18

EXCALIBUR LINER

English

Ref. 20144

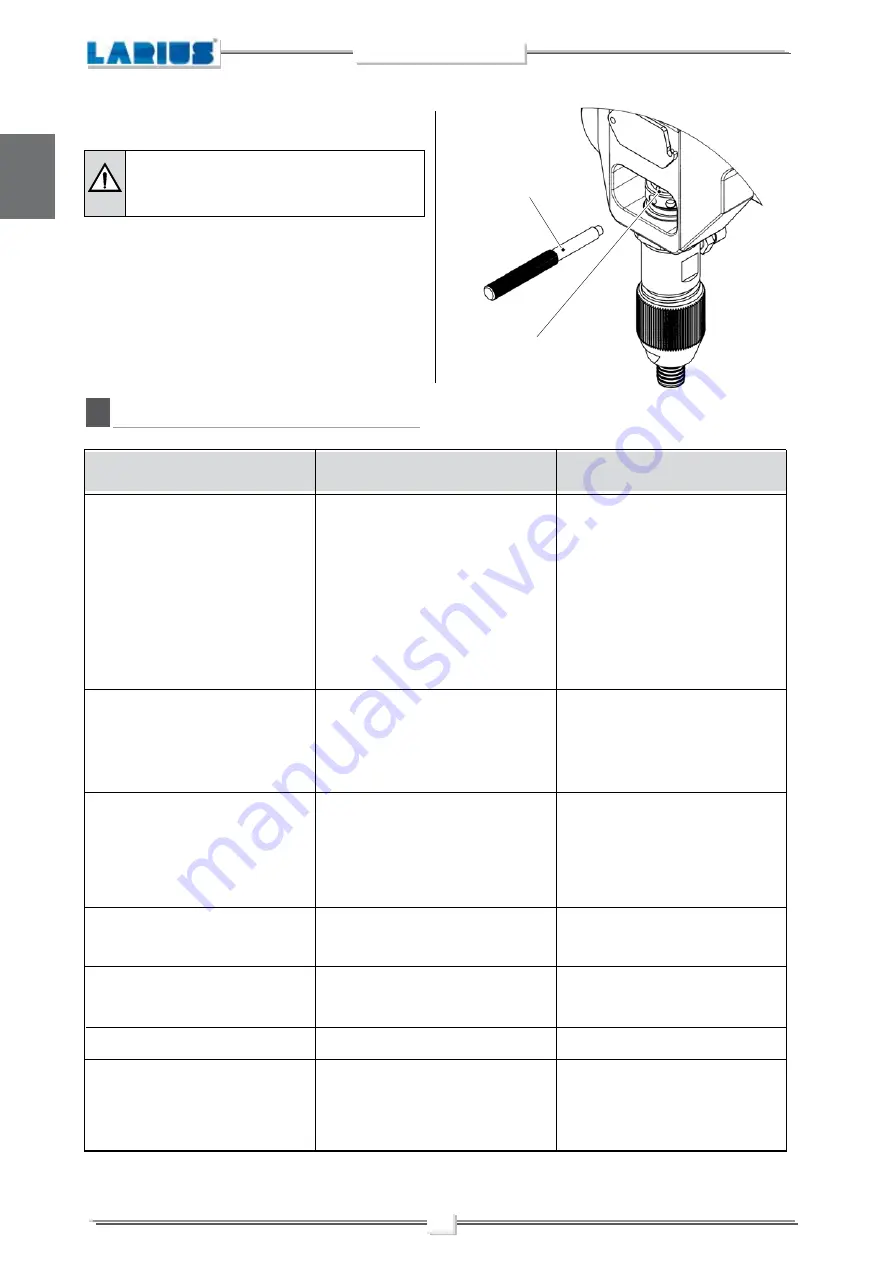

Closing/opening

pin

• For tightening, use the wrench supplied

(ref. 11503)

.

L

PROBLEMS AND SOLUTIONS

Solution

Cause

Problem

•

The equipment does not start

•

The equipment does not suck the

product

•

The equipment sucks but does not

reach the pressure desired

•

When pressing the trigger, the

pressure lowers considerably

•

The pressure is normal but the

product is not atomized

•

The atomization is imperfect

•

When releasing the trigger of the

gun, the equipment does not stop

(the motor runs slowly and the

piston rod keeps on going up and

down)

• On/Off switch disconnected;

• Lack of gasoline;

• Breakdown of motor electric control box;

• The line of material coming out of the

pump is already under pressure;

• The product is solidified inside the

pump;

• Suction filter clogged;

• Suction ilter too fine;

• Product output valve closed;

• The equipment sucks air;

• Lack of product;

• The equipment sucks air;

• The recirculating-safety valve is open;

• The gaskets of the pumping group are

worn;

• Suction or delivery valve dirty;

• Nozzle too big or worn;

• The product is too dense;

• The filter of the gun-butt is too fine;

• The nozzle is partially clogged;

• The product is too dense;

• The filter of the gun-butt is too fine;

• The nozzle is worn;

• The gaskets of the pumping group are

worn;

• Suction or delivery valve dirty;

• Recirculating-safety valve defective.

•

Ensure the On/Off switch is on the

“on” position and turn clockwise the

pressure control knob;

•

Add gasoline;

•

Verify and replace it, if necessary;

•

Open the drain valve to release

pressure in the circuit;

•

Open the drain valve to release

pressure in the circuit and stop the

machine. Disassemble the pumping

group and the pressure transmitter

and clean;

•

Clean or replace it;

•

Replace it with a larger-mesh filter

(

with very dense products, remove

the filter

);

•

Open the product output valve;

•

Check the suction pipe;

•

Add the product;

•

Check the suction pipe;

•

Close the recirculating-safety valve;

•

Replace the gaskets;

•

Disassemble the pumping group;

•

Replace it with a smaller one;

•

Dilute the product, if possible;

•

Replace it with a larger-mesh filter;

•

Clean or replace it;

•

Dilute the product, if possible;

•

Replace it with a larger-mesh filter;

•

Replace it;

•

Replace the gaskets;

•

Disassemble the pumping group and

clean;

•

Verify and replace it, if necessary.

Check the packing nut is tight in order to avoid

wastes but not excessively to prevent the piston

from seizing and the gaskets from wearing.

Oil ring