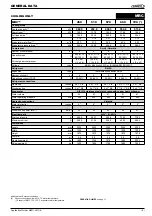

V

Q

Dt

MWC

180

4

645

230

5

659

280

6

669

330

5

946

380

4

1362

450

6

1075

510

6

1218

570

6

1362

650

6

1553

720

6

1720

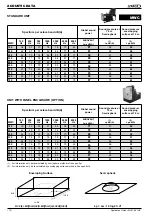

+ 5°C

►

0°C

10%

1,05

1,02

0,99

0,994

0°C

►

-5°C

20%

1,10

1,05

0,98

0,993

- 5°C

►

-10°C

30%

1,15

1,08

0,97

0,99

- 10°C

►

-15°C

35%

1,18

1,10

0,96

0,987

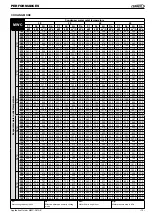

Application Guide

•

MWC-0410-E

• 11 •

HYDRAULIC DATA

Vmini = 86 x Q / (Nstages x Dt)

Where :

Minimum water content of the installation

Cooling capacity of the chiller

Nstage

Number of control steps available in the unit

Maximum acceptable temperature rise (Dt = 6°c for an air conditioning application)

Important note: In case MWC™ is used in air-conditioning applications with a short water system (e.g. MWC™ application with air

handling units) or in case MWC™ is used for industrial process cooling, it is mandatory to use a buffer tank.

MINIMUM WATER CONTENT OF AN INSTALLATION

Thanks to multi step capacity control and smart anti-short compressor cycling, MWC™ can work with minimum water loop volume

as de

fi

ned here below. This can eliminate the need for a buffer tank in most of air-conditioning applications (e.g. MWC™ application

with fan-coil units). :

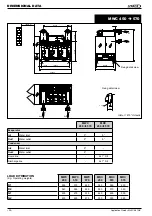

Unit Size

Number of stages

Mini water volume (l)

MINIMUM WATER CONTENT OF AN INSTALLATION

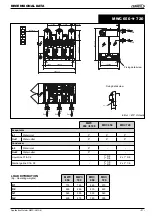

GLYCOL CORRECTION FACTOR

Example : 10% glycol

Minimum

fl

ow : 1,19 m

3

/h x 1,02

Pressure drop x 1,07

System capacity x 0,99

Minimum ambient temperature or water

outlet temperature

Ethylene

glycol

Pressure

drop

Water

fl

ow

CAPACITIES

Cooling

Heating

Note : The volume of the condenser water loop has no impact on the chiller operation. In heat pump operation (with hot water set point control option)

the minimum volume of the condenser water loop must be calculated based on the heating capacity using the same formula.