Technical Data

LHS SYSTEM

20S

20L

40S

40L

60S

60L

Voltage

V~

100 – 230

200 – 230

100 – 230

3

×

230 – 3

×

440 3

×

230 – 3

×

480 3

×

230 – 3

×

480

Frequency

Hz

50/60

50/60

50/60

50/60

50/60

50/60

Power

consumption kW

1.0 / 2.0

3.3

2.0 / 4.0

2.0 / 4.0

4.0 / 6.0

5.0 – 16.0

Air flow

l/min.

min. 100

min. 200

min. 200

min. 200

min. 300

min. 400

Temperature °C

max. 650

max. 650

max. 650

max. 650

max. 650

max. 650

Ambient

°C

temperature

<

65

<

65

<

65

<

65

<

65

<

65

Weight

kg

0.55

0.65

0.85

0.95

3.15

3.65

Size

mm

237

×

97

×

92 267

×

97

×

92 246

×

112

×

103 276

×

112

×

103 379

×

116

×

137 379

×

116

×

137

Mark of conformity

¬

¬

¬

¬

¬

¬

Marl of approval

†

†

†

†

†

†

Certification scheme

CCA

CCA

CCA

CCA

CCA

CCA

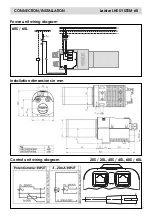

Protection class I

‡

‡

Protection class II

¶

¶

¶

¶

2

Danger!

When opening up the tool, live components and

connections are exposed. The mains plug must be removed

from the main socket before opening up the tool.

Caution

separate source voltage.

Incorrect installation and use of air heaters can present

a

fire and explosion hazard

, particularly in the proximity of

flammable materials and explosive gases.

Do not touch the element housing and nozzle when hot

as they can cause

burns.

Do not point the hot air flow at

people or animals.

WARNING

The tool must be operated

with supervision

. Warmth can

reach combustible materials, which are out of sight.

The

voltage rating

stated on the tool should correspond

to the mains voltage.

IEC/EN 61000-3-11; Z

max

=

0.047

Ω

+ j 0.029

Ω

. If necessary,

consultate supply authority.

Protect the tool from

dampness

and

wet

.

100

480

CAUTION

The tool with protection class I should be earthed using a

protective conductor.