LIGHT PROGRESS

STICK-ST [eng]

feb-2019

Pag. 11/16

DECLARATION OF COMPLIANCE

We, LIGHT PROGRESS s.r.l., hereby declare under our own responsibility that the following units of own production:

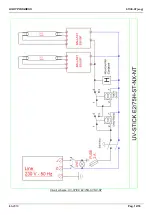

UV-STICK E2/75H-ST-NX-NT

series

are in accordance with EEC directive 2014/30/EU (Electromagnetic Compatibility)

are in accordance with EEC Machinery Directive dispositions 2006/42/EU

are in accordance with EEC Low Voltage Directive 2014/35/EU

are in accordance with EEC (RoHS) 2011/65/EU (D.Lgs 4 Marzo 2014, n.27)

TECHNICAL STANDARDS APPLIED

UNI EN ISO 12100:2010

Safety of Machinery - Basic Concepts, General Principles for Design - Risk

assessment and risk reduction

UNI EN ISO 13857:2008

Safety of Machinery - Safety Distances to prevent danger zones being reached

by the upper and lower limbs (2008)

ISO 14120:2015

Safety of Machinery - Guards - General Requirements for the Design and

construction of fixed and movable guards

UNI EN ISO 13849-1:2016

Safety of Machinery - Parts of the Control System related to the Safety – Part 1:

General Design Principles

UNI EN ISO 14119:2013

Safety of Machinery - Interlocking devices associated with guards - Principles for

design and selection

CEI EN 60204-1/2016

Safety of Machinery - Electrical Equipment of Machines. Part 1: General Rules

(2010)

EN 61439-1:2011

Low-voltage Switchgear and Control Gear Assemblies. Part 1: General rules

FURTHER TECHNICAL STANDARDS APPLIED:

IEC EN 60335-1 "Safety of household electrical appliances and similar”

Electronic Ballasts for the control of the lamps in accordance with the standard EN 60928.

Germicidal UV-C Lamps in accordance with EN 61199.

Electrical Protective Measures in accordance with IEC 70-1, EN 60229.

Anghiari, 2.7.2019

Responsible for Standards: Dr. Aldo Santi

LIGHT PROGRESS S.r.l. Loc. San Lorenzo, 40 - 52031 ANGHIARI (AR) - ITALY -