Table Of Contents

1 - Introduction

1.1

1.2

1 - Introduction

1.1 - Your New FMM-3 Paper Drill

1.2 - Shipping Damage Inspection

Remove the machine from the carton and inspect for

any shipping damage. If any damage is present, report

the damage to the carrier immediately; failure to do so

may void any warranties.

Page 01

Page 01

R

Page 01

Your New FMM-3 Paper Drill................

Shipping Damage Inspection...............

2 - Safety

2.1

2.2

2.3

Page 02

Page 03

Page 04

Safety Instructions................................

Warning Labels.....................................

Grounding Instructions.........................

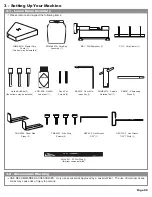

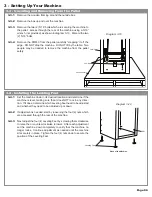

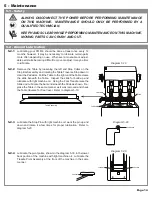

3 - Setting Up Your Machine

3.1

3.2

3.3

3.4

3.5

3.6

3.7

Page 05

Page 05

Page 06

Page 06

Page 07

Page 07

Page 07

Loose Items Inventory..........................

Accessories Warning............................

Uncrating and Removing From the

Pallet....................................................

Installing the Leveling Feet..................

Attaching the Paper Side Stops...........

Attaching the Chip Bag........................

Electrical Instructions...........................

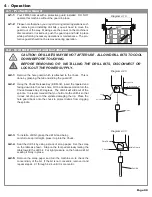

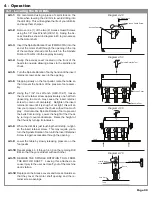

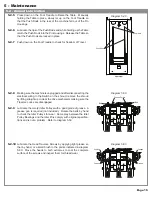

4 - Operation

4.1

4.2

4.3

4.4

4.5

4.6

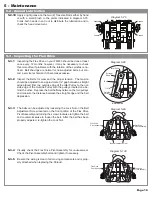

4.7

4.8

4.9

4.10

4.11

Page 08

Page 08

Page 09

Page 10

Page 10

Page 11

Page 11

Page 12

Page 12

Page 13

Page 13

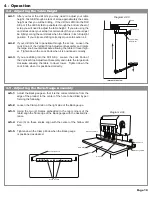

Protective Guard..................................

Drill Bit Removal and Installation.........

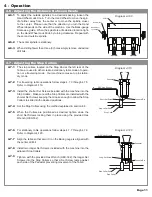

Leveling the Drill Bits............................

Adjusting the Table Height...................

Adjusting the Back-Gauge Assembly...

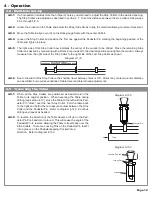

Adjusting the Distance Between

Holes....................................................

Adjusting the Stop Collars....................

Multi-hole Set-up..................................

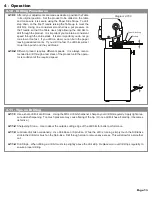

Traversing the Table.............................

Drilling Procedures...............................

Tips on Drilling......................................

5 - Maintenance

5.1

5.2

5.3

Page 14

Page 14

Page 16

Safety....................................................

Annual Lubrication................................

Inspecting the Flex Drive......................

6 - Trouble Shooting Guide

6.1

Page 17

Determining the Cause and Correction

to Certain Problems..............................

Thank you for your purchase of the Spinnit FMM-3

Paper Drill.

We ask that you take a moment to fill in the serial

number and other information on the front cover of the

manual. Please keep this manual as a reference for

future use.

For parts and service, please contact the Lassco-Wizer

Dealer from whom you purchased the machine. If you

require assistance in locating a Lassco-Wizer Dealer

please contact our customer service department at 585-

436-1934. Please have the model of your machine and

the serial number when you call.

If you wish to write to us, send correspondence to:

Lassco-Wizer

Attn: Customer Service

485 Hague Street

Rochester, NY 14606

7 - Parts Diagrams

7.1

7.2

7.3

7.4

7.5

Page 20

Page 21

Page 22

Page 23

Page 24

Side View.............................................

Head Assembly.....................................

Spindle and Chuck Assembly...............

Rear View.............................................

Parts List..............................................

Содержание Spinnit FMM-3

Страница 21: ...7 Parts Diagrams 7 1 Side View Page 20 ...

Страница 22: ...7 Parts Diagrams 7 2 Head Assembly Page 21 ...

Страница 23: ...7 Parts Diagrams 7 3 Spindle and Chuck Assembly Page 22 ...

Страница 24: ...7 Parts Diagrams 7 4 Rear View Page 23 ...