KYRA D 30 SI UNIT COND

A73022660

44

EN

A

Starting without pre-heater

B

Flame present

C

Normal operation

D

Adjustment stop (TA-TC)

t1

Pre-ventilation

time

TSA

Safety time

t3

Pre-ignition

time

t3n

Post-ignition

time

tw

Pre-heating

time

Output signals from the unit

Necessary input signals

Checks during operation

• Ignite the appliance as described in sec.2.3.

• Check that the fuel circuit and water systems are airtight.

• Check the ef

fi

ciency of the

fl

ue and air-fume ducts while the boiler is working.

• Check that the water is circulating properly between the boiler and the systems.

•

Check the proper ignition of the boiler by performing various tests, turning it on

andoff with the room thermostat or remote control.

• Check that the burner door and fume chamber are tight.

• Check that the burner works properly.

•

Analyse the combustion (with the boiler unit stable) and check that the content

of CO2 in the fumes is between 11% and 12%.

• Check the parameters are programmed correctly and perform any required cus-

tomization (compensation curve, power, temperatures, etc.).

4.3 Maintenance

Periodical check

To ensure correct operation of the unit over time, have quali

fi

ed personnel carry out

ayearly check, providing for the following:

• The control and safety devices must function correctly.

• The fume exhaust circuit must be perfectly ef

fi

cient.

•

Check there are no obstructions or dents in the fuel supply and return pipes.•-

Clean the

fi

lter of the fuel suction line.

• Measure the correct fuel consumption

• Clean the combustion head in the fuel outlet zone, on the swirl disc.

• Leave the burner running at full rate for approximately ten minutes, then analy-

sethe combustion, checking:

- All the elements speci

fi

ed in this manual are set correctly

- Temperatures of the fumes at the

fl

ue

- CO2 percentage content

• The air-fume end piece and ducts must be free of obstructions and leaks

•

The burner and exchanger must be clean and free of deposits. For possible

cleanng do not use chemical products or wire brushes.

• The gas and water systems must be airtight.

•

The water pressure in the cold water system must be approx. 1 bar; otherwise,

bringit to that value.•The circulating pump must not be blocked.

• The expansion tank must be

fi

lled.

• Check the magnesium anode and replace it if necessary.

The boiler casing, control panel and aesthetic parts can be cleaned with

a softand damp cloth, if necessary soaked in soapy water. Do not use

any abrasivedetergents and solvents.

Cleaning the boiler

1. Disconnect the power supply to the boiler.

2. Remove the upper panel

“A”

and open the burner door.

3. Unscrew the nuts

“B”.

4. Remove the cover from the smoke chamber

“E”.

5. 5. Remove the turbulators

"C"

.

6. Wipe the outlet of the fumes with a brush

“D”

and an aspirator.

7. Remove all residues from the combustion chamber.

8. Reassemble all removed components.

A

B

E

C

D

fi

g.32

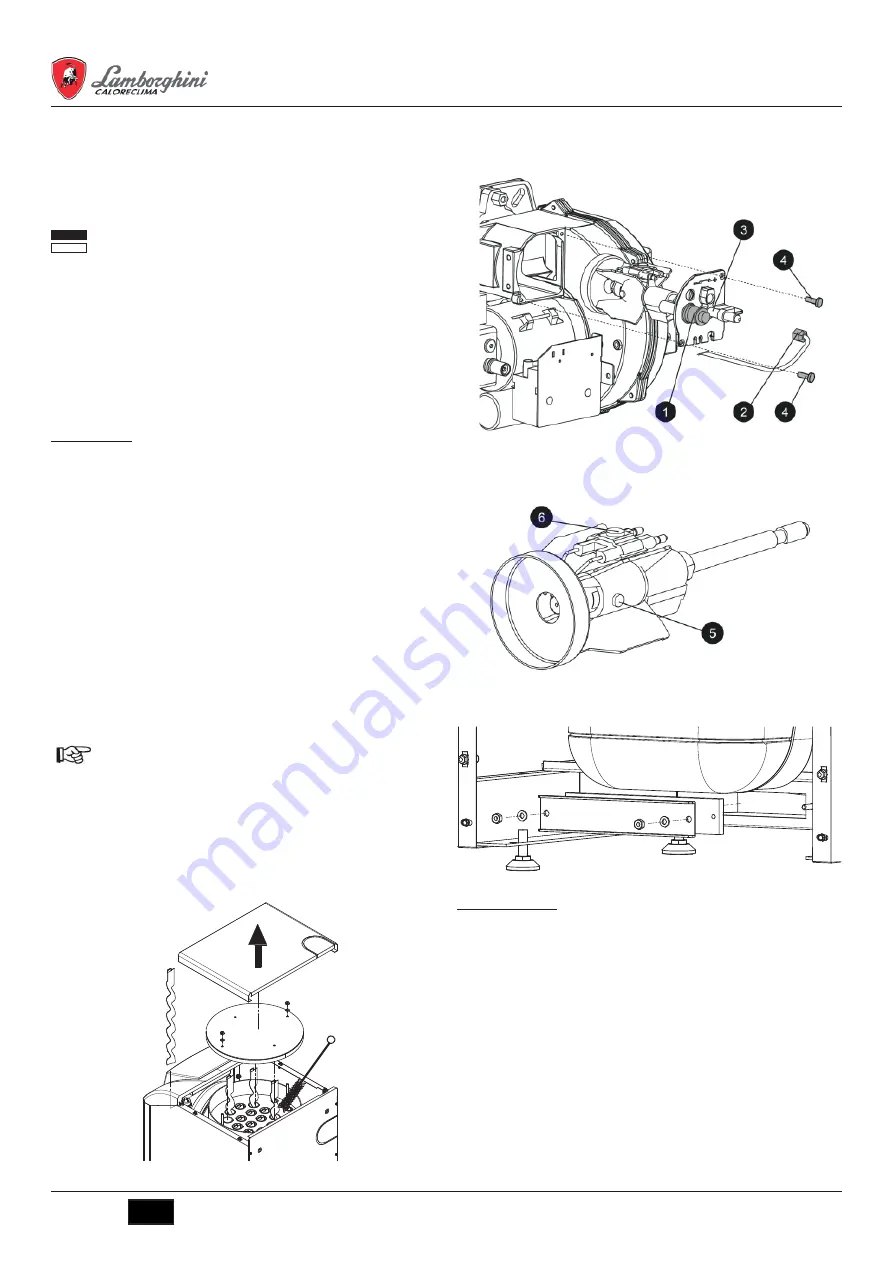

Accessing the electrode and nozzle

• Disconnect the transformer electrode cables and remove the photoresistance

1,

andt he union

2

connecting the oil pipe to line

3

of the nozzle. Loosen the screws

4

andpull out the nozzle-baf

fl

e-electrode

fl

ange assembly.

fi

g.33

•

Undo

the

screw

5

to remove the baf

fl

e and screw

6

to remove the electrodes.

Propercleaning of the nozzle is obtained by removing the

fi

lter and cleaning the

slots andspraying hole with petrol, rinsing it with fuel oil. When reassembling

everything, payattention to the correct positioning of the electrodes-baf

fl

e.

fi

g.34

Condensate tank

To access the condensate tank, open the lower cover (Fig. 35).

fi

g.35

4.4 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler

fault, the display will

fl

ash together with the fault symbol (9 -

fi

g.1) indicating the

faultcode.

There are faults the cause permanent shutdowns (marked with the letter

“A”

): to

restore operation, just press the

RESET

button (3 -

fi

g.1) for 1 second or use the

RE-

SET

on the remote timer control (optional) if installed; if the boiler does not restart, it

is necessary to eliminate the fault indicated in the operation LEDs.

Other faults cause temporary shutdowns (marked with the letter

“F”

) which are

automatically reset as soon as the value returns within the boiler’s normal working

range.