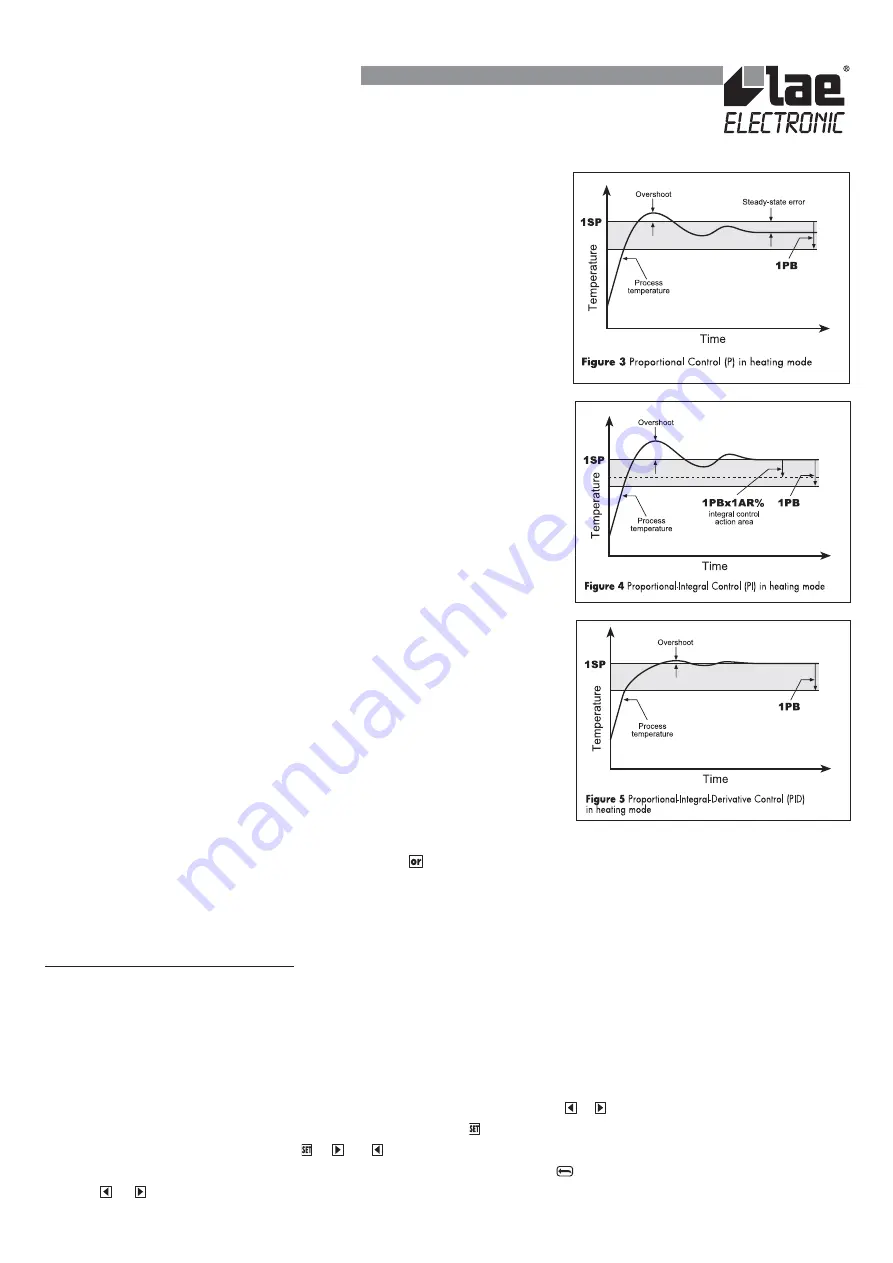

4.4.1. P

ROPORTIONAL CONTROL

. The temperature is controlled by varying the time

of activation of the output when the temperature is inside the proportional band

(

1PB

). The nearer the temperature to set point, the less time of activation. A small

proportional band increases the promptness of response of the system to

temperature variations, but tends to make it less stable. A purely proportional control

stabilises the temperature within the proportional band but does not cancel the

deviation from the set point.

4.4.2. P

ROPORTIONAL

-

INTEGRAL CONTROL

. The steady-state error is cancelled by

inserting an integral action into the control system. The integral action time,

1IT

,

determines the speed of cancellation of the error, but a high speed (

1IT

low) may

be the cause of overshoot and instability in the response. The integral part normally

acts within the proportional band, but this area of action may be reduced in terms

of percentage by lowering the integral action reset

1AR

. The response overshoot is

thus decreased. The integral control is cancelled when the temperature goes outside

the area of action of the integral part. With

1IT=0

the integral control is disabled.

4.4.3. P

ROPORTIONAL

-

INTEGRAL

-

DERIVATIVE CONTROL

.

Response overshoot in a

system controlled by a PI controller may be reduced by inserting a derivative action

in the control. The derivative action is greater the faster the temperature variation

within the time unit. A controller with a high derivative action (1

DT

high) is extremely

sensitive to small temperature variations and can make the system instable. With

1DT=0

the derivative control is disabled.

4.5. M

ALFUNCTIONING

.

Following a sensor malfunction,

appears on the display and the output is controlled according to the

value of the parameter

1PF

.

CAUTION:

when programming the hysteresis 1HY or the proportional band 1PB, it is advisable to consider the number of

switchovers that the relay will carry out and, if necessary, adapt the cycle time in order to limit the frequency of switchover.

5. AUTO-TUNING

5.1.

B

EFORE STARTING

. Before starting the auto-tuning procedure, ensure that the output has been set with PID control, the

proportional band has the sign corresponding to the required mode of operation (heating/cooling) and that the set point has been

fixed at the required value. The auto-tuning procedure is divided into two parts. In the first part, the operator has to characterise

the process to be controlled by fixing the cycle time. In the second, the controller acquires the responses of the system to certain

stresses for efficient adaptation of the control parameters.

5.2.

S

TARTING THE FUNCTION

. To access the auto-tuning function, keep the keys

+

pressed for 3 seconds. If the output is

in the PID mode (1Y=PID),

1CT

starts to blink on the display. Press

to confirm selection of the channel; the current parameter

value is displayed simultaneously. Using +

or , change the cycle time to characterise the dynamics of the process to be

controlled. In this first phase the auto-tuning function may be quit by pressing key

. The acquisition phase starts upon pressing

the keys

+

or after 30 seconds without touching the keyboard.

INSTRUCTIONS FOR INSTALLATION AND USE.