GUARANTEE

We guarantee the Lawler Mixing Valve to be free from def ects in workmanship and material, and for

a period of one year from date of purchase, will replace any parts found by us to be defective. We will

not be held responsible, however, for any labor incidental to, or for any damages caused by defective

material. Each mixing valve is thoroughly inspected and tested under actual conditions at our factory.

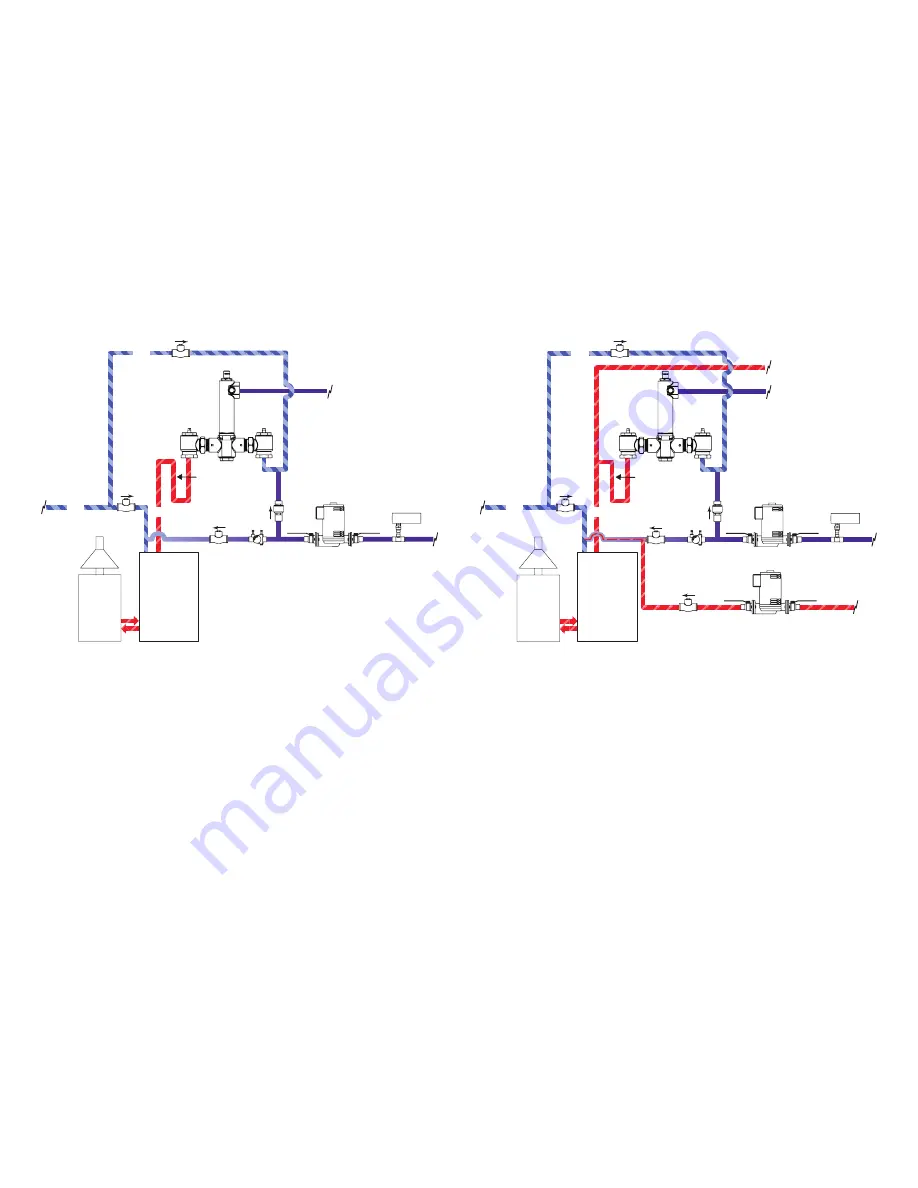

Typical Installation

Install the mixing valve below the hot water tank or heater.

If this is not possible, pipe in a heat trap as shown in

Figure 1 with an approximate 2’ drop.

Connect a tempered water return line as shown in

Figure 1. This allows flow through both ports of the mixing

valve during periods of no draw.

If a dual temperature system is used, a separate

recirculating loop and pump are required to return high

temperature hot water to the water heater. See Figure 2.

Install an aquastat at the tempered water return pump.

Install the water heater per manufacturer’s instructions.

Setting The Mixing Valve To The System

1. After installations be sure to flush the system thoroughly.

2. Make sure the hot water supply is heated to normal

design temperature.

3. Close and tag all fixtures to ensure they are not used

during this procedure.

4. Turn off the recirculating pump.

5. Create a draw on the system greater than the minimum

flow rating of the mixing valve. All open fixtures must be

tagged to ensure they are not tampered with or used

during this procedure.

6. Allow water to flow through the mixing valve until the

water temperature is stable. If necessary, readjust the

mixing valve in accordance with the TEMPERATURE

ADJUSTMENT section of the installation manual.

7. Once the temperature is set, start the recirculating pump

and allow the system to reach set temperature.

8. Measure the water temperature at the return pump

and adjust the aquastat to shut off the pump should

the return water exceed the set point by 2 degrees

F. Set the low limit switch to restart the return pump

when return water drops 5 degrees F below the set

temperature.

9. Set the balancing valve in the full open position.

10. Shut off all fixtures and ensure there is no draw on the

system. The cold inlet to the mixing valve should be

warm.

11. Allow the system to run in this condition for at least 30

minutes.

12. In some cases, an increase in water temperature may

occur during a no draw period. If this occurs, slowly

close the balancing valve until the water temperature is

back to the original set temperature.

STORAGE

TANK

WATER

HEATER

HEAT TRAP

27” DROP

RECIRCULATION

PUMP

AQUASTAT

BALANCING

VALVE

CW

CW

HW

CV

CV

CV

CV

TO LOW

TEMPERATURE

FIXTURES

Water heater must

be installed per

manufacturers O+M

STORAGE

TANK

WATER

HEATER

HEAT TRAP

27” DROP

RECIRCULATION

PUMP

AQUASTAT

BALANCING

VALVE

CV

CW

CW

HW

CV

CV

CV

CV

TO LOW

TEMPERATURE

FIXTURES

TO HIGH

TEMPERATURE

FIXTURES

RECIRCULATION

PUMP

Water heater must

be installed per

manufacturers O+M

Figure 1

When used in a single temperature

recirculating system

Figure 2

When used in a dual temperature

recirculating system