Isolator

Set Screw

Hole

Plasma Hose

Coolant

Return Fitting

Plasma

Fitting

Shield

Fitting

Torch CTP

Sensor Connector

Nozzle

Fitting

Electrode/Coolant

Supply Fitting

Torch

(End View)

Figure 9: Torch Connections