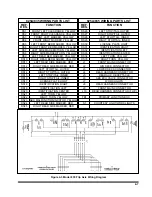

4-9 HUB AND DRUM MAINTENANCE

4-9.1

Clean and inspect the brake drums

whenever relining the brakes. To be suitable

for further service, the brake drum should

pass the following checks.

a.

The brake surface should be free of scoring,

excessive heat checks and cracks.

b.

The brake surface diameter should be within

the maximum diameter cast or stamped on

the drum.

c.

The mounting holes and pilot must be round

and true.

d.

The mounting surface must be clean and

flat.

WARNING

FAILURE TO REPLACE FAULTY

BRAKE DRUMS WILL RESULT IN AN

UNRELIABLE BRAKING SYSTEM, AND

MAY LEAD TO AN ACCIDENT.

4-9.2

It may be necessary to turn or resurface

the braking surface to remove small heat

checks or other surface defects resulting

from normal use.

a.

The maximum diameter cast into the back

plate portion of the brake drum is the maxi-

mum diameter or discard diameter to which

the brake drum may be turned or worn and

still be usable. If any portion of the brake sur-

face exceeds the maximum diameter it must

be discarded. The maximum is .120 over the

nominal new diameter unless stated other-

wise on the casting. The maximum diameter

cast into the brake drum supersedes all pub-

lished information.

b.

When resurfacing a drum, allow at least

0.040 inches under the maximum diameter for

additional wear.

WARNING

TURNING A BRAKE DRUM BEYOND

0.040 INCHES UNDER THE MAXIMUM

DIAMETER WILL RESULT IN A

WEAKER BRAKE DRUM AND MAY RE-

SULT IN AN ACCIDENT.

4-9.3

Replacement of the brake drum is re-

quired if any of the following conditions exist:

a.

The brake drum is cracked.

b.

The brake surface is heat checked, grooved

or worn beyond the rebore limit or the maxi-

mum diameter.

c.

The back plate is cracked.

d.

The bolt holes are elongated.

e.

The brake drum has been severely over-

heated.

f.

The brake drum is out-of-round.

CAUTION

REPLACE BRAKE DRUMS IN PAIRS

TO ACHIEVE THE SAME BRAKING

POWER ON BOTH WHEELS AND

MAINTAIN AN EVEN BRAKING LOAD

ON THE AXLE. FAILURE TO DO THIS

MAY SIGNIFICANTLY REDUCE THE

PERFORMANCE, SERVICE LIFE,

AND/OR SAFETY OF YOUR VEHICLE.

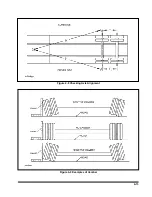

4-9.4

Replace the hub and drum as follows

(See Figure 4-14):

a.

Remove the brake drum

(See Figure 4-14)

.

It may be necessary to release the slack ad-

juster.

b.

Remove hub cap and catch lubricant in a

pan.

c.

Remove outer spindle nut, spindle locking

washer, inner spindle nut, and bearing. Re-

move hub from axle.

d.

Using an appropriate driver, remove inner

bearing cone, and seal.

e.

Using an appropriate driver, remove bearing

cups from hub.

f.

Check that the hub cavity is clean. If the hub

is to be reused, clean it thoroughly.

4-21

Содержание 825A

Страница 3: ...MODEL 825A 835 DETACHABLE TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Страница 8: ......

Страница 12: ......

Страница 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Страница 18: ...3 6 Figure 3 3 Hydraulic Controls...

Страница 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Страница 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Страница 34: ......

Страница 36: ...4 2 Figure 4 1 Lubrication Points...

Страница 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Страница 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Страница 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Страница 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Страница 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Страница 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Страница 69: ...NOTES 5 9...

Страница 70: ......