15

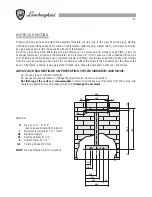

BOILER INSTALLATION

UNPACKING THE BOILER

1

Open the top of the carton and remove the

following parts:

Boiler tools and accessory pack

Document pack and wall template

Wall mounting template

Down-draft diverter

2

Break open the boiler carton with care.

Do not

cut the carton, open with a knife: you could

damage the jacket.

Make sure that the surface on which the carton is

resting is protected so the boiler is not scratched

or damaged during unpacking.

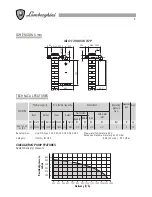

PREPARING THE WALL

1

Use the supplied template to decide on boiler

positioning.

The template is the same size as the boiler plus

the spaces which need to be maintained around

it.

Note

: When deciding on boiler position take into

account the flue terminal position.

2

Attach the template to the wall with adhesive tape

(make sure it is level) and mark the position of

the two holes used to fix the bracket to the wall,

the two holes for the upper part of the boiler and,

in the case of a rear-mounted fume outlet, the

flue hole.

If there is to be a side flue continue with the central

horizontal line of the flue along the wall towards

the side wall and then along the side wall for

160 mm. This is the position of the centre of the

flue hole.

3

Cut the 105 mm flue hole in the wall. Make sure

that it is horizontal. Drill the four fixing holes:

these must be suitable for the n. 9 plugs (supplied).

Fit the plugs.

4

Fix the assembly bracket to the wall with the two

supplied screws. Make sure that it is level and

fitted the right way round.

Template

Position of

105 mm

hole to be

prepared

for side

flue

160

Wall

bracket

Side

wall