B-4

INSTALLATION

APEX

®

30S

Cable Installation

The system is shipped out with cables connected,

how ever the components can be ordered separately

and installed by the end user, or the cables and com-

ponents may be removed during routine maintenance.

For the complete system cable map – see

FIGURES 8

and 9 - System Assembly.

Note:

• Always use the shortest cable lengths possible.

DO NOT coil excess cable. It is recommended that

the total length of control cable does not exceed

100’ (30.5M). The use of non-standard cables in

excess of 25’ (7.5M) can lead to communication

problems (system shut downs), poor motor accelera-

tion (poor arc starting), and low wire driving force

(wire feeding problems).

• Best results will be obtained when the control cables

are routed separate from the weld cables. This mini-

mizes the possibility of interference between the

high currents flowing through the weld cables and

the low level signals in the control cables.:

ArcLink cables can be used to extend the pendant

cable length.

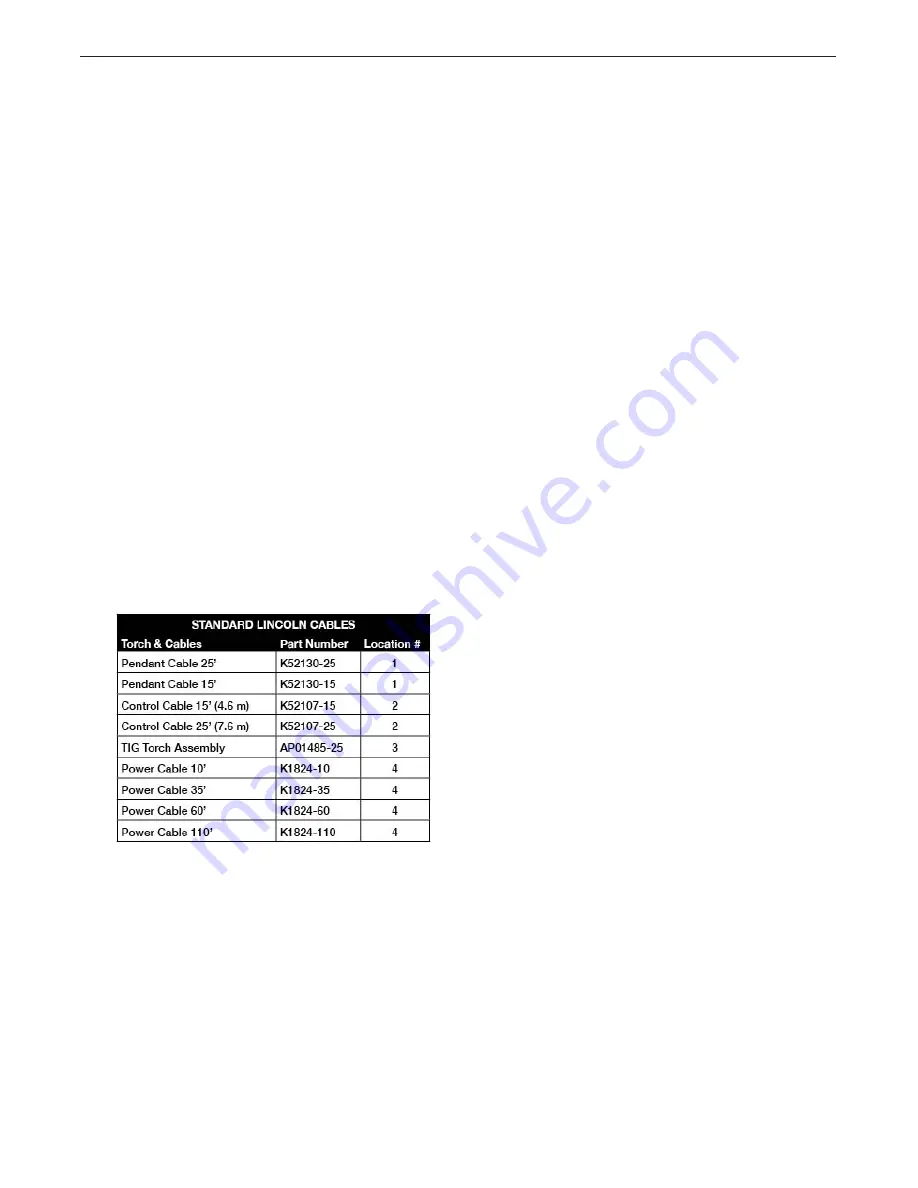

Cable List

1. Pendant Cable -

Connects from the pendant to

the control unit

2. Control Cable -

Connects from the weld head to

the control unit

3. Torch Assembly -

Runs from the control unit

out to the weld head. Includes power, sense lead,

gas and water lines

4. Work Cable* -

Connects from the POWER WAVE

unit (or Advanced Process Module if installed) to

the work piece

5. 3-Phase Power Cable* -

Connects power supply

to facility power (refer to power supply manual for

installation)

6. Gas Hose* -

Supplies gas to the system from

external source

7. Ethernet Cable* -

Optional cable to connect the

power supply to a local area network for added

system functionality

* Indicates items not included with the system