Mechanical Specifications

5 -- 7

Liebert HPC---S 006---022---PD---273571---01.03.2012

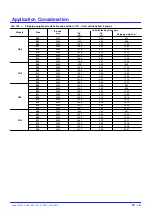

Tab. 5b --- 2 Pole, standard head pressure (data referred to each pump)

Models

006

007

009

011

014

015

018

019

022

CB0

Water Flow

m

3

/h

10.04

12.14

14.93

19.18

22.83

25.20

30.20

33.18

37.12

Available Pressure Head

kPa

103

99

87

81

103

81

44

113

100

CG0

Water Flow

m

3

/h

10.23

13.34

15.29

19.46

24.43

27.18

30.68

---

---

Available Pressure Head

kPa

101

84

83

78

89

61

37

---

---

Pump/s number

Nr.

1 / 2

Pump Rotor Model

---

CEA 210/2

CEA 370/1

CEA 370/2

FHE 40---125/22

Nominal Motor Power

kW

0.75

1.10

1.50

2.20

Noise Level

(*)

dB(A)

63

64

65

(*) --- According to ISO 3744

Tab. 5c --- 2 Pole, high head pressure (data referred to each pump)

Models

006

007

009

011

014

015

018

019

022

CB0

Water Flow

m

3

/h

10.04

12.14

14.93

19.18

22.83

25.20

30.20

33.18

37.12

Available Pressure Head

kPa

137

134

125

122

142

121

88

167

154

CG0

Water Flow

m

3

/h

10.23

13.34

15.29

19.46

24.43

27.18

30.68

---

---

Available Pressure Head

kPa

135

120

120

120

129

101

82

---

---

Pump/s number

Nr.

1 / 2

Pump Rotor Model

---

CEA 210/3

CEA 370/2

CEA 370/3

FHE 40---160/30

Nominal Motor Power

kW

1.10

1.50

1.85

3.00

Noise Level

(*)

dB(A)

63

64

65

66

(*) --- According to ISO 3744

Tab. 5d --- 2 Pole, standard head pressure (data referred to each pump)

Models

006

007

009

011

014

015

018

019

022

FB0

30% glycol---water Mixture Flow

m

3

/h

11.54

13.88

17.13

21.87

26.05

28.57

34.38

37.61

42.15

Available Pressure Head

kPa

46

69

90

69

61

83

60

86

52

FG0

30% glycol---water Mixture Flow

m

3

/h

11.84

15.53

17.59

22.32

28.04

31.09

35.19

---

---

Available Pressure Head

kPa

38

84

90

62

62

79

49

---

---

Pump/s number

Nr.

1 / 2

Pump Rotor Model

---

CEA

210/3

CEA 210/4

CEA

370/3

FHE

40---125/22

FHE 40---160/30

FHE 40---160/40

Nominal Motor Power

kW

1.10

1.50

1.85

2.20

3.00

4.00

Noise Level

(*)

dB(A)

63

64

65

66

67

(*) --- According to ISO 3744

Tab. 5e --- 2 Pole, high head pressure (data referred to each pump)

Models

006

007

009

011

014

015

018

019

022

FB0

30% glycol---water Mixture Flow

m

3

/h

11.54

13.88

17.13

21.87

26.05

28.57

34.38

37.61

42.15

Available Pressure Head

kPa

95

106

129

124

119

151

129

143

102

FG0

30% glycol---water Mixture Flow

m

3

/h

11.84

15.53

17.59

22.32

28.04

31.09

35.19

---

---

Available Pressure Head

kPa

87

122

129

117

118

147

118

---

---

Pump/s number

Nr.

1 / 2

Pump Rotor Model

---

CEA

210/4

CEA 210/5

CEA

370/5

FHE

40---160/30

FHE 40---160/40

FHE 40---200/55

Nominal Motor Power

kW

1.50

1.85

3.00

4.00

5.50

Noise Level

(*)

dB(A)

64

65

66

67

(*) --- According to ISO 3744

Содержание HPC-S 006

Страница 50: ......