1P124-2306

5-7

Seed Meter Adjustment

IMPORTANT

The Clutch must be disengaged when Seed Shafts are

turned manually for Calibration.

IMPORTANT

All the Seed Meters MUST BE CLOSED! It may be

necessary to individually adjust Seed Meter Cups.

All Seed Meters must be set the same to ensure uniform

seeding. To check, set the Seed Rate Adjusting Nut to

0-A. The “A” on the Seed Rate Adjusting Nut is

positioned over the “0” (the nut covers half of the “0”) and

snug against the Bearing.

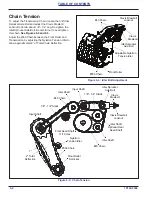

Figure 5-6: Front Seed Box Rate Adjuster

Figure 5-7: Rear Seed Box Rate Adjuster

All Seed Meters should be closed. Seed Meter Feed

Shutoff against Seed Meter Cup Star Washer in Seed

Meter Cup.

If not, there are three

adjustments to make as needed.

Figure 5-8: Seed Meter Feed Shutoff

IMPORTANT

Ensure that the Seed Shaft can turn freely without any

binding when the Seed Meters are open or closed

after servicing. Seed Box with Large Seed Meters you

may need to make adjustments to the Seed Meter

Supports at each Seed Meter Cup. See Figure 5-9.

Figure 5-9: Seed Meter Supports

1. 1/2-13 Locknuts on both ends of the Adjusting Screw

are used to adjust all Seed Meters the same amount.

To adjust Seed Meters to

be closed at “0A”, loosen 1/2-13 Locknuts and set

Adjusting Screw to “0A”. Slide Seed Shaft to close all

Seed Meters. Tighten 1/2-13 Locknuts against

Adjusting Screw.

2.

Front Seed Box:

Adjusting the LH and RH Seed

Shafts where they join changes Seed Meters on the

left Seed Box in comparison with Seed Meters on the

right Seed Box. Remove Seed Shaft Coupling that

clamps the left and right Seed Shafts together. Turn

RH Seed Shaft threading it in or out as needed to

equalize Seed Meters. Re-Install Seed Shaft

Coupling where the RH and LH Seed Shafts come

together.

DO NOT

Loosen or Adjust

1/2-13 Locknut

Seed Rate

Adjusting Nut

1-8 Nut

Adjusting

Screw

Seed Shaft

Bearing

DO NOT

Loosen or Adjust

1/2-13 Locknut

Seed

Shaft

Seed Rate

Adjusting Nut

Bearing

DO NOT

Loosen or Adjust

1/2-13 Locknut

1-8 Nut

Adjusting

Screw

DO NOT

Loosen or Adjust

1/2-13 Locknut

)HHG6KXWRႇ

Feed Roll

Seed Meter

Cup

Seed Meter Cup

Star Washer

Seed Meter

Support

Seed

Meter Cup

Flange Bolt

Содержание Brillion Turfmaker III Series

Страница 4: ......

Страница 14: ...1 6 1P124 2306 TABLE OF CONTENTS Figure 1 4 Decal Placement Hitch SL2 HitchDecals 1 9 1 9 3...

Страница 18: ...1 10 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...

Страница 45: ...1P124 2306 2 27 TABLE OF CONTENTS Table provided for general use NOTES...

Страница 49: ...1P124 2306 2 31 TABLE OF CONTENTS Table provided for general use NOTES...

Страница 57: ...1P124 2306 2 39 TABLE OF CONTENTS Table provided for general use NOTES...

Страница 74: ...3 14 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...

Страница 102: ...6 4 1P124 2306 TABLE OF CONTENTS Table provided for general use NOTES...