Defender Press Brake Guarding System Operation Manual

LS-CS-M-069

Page 7

Original Language Version: 1.04

Released:

01/04/2020

These sensors are divided into three zones that represent the front, middle and rear of the

laser plane (the

FR

,

MI

,

RE

signals). If an obstruction blocks the laser light to any of the

sensors, the receiver will turn off the appropriate signal, and the PGS-2 controller will

immediately disable downward movement of the press beam.

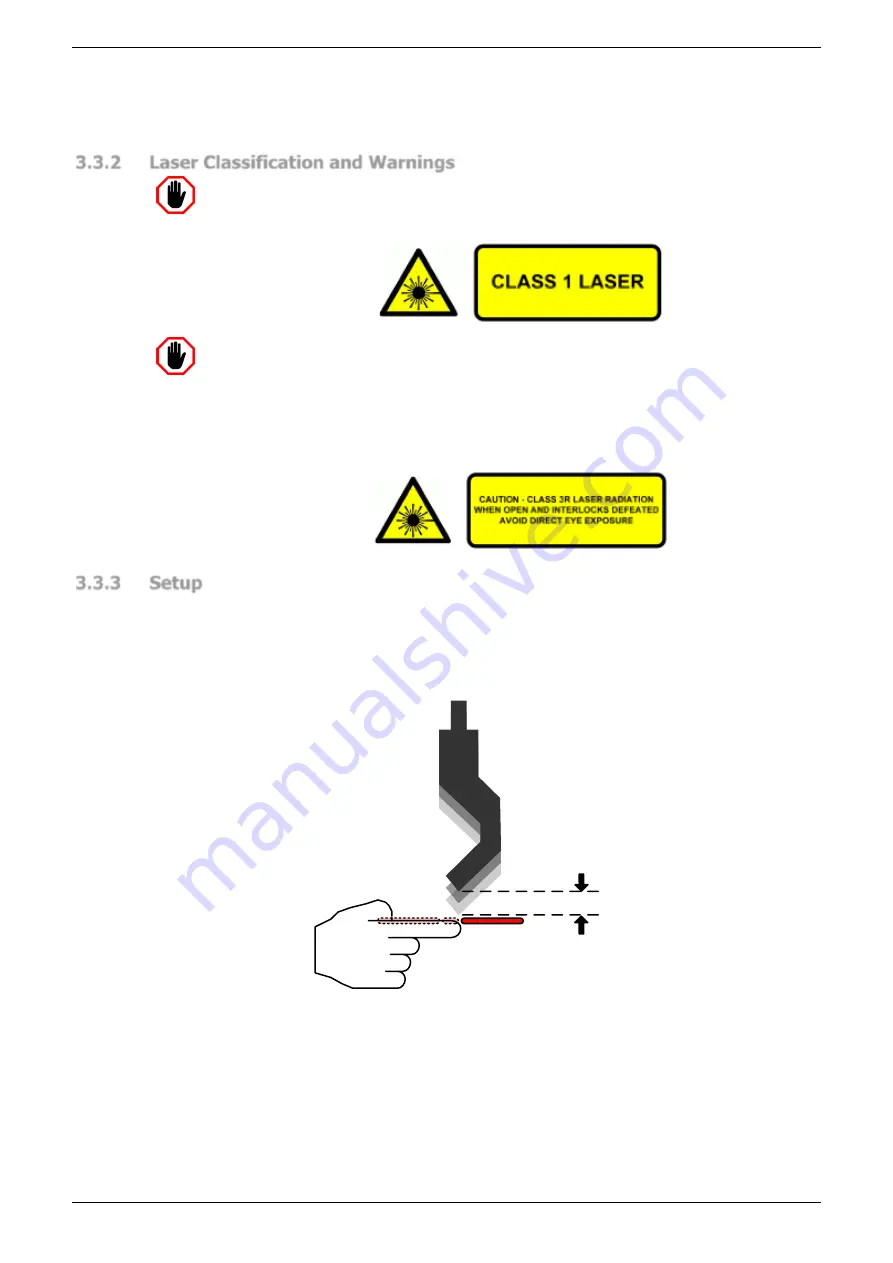

3.3.2

Laser Classification and Warnings

Warning: CLASS 1 LASER DEVICE

The LZS-1 laser transmitter emits CLASS 1 planar laser light approximately

50mm in width. Do not stare directly into the laser or the transmitter window.

Warning: CLASS 3R LASER RADIATION: DO NOT OPEN OR TAMPER WITH

THE LASER TRANSMITTER

The LZS-1 laser transmitter contains no user serviceable components. Do not

attempt to tamper with, or dismantle the laser transmitter as this will void the

product warranty and may expose you to the internal laser emitter CLASS 3R

LASER RADIATION that has the potential to cause eye damage.

3.3.3

Setup

Prior to operating the machine, and after a tool change, it is necessary to check that the laser

is set to the correct distance below the punch tip. The laser to punch distance is configured

during installation of the system, according to the maximum stopping distance of the machine,

so that when an obstruction occurs the machine can stop before the tool tip reaches the

obstruction, see

Stopping

Distance

Figure 3-3: Stopping Distance

The stopping performance of the machine is measured by an overrun test at start-up, and is

automatically monitored relative to the laser to punch setting on every machine stop. If the

machine is operated continuously, the overrun test is repeated every 24 hours.

The laser to punch distance setting for your machine can be viewed in the Operator Panel by

navigating to the System Information screen (see

Section 5.7.1

MAIN

➔

INFO

➔

SYSTEM INFO