6850000D

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

5 | EN

Pump Design

XLSG/XLSGX-Series grinder pumps are designed for continuous

underwater operation. The motor and pump form a close coupled,

watertight unit. The induction motor is insulated against heat and

moisture in accordance with Class F 311°F (155°C) regulations.

The motor is protected against damage from water entry by two

mechanical seals. The lower seal is 2-piece, silicon carbide/silicon

carbide and the upper seal is unitized graphite impregnated

silicon carbide.

The impeller and volute are designed for efficient flow

characteristics and clog-free operation. The hardened cutters

grind solids and fibrous matter into small particles that can be

safely pumped through small diameter piping.

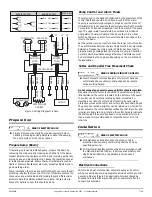

Pump System Components

Control Panel

Float switches must be connected to an intrinsically safe

circuit in the control panel as per the requirements of

Chapter 5 of the National Electric Code®.

XLSG/XLSGX-Series grinder pumps require a separate, approved

control panel for automatic operation. Operation will be

according to the control selected. Refer to separate

manufacturer’s instructions supplied with the unit.

The control panel shall be installed outside the hazardous area

and appropriately isolated and sealed to prevent any potential

ignition or explosion. Only approved controls that have

intrinsically safe float switch connections shall be used. Mounting,

installation and wiring connections are specific to the control

panel used. Refer to the manufacturer’s instructions supplied with

the unit.

IMPORTANT:

When connecting an XLSG/XLSGX-Series pump to

an existing control panel, verify the panel is correctly sized and

equipped for the pump.

The control panel for 3-phase pumps shall have provisions for the

thermostats that open the motor contactors in order to maintain

the T4 (135°C) temperature class. Do not exceed voltage/current

combinations for the thermostat: 16 VDC/20 Amps, 115 VAC/

22 Amps, 277 VAC/8 Amps, 600 VAC/4 Amps. All models have a

temperature (T) class rating of T4 with thermostats connected.

Failure to use the proper circuitry and to connect the thermostat

will void the T4 temperature class of the pump and will drop the

temperature class to T3 (200°C).

Intrinsically safe control panels designed for use with the XLSG/

XLSGX-Series pumps available from Liberty Pumps can be found

at http://www.LibertyPumps.com/Portals/0/Files/

panel_selection_guide.pdf or contact Liberty Pumps.

1-phase pumps require a panel-mounted start circuit consisting of

a start capacitor, run capacitor, and start relay, which are available

separately. Refer to Table 1 for these control panel components.

Overload Protection

XLSG/XLSGX-Series grinder pumps require overload protection in

the control panel. The motor control unit shall be approved and

shall be properly sized or adjusted for the full load input power

indicated on the pump nameplate. It is important to properly

adjust or select the motor control overload protection. The full

load amps on the nameplate should be used as a baseline, but it is

important to consider that events such as supply voltage variation

or large solids passing through the pump can temporarily increase

current draw. To avoid possible nuisance tripping, it may be

necessary to adjust overloads to a value slightly higher than the

full load input power indicated on the pump nameplate.

Thermostats

XLSG/XLSGX-Series grinder pumps are protected from

overheating by means of thermal switches (thermostat) located in

the motors. For 1-phase models, a hermetically sealed thermal

overload device is mounted on the motor windings and wired

directly in series with the motor’s winding, interrupting power in a

high heat condition. 3-phase models utilize two thermostats

mounted in series directly on the motor windings. The thermostat

circuit shall be connected to a control panel that will stop power

to the pump in a high temperature condition.

Both 1- and 3-phase pumps are constructed with class F materials,

with a maximum operation temperature of 155°C.

Failure to use

the proper circuitry and connection of the thermostat will drop

temperature class from T4 to T3 on 3-phase units

.

Many panels have a manual reset button for the thermostats on

3-phase units. This button must be pressed to reset the system

after the pump has cooled. 1-phase units reset automatically after

the pump has cooled.

RISK OF SERIOUS INJURY OR DEATH

Table 1. Control Panel Components 1-Phase

Required Component and Specification

Liberty Pumps

P/N

208 V 1-phase Start Kit

(contains 3 items listed separately below)

K001640

Start Capacitor, 270–324 µF 220/250 VAC

Run Capacitor, 65 µF 370 VAC

Start Relay

230 V 1-phase Start Kit

(contains 3 items listed separately below)

K001641

Start Capacitor, 270–324 µF 220/250 VAC

Run Capacitor, 50 µF 370 VAC

Start Relay