7

Features of the Blue Star IBD CB Series 22”/25”/30”

Cold Carbonation Capability

•

Water is pre-chilled in the cold plate before entering the

carbonator tank.

•

This allows it to absorb CO

2

more effectively inside the

tank.

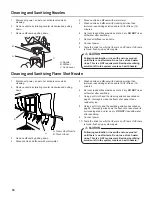

Three-Way Adjustable Back Blocks

•

Allows for flexibility between carbonated or plain water

drinks on the valves of your choice.

•

To set adjustable back blocks, turn the shut-off stem to the

desired location, refer to the image below:

A

B

C

E

A. Plain Water ON D. Water Closed

B. Carb Water ON E. Syrup Closed

C. Syrup ON

D

There is 100% flexibility on the 22”, 6 valve and the 30”

8 valve dispensers.

The 30”, 10 valve and the 25” 8 valve dispensers

have space restrictions, so the two center valves are

plumbed only for carbonated watered drinks and are

non-adjustable.

NOTE

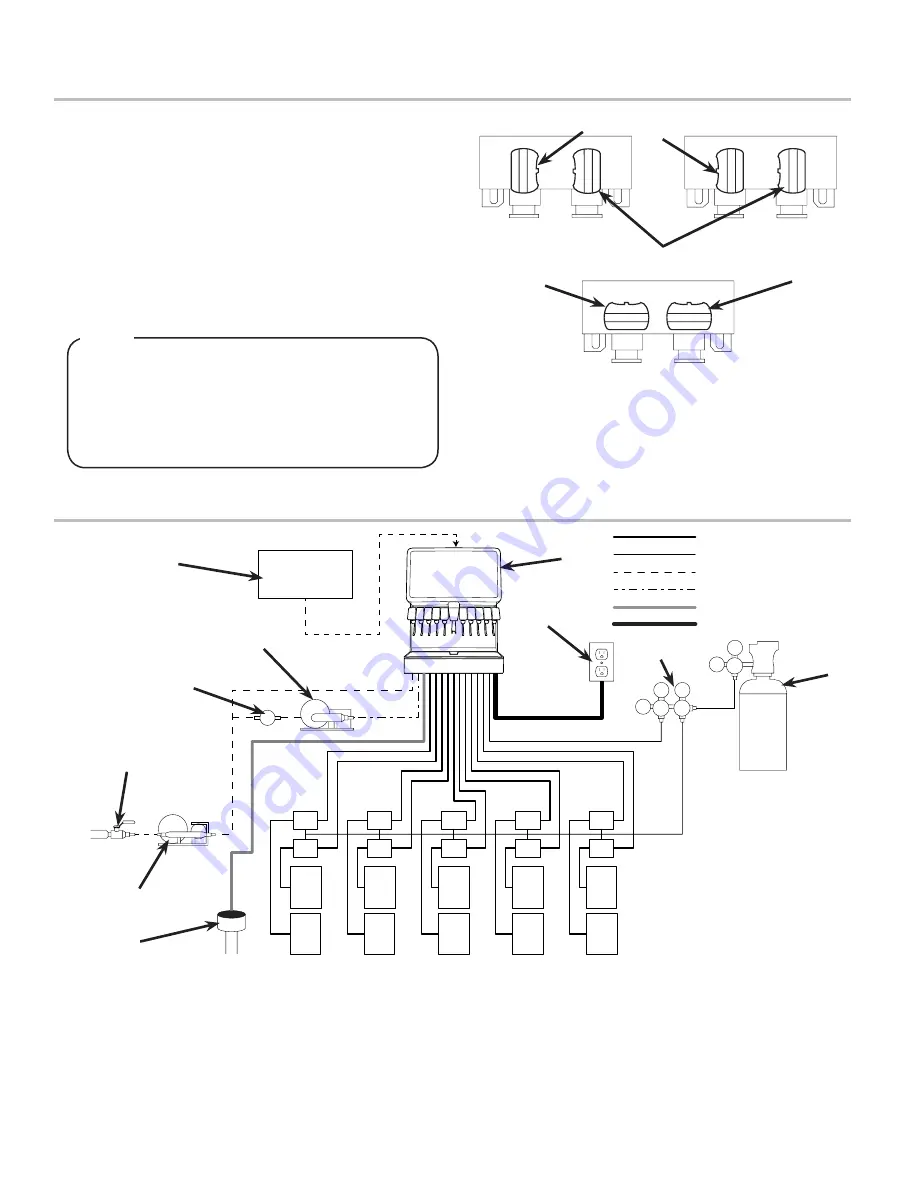

General System Overview - Remote Syrup Pumps

75

110

75

Syrup Line

CO

2

Line

Plain Water Line

Carb Water Line

Drain Line

Electrical

A. Water Source

B. Water Booster

C. Floor Drain

D. Water Regulator

E. Remote Pump

F. Syrup Pump

G. BIB Syrup Containers

H. Dispenser

I. Icemaker (Optional)

J. Electrical Outlet

K. CO

2

Regulator

L. CO

2

Source

A

B

C

D

E

F

F

F

F

F

F

G

G

G

G

G

G

G

G

G

G

F

F

F

F

I

H

L

J

K

Содержание Blue Star CB Series

Страница 25: ...25 Plumbing Diagram 22 Plumbing Diagram 25 Syrup Lines Not Shown Syrup Lines Not Shown...

Страница 26: ...26 Plumbing Diagram 30 8 Valve Plumbing Diagram 30 10 Valve Syrup Lines Not Shown Syrup Lines Not Shown...

Страница 28: ...Lancer Corp 800 729 1500 Technical Support Warranty 800 729 1550 custserv lancercorp com lancercorp com...