57

Troubleshooting

Sometimes unavoidable issues will occur while operating the RTP 118

®

. Fortunately, there are

several methods to remedy these issues.

Common Machine/Part Issues

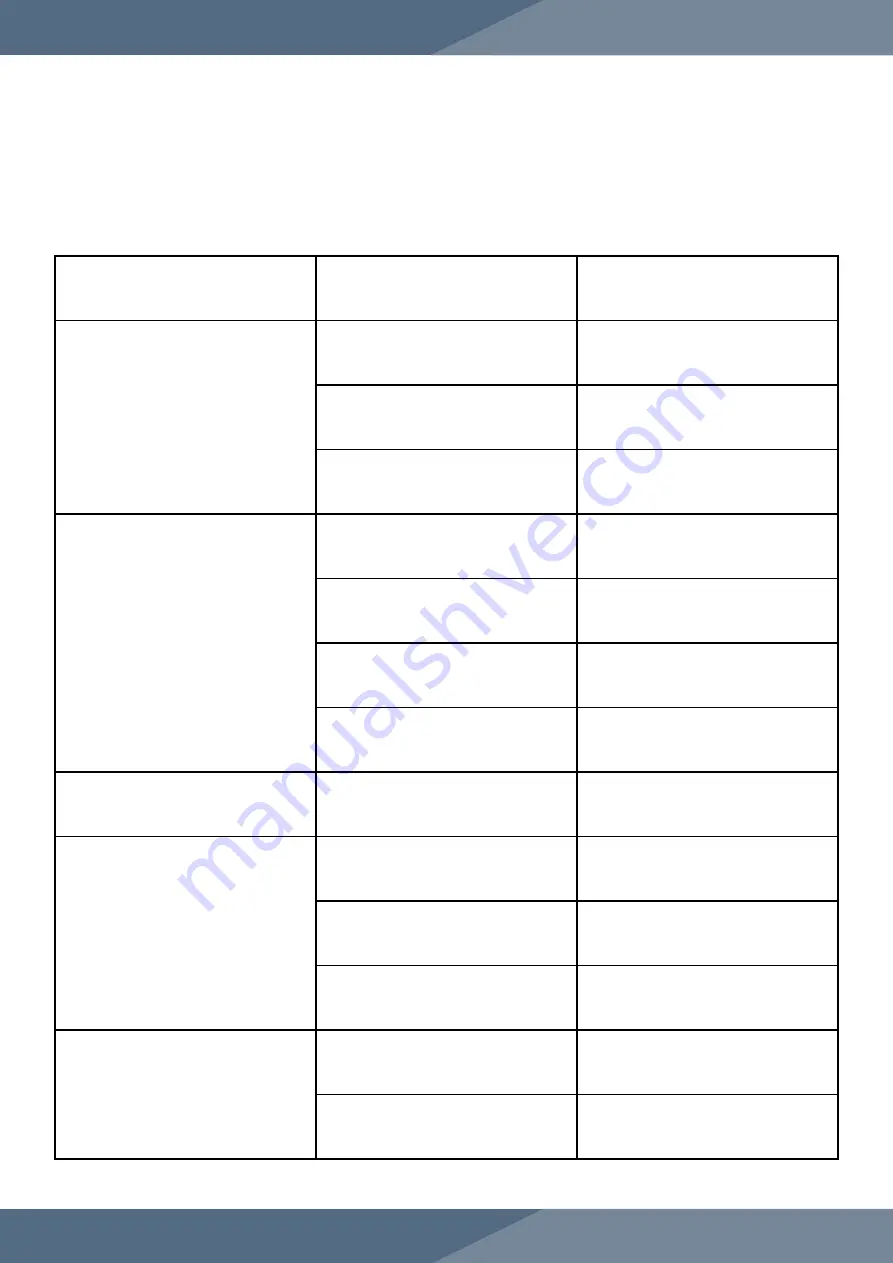

Symptom

Possible Cause

Possible Solution

Machine freezes or locks up

Grease point areas are dry.

Regularly oil and grease all the

Grease Nipples and high friction

areas.

There is excess pressure.

Rotate the Pressure Knob on the left-

hand side of machine clockwise.

There is caking of powder in the

machine.

Take apart the Turret and Tooling and

clean.

Knocking sounds coming from

machine

There is excess pressure.

Rotate the Pressure Knob on the

left-hand side of the machine

counterclockwise.

The V Belts are loose.

Replace the V Belts.

Parts may be loose.

Check the machine's parts and

tighten as necessary.

The Gearbox needs oil.

Check the Gearbox's oil level and

lubricate if necessary.

Heavy resistance during production

The high friction areas are either

unclean, locked, worn out, or not

greased properly.

Apply grease to the Grease Nipple

points and all high friction areas and/

or clean the machine.

Excess machine vibration

The V Belts are worn.

Replace the V Belts.

The machine has no anti-vibration

pads or they are worn.

Place new anti-vibration pads on the

bottom of the machine.

Parts may be loose.

Check the machine's parts and

tighten as necessary.

Excess powder waste

The dry materials are moving too fast. Lower the rotation speed.

The Fill Tray is too high or unleveled.

Adjust the Fill Tray and Fill Tray

Scrapers accordingly.

Содержание RTP 118

Страница 1: ...1 We don t just sell machines we provide service RTP 118 Tablet Press User Manual ...

Страница 12: ...12 The shipping crate will contain the following 1 The assembled RTP 118 2 The Tooling already installed ...

Страница 38: ...38 6 Pull the Upper Punch upwards to remove it from the Turret ...