EM415S Digital Stepper Drive User Manual

Motion Control Products Ltd.

Tel.: (+44) 01202 599922

For a given stepper motor, as normal setting the output current to 1.4 times of motor phase current, will make it

output larger torque, but at the same time cause more heating for both the motor and drive. Therefore, it is

suggested to set a output current

(peak of sinusoidal) to no more than 1.2 times the stepper motor’s

(for 4-lead

motor) phase current to prevent overheating .

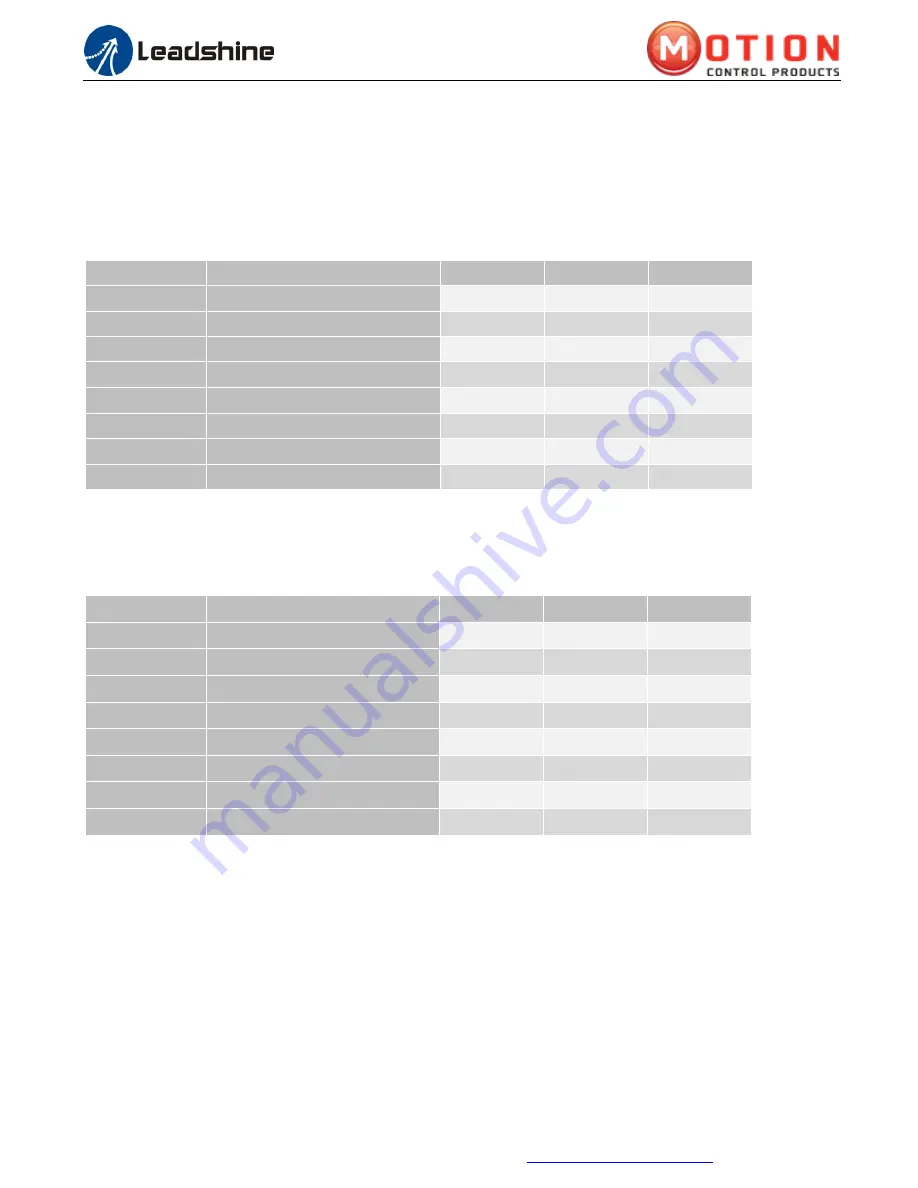

The SW1, SW2 and SW3

are used to set the dynamic current. Select a setting closest to your motor’s required curr

ent.

When they are set to

ON, ON, ON,

the output current can be set by Leadshine ProTuner.

Peak Current

RMS Current

SW1

SW2

SW3

0.3A

0.21A (default)

ON

ON

ON

0.5A

0.35A

OFF

ON

ON

0.6A

0.42A

ON

OFF

ON

0.7A

0.49A

OFF

OFF

ON

0.8A

0.57A

ON

ON

OFF

1.0A

0.71A

OFF

ON

OFF

1.2A

0.85A

ON

OFF

OFF

1.5A

1.06A

OFF

OFF

OFF

7.2 Micro Step Configuration (SW4-6)

Each EM415S has 8 micro step settings which can be configured through DIP switch SW4, SW5, SW6. See the

following table for detail. When they are set to

ON, ON, ON

, the microstep can be set via Leadshine ProTuner.

Micro step

Pulses/Rev. (for 1.8°motor)

SW4

SW5

SW6

1

200 (default)

ON

ON

ON

2

400

OFF

ON

ON

4

800

ON

OFF

ON

8

1600

OFF

OFF

ON

16

3200

ON

ON

OFF

32

6400

OFF

ON

OFF

64

12800

ON

OFF

OFF

128

25600

OFF

OFF

OFF

7.3 Pulse Mode Configuration (SW7)

DIP switch SW7 is used to configure the control mode. Factory setting is single pulse (step & direction, or pulse &

direction) control. Setting to ON to change the control model to double pulse (CW/CCW) control type.

7.4 Self-Test Configuration (SW8)

For test and system diagnosis purpose, EM442S is featured with Self-Test. Anytime DIP switch SW8 is switched to ON

position, the drive will automatically rotate the driven stepper motor back and forth for one round in each direction.

Set this switch position to OFF for normal operation.