Page 12

PROTECTOR® IV Gauge Face Installation, Operation & Maintenance Manual

13.

Secure the mounting bolts to the clamp blocks tightening the right bolt first to ensure the wiping bar is

pushed securely against the rail.

14. Occasionally tap the assembly as you are tightening to insure wiping bar remains tight to the rail.

15. Torque mounting bolts to approximately 200-250 ft.-lbs. (340 N-m).

Note: Tapping assembly with a hammer ensures the wiping bar remains in contact with rail gage face. Ensure

wiping bar remains tight to rail as mounting bolts are being tightened.

16. Install the wiping bar supply hoses, directing the free ends towards the central supply point. After tightening

the hoses, turn wiping bar inlet elbow slightly so that the supply hoses are directed smoothly downward

towards the top of the sleepers.

After full installation and initial testing the wiping bar should be assessed to check that it is set at the correct

height. As mentioned before, if the bar is set too high it is likely to be damaged by passing wheel flanges and

if set too low the lubricant will not be picked up properly by the wheel flanges. If either is the case, step #12

should be repeated to reset the height.

MC-4® XL Grease Bar Installation

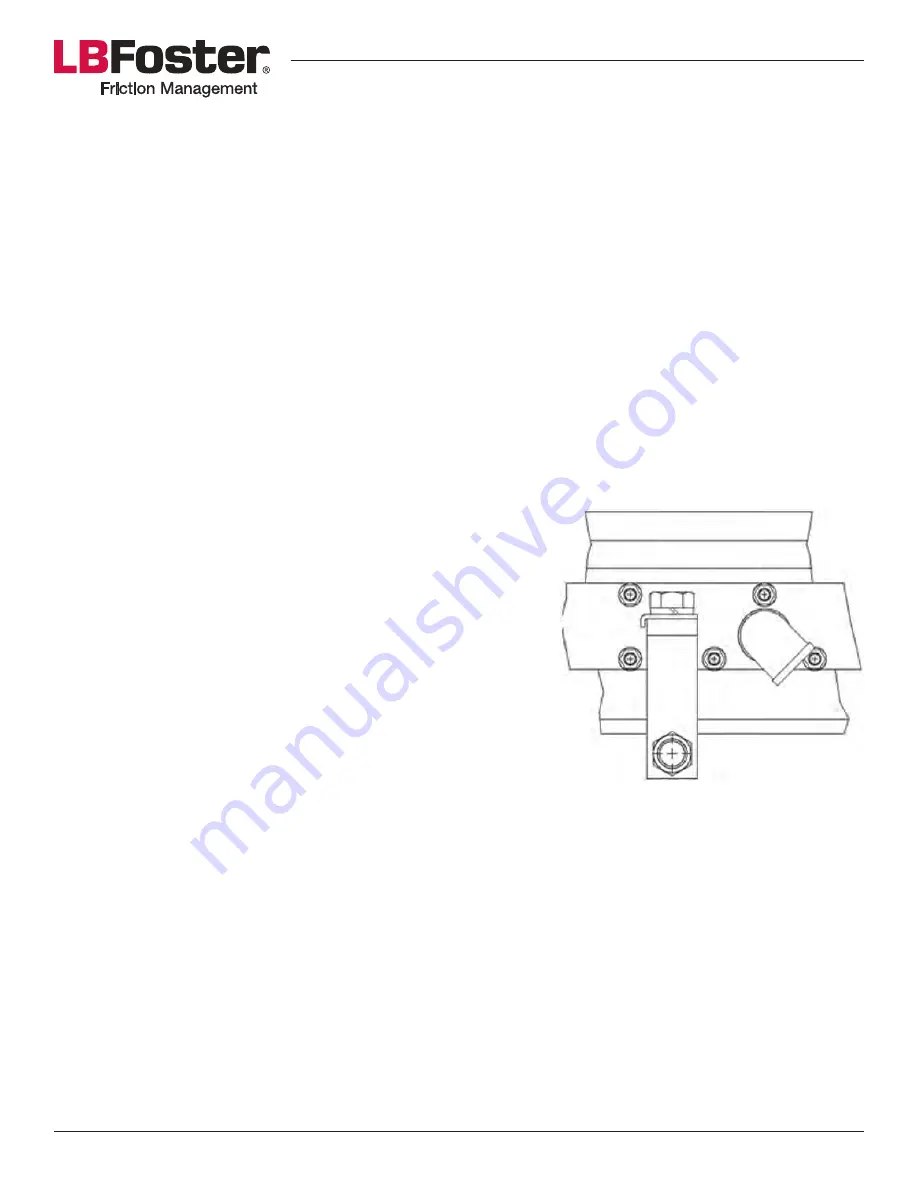

The MC-4XL wiping bars are similar to the MC-4 bars, but have been

extended to 55” (1.4 m) length to provide additional distribution of

grease.

In a four bar arrangement, MC-4XL bars can only be installed on

tangent track. In a two bar arrangement, MC-4XL bars can be

installed early in the transition when two bars are to be installed

on one or both rails, they should be positioned end to end, or

as close as possible. This insures lubrication of the entire wheel

for maximum grease coverage. Install these bars using the same

instructions as provided on the configuration page. The only extra

requirement when installing the MC-4XL bars is that they should

be installed with an extra clamp in the center of the bar to ensure

the bar is pushed fully against the gage face of the rail. Install this

clamp behind the curve of the inlet elbow to avoid obstructing the

inlet hose (see

Figure 3

). Once the wiping bars have been installed using the same procedure as described

earlier, the extra clamp can be secured to the rail and the rectangular spacer can be pushed against the middle

of the bar, then the mounting bolt secured to hold the spacer in place.

Distribution Hose Installation

Install one main supply hose and four grease distribution unit hoses as follows:

1. Run main supply hose from tank, underneath the rail, to a position central to wiping bar assemblies.

2.

Layout the “H” configuration of valves with main hose and distribution hoses.

3.

Thread the main supply hose to the “H” configuration of valves at center track.

4.

Thread each hose between “H” configurations of valves to an individual wiping bar.

Note: Hoses supplied by the customer must be non-conducting, this ensures the hose system will not shunt signals.

Figure 3: MC-4XL Center Clamp Position