- 17 -

* First column : R adjustment data

display

* Second column : G adjustment

data display

* Third column : B adjustment data

display

6) Output the 240, 240, 240

(15th data in max white output signal level) in the VDP Test

Pattern, change the 15th RGB data value to come out

white valance x=283, y=294 and measured step luminance

in 5).

7) Output the 240, 240, 240 (14th data in max white output

signal level) in the VDP Test Pattern, change the 14th RGB

data value to come out white valance x=283, y=294 and

measured step luminance in 5).

8) As shown above, output the VDP Test Pattern signal

(208/192/176/160/144/128/112/96/80/64/48/32/16) and

change the RGB data value of each step to come out white

balance x=283, y=294 and measured luminance in 3).

(5) Sequence of Gamma manually adjustment

This is adjustment (after finish the 3-4) to check whether

Gamma/ White balance adjustment are well adjusted and

make correction manually.

1) Prepare the PC Pattern Generator which is possible to out-

put R/G/B of 16 step Gray Pattern.

2) Equipment composition : Follow <Fig. 2>.

3) Turn on the Jig for adjustment.

4) Select the RGB_PC by pressing the input select button on

Remote Control.

5) Output the 16 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

White balance is right about each Gray.

If it’s not, press the ADJ button on Remote Control and

then adjust the level data of each step manually.in “Gamma

adjust”.

6) Output the 64 Gray Pattern in PC Pattern Generator.

Check it with the naked eye whether Screen Gamma and

White balance is right about each Gray or whether there is

Gamma noise.

If there’s any problem, adjust in 5)

7) After finishing adjustment, exit adjustment mode by using

ADJ button on Remote Control.

6-5. White Uniformity Adjustment

(1) Required Test Equipments

1) Uniformity measuring equipment : Equipment which can

measure chromatiity in the whole screen

2) Set stand : 1EA

3) Remote controller for adjustment : 1EA

4) Circuit thing Jig for Adjustment (Except Driver Board Assy

of adjustment model)

--- Programmed Digital Board so that the VDP Test Pattern

can output white signal by 1level form 0 to 255 level.

(2) Equipment composition

Compose the equipment as Fig.2

(3) Preparation for Adjustment

1) Composite the equipment as shown Fig.2, and place the

set on fixation stand.

2) After inputting company channel 13, adjust colour uniformity

like Horizontal/ Vertical position adjustment of input signal

part adjustment by using remote control for adjustment.

3) After pressing IN_START key on remote control for

adjustment, select the adjustment mode 7050 Uniformity.

<Resister Explanation about uniformity adjustment>

1. RamCtrl : s/w saving uniformity write order (Do not adjust)

2. CSHP : Horizontal start point designation --- adjustable

3. CSVP : Vertical start point designation --- adjustable

4. CEHP : Horizontal END point designation --- adjustable

5. CEVP : Vertical END point 6.designation --- adjustable

6. Mode : uniformity mode select --- adjustable if need

*** 0 : 221point & 3level ---- defalut value

*** 1 : 221point & 4level

*** 2 : 825point & 3level

*** 3 : 825point & 4level

7. KHH : Upper 2byte of horizontal line correction coefficient --

Change according to CSHP, CEHP value.

8. KHL : Upper 2byte of vertical line correction coefficient --

Change according to CSHP, CEHP value.

** How to calculate KHH, KHL value

LCD panel size = 1280 x 720

Correction Point = 221 point

--> 17 horizontal points x 13 vertical points

(16 horizontal segments x 12 vertical poins)

O

H Coefficient(KHH, KHL)

--> Calculation method (CEHP-CSHP=1280, Horizontal

segment value =16)

9. KVH : Upper 2byte of vertical line correction coefficient

-- Change according to CSVP, CEVP value.

10. KVL : Upper 2byte of vertical line correction coefficient

-- Change according to CSVP, CEVP value.

O

V Coefficient(KVH, KVL)

Calculation method (CEVP-CSVP=720, Vertical segment

value =12)

11. RL1H : Upper 9bit of MID2 brightness correction

coefficient in R MIN.

--- Change according to RMIN and RMID2 value.

12. RL1L : Lower 9bit of MID2 brightness correction coefficient

in R MIN.

--- Change according to RMIN and RMID2 value.

13. RL2H : Upper 9bit of MID1 brightness correction

coefficient in R MID2.

--- Change according to RMID2 and RMID1 value.

H coefficient = 1/(number of pixel intervals between setting in the horizontal

direction)

Hcoeff = 1/((1280/16)-1) = 0.012658227

hex (0.012658227 x 2

16

) = 0 x 033D, Hcoeff (hex) = 0 x 033D + 1 = 0 x 33E

V coefficient = 1/(number of pixel intervals between setting in the vertical

direction)

Vcoeff = 1/((720/12)-1) = 0.016949152

hex (0.016949152 x 2

16

) = 0 x 0456, Vcoeff (hex) = 0 x 0456 + 1 = 0 x 0457

Gamma Adjust

R:1

G:2

B:3

80

100

100

234

216

216

453

411

387

--------------------------

--------------------------

724

690

780

Содержание RT-52SZ30RB

Страница 24: ... 24 5 General Control Signal ...

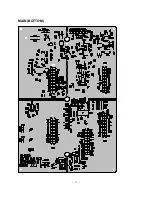

Страница 25: ... 25 PRINTED CIRCUIT BOARD MAIN TOP ...

Страница 26: ... 26 MAIN BOTTOM ...

Страница 27: ... 27 COMPONENT TOP COMPONENT BOTTOM SIDE A V PRE AMP LED AC INPUT ...

Страница 28: ... 28 LCD DRIVER TOP CONTROL ...

Страница 29: ... 29 LCD DRIVER BOTTOM ...

Страница 30: ... 30 DIGITAL BOTTOM DIGITAL BOTTOM ...

Страница 31: ... 31 TUNER TOP TUNER BOTTOM ...

Страница 32: ... 32 SMPS POWER S W INTERFACE BALLAST ...

Страница 33: ...MEMO 33 ...

Страница 46: ...P No 3854VA0117A S1 1 2 2003 6 21 ...

Страница 47: ...P No 3854VA0117A S1 2 2 2003 6 21 ...

Страница 48: ...P No 3854VA0117A S2 1 2 2003 6 21 ...

Страница 49: ...P No 3854VA0117A S2 2 2 2003 6 21 ...

Страница 50: ...SVC SHEET 3854V A0117A S1 SVC SHEET 3854V A0117A S2 SVC SHEET ...