6 | EN

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

6850000D

Seal Failure Probes

XLSG/XLSGX-Series grinder pumps are equipped with two

mechanical face seals with an intermediate oil chamber between

them. This ensures lubrication for the seals, shaft flame path, and

as a barrier to the motor chamber in the event the lower seal is

compromised. A seal fail or moisture sensing device is located in

the mid oil chamber and continuously monitors for leakage. In the

event of a seal failure, moisture mixes with the oil, tripping the

seal leak circuit. In a failure condition, a fault light will illuminate

on the control panel. The pump will continue to operate, but

service should be scheduled as soon as possible.

Intrinsically safe (ISS and ISD) control panels by Liberty Pumps

have a seal leak test button that tests the integrity of the seal leak

circuit continuity. When pressed, the light should illuminate. The

light should go off when the test button is released. If it remains

on, the potentiometer is set too high. If light does not illuminate,

the light is burned out, the circuitry is open, or the system does

not have power. The seal leak relay requires adjustment upon

installation. See Seal leak relay setup on page 8.

Seal fail probes connect to a relay in the control panel, which is

included in a Liberty Pumps control panel. For a non-Liberty

Pumps control panel or for a replacement relay, refer to Table 2.

Power and Control Cords

Do not remove cord and strain relief, and do not connect

conduit to pump.

The power and control cords cannot be spliced; a junction box

may be used providing it is rated for hazardous locations and has

approved cord connectors.

IMPORTANT:

Each cord has a green lead. This is the ground wire

and must be grounded properly per NEC

®

and/or local codes.

Wiring Instructions

Always disconnect pump(s) from power source(s) before

handling or making any adjustments to either the pump(s),

the pump system, or the control panel.

All installation and maintenance of pumps, controls,

protection devices, and general wiring shall be done by

qualified personnel.

All electrical and safety practices shall be in accordance with

the National Electrical Code

®

, the Occupational Safety and

Health Administration, or applicable local codes and

ordinances.

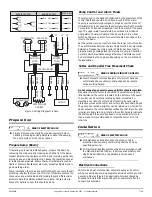

Figure 1. Wiring Diagram 1-Phase

Table 2. Seal Fail Replacement Relay

Description

Relay

Input

Voltage

Liberty

Pumps

P/N

Macromatic

P/N

Simplex, controls

1 pump

120V

K001672

SFP120A250

240V

K001673

SFP240A250

Duplex, controls

2 pumps

120V

K001675

SFP120C250

240V

K001676

SFP240C250

RISK OF ELECTRIC SHOCK

RISK OF ELECTRIC SHOCK

WHITE

WHITE

GREEN

BLACK

GREEN

GREEN

BLACK

GREEN

NOT

USED*

NOT

USED*

*

Note: on 1-phase pumps, the white and red leads of the

control cord are not used

SEAL

LEAK

BLACK

WHITE

RED

MOTOR

BLACK

WHITE

RED

RED

WHITE

GREEN

BLACK

L2/N

L1

RUN

CAP

START

CAP

POTTING

RESIN

SEAL

FAILURE

PROBES

START

RELAY

5 2

1

CONTROL

CORD

POWER

CORD

START CIRCUIT

START CIRCUIT