20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Turn on gas supply and test for gas leaks using a gas leak test solution (also

referred to as bubble leak solution).

Note:

Using a soapy water solution

(50% dish soap, 50% water) is an effective leak test solution but it is not

recommended, because the soap residue that is left on the pipes/fittings can

result in corrosion over time.

A. Light the appliance

(refer to the lighting instructions provided in the

Homeowner's Care and Operation Instructions).

B. Brush all joints and connections with the gas leak test solution to check for

leaks. If bubbles are formed, or gas odor is detected, turn the gas control

knob (off/pilot/on) to the “OFF” position. Either tighten or refasten the

leaking connection, then retest as described above.

C. When the gas lines are tested and leak free be sure to rinse off the

leak testing solution,

D. Turn on burner then observe the individual tongues of flame on the burner.

Make sure all ports are open and producing flame evenly across the burner.

If any ports are blocked, or partially blocked, clean out the ports.

WARNING

Never use an open flame to check for leaks.

Right

Front Twig

Embers

Figure 28

8.

Install the front right twig onto the corresponding pin on the right

front log. Align the twig with the indentation on the front right log as

shown in

Figure 27

.

9.

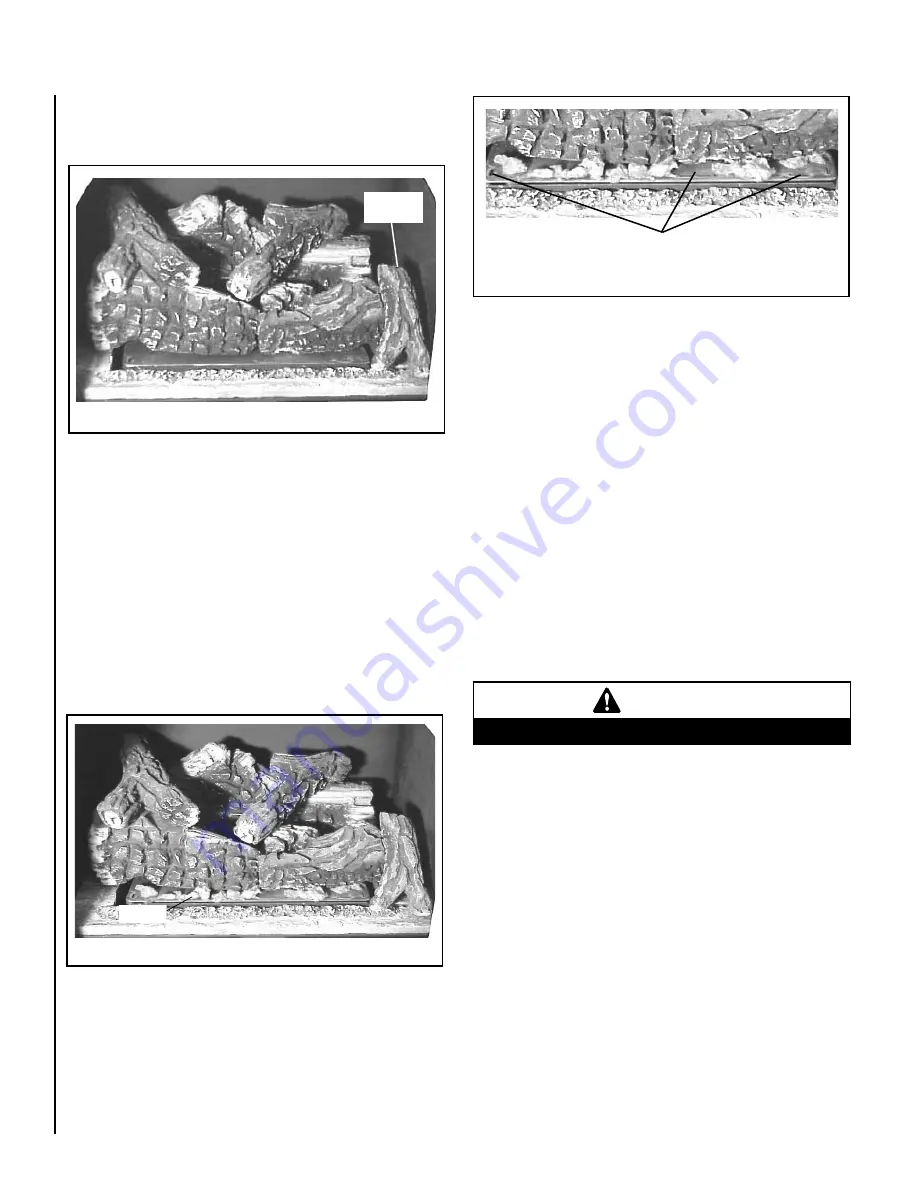

Place the glowing embers on the burner as shown in

Figures 28

and 29

.

One package of ember material has been included with this log set

You will not need to use the entire bag.

IMPORTANT: The quantity and placement of the ember material can

affect stove performance therefore it is very important that it be placed

as shown in

Figure

s 28 and 29

.

a. Unpackage and divide the fine ember material (mineral wool) into

dime-sized fluffy pieces.

b. Distribute the pieces over the top of the front burner ports avoiding

covering the slots (see

Figure 29

)

and filling the area in front of the

forward logs.

Figure 27

VERIFY THAT THE GAS LINE HAS BEEN PURGED OF AIR (SEE STEP

10).

Step 12. RE-INSTALL FRONT GLASS ENCLOSURE PANEL

(Reverse instructions on Step 4)

Retrieve the front glass enclosure panel. Visually inspect the gasket

on the backside of the frame. Gasket surface must be clean, free of

irregularities and seated firmly.

With the stove top off, position the glass front enclosure panel into

the front opening with the gasket facing the relief door (reference

Figures 8 and 9

)

. Let the bottom of the door frame gently slide

down, then hook the top flange of the glass frame over the top of

the firebox frame.

Fasten the two latches located beneath the firebox floor to the glass

frame vee-flange. Close both the latches securely.

Step 13. TEST ALL CONNECTIONS FOR LEAKS (FACTORY AND

FIELD).

DO NOT PLACE EMBERS ON TOP OF THE BURNER SLOTS.

Figure 29

Содержание CI1500DVF Series

Страница 25: ...25 notes ...