Lada Niva Manual - Maintenance

Page 20

luggage compartment. Place the car on a flat level ground and set the front wheels in the

position that corresponds to the straight-ahead motion.

To stabilise the position of the suspension units, exert pressure on them by pushing down

first the rear and then the front bumpers for 2-3 times, applying a force of about 400-500 N

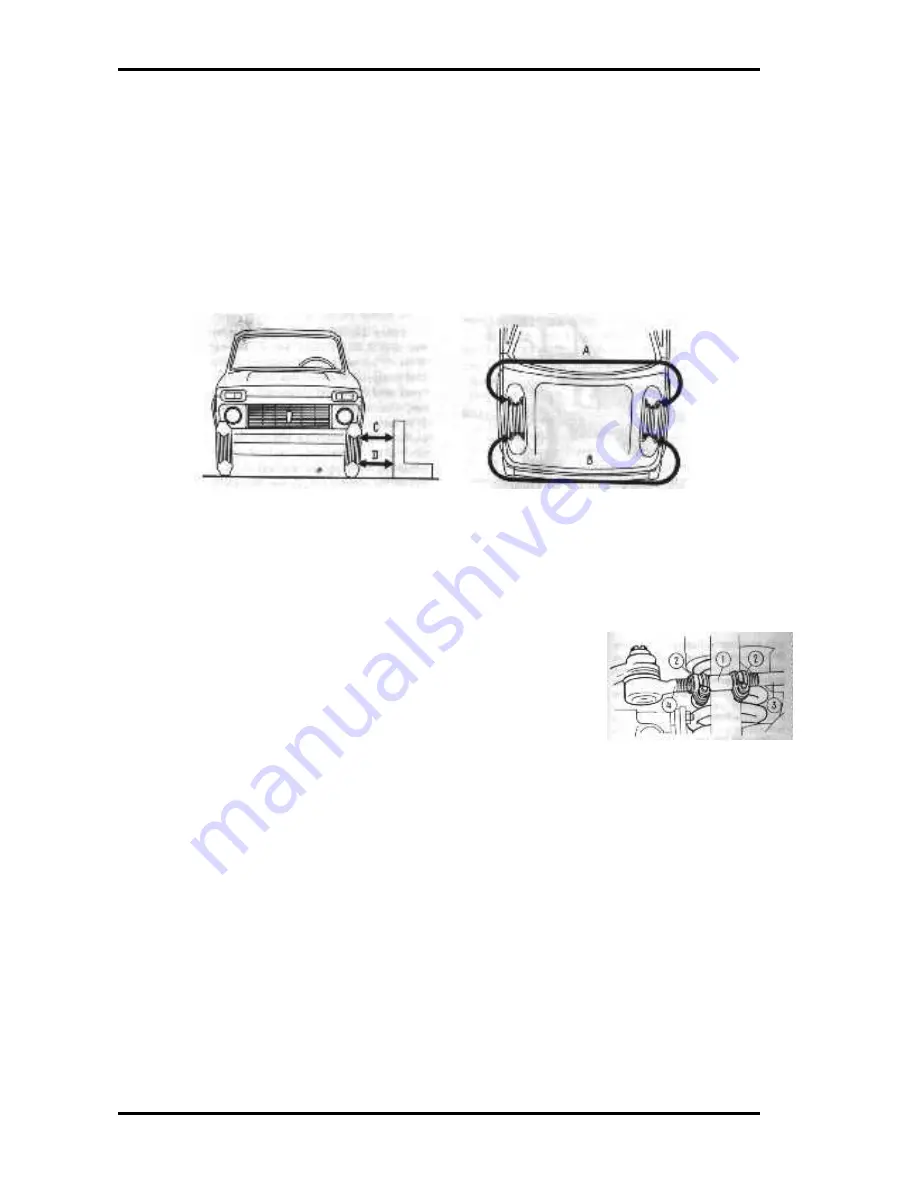

(40-50 kg). To determine wheel camber, measure distance C (Fig. 55) between the wheel rim

and the set square. Then roll the car to turn the wheels through 180", and measure distance D.

Camber is correct if distance D is 1-5 mm greater than distance C. Camber is adjusted by

changing the number of shims 20 (Fig. 51) between the upper wishbone shaft and the cross

member. Check and adjust toe-in only after checking and adjusting the wheel camber.

Fig 55. Checking front end alignment

To determine toe-in, measure distance A (Fig. 55) between the corresponding points on the

front wheel rims. Then roll the car to turn its wheels through 180" and measure distance D is

1-5 mm greater than distance C.

Camber is adjusted by changing the number of shims 20 (Fig 51) between the upper

wishbone shaft and the cross member.

Check and adjust toe-in, measure distance A (Fig 55) between the

corresponding points on the front wheel rims. Then roll the car to

turn its’ wheels through 180 degrees and measure distance B. Toe-in is

correct, if the first dimension is 2-4 mm greater than the second one.

Toe-in is adjusted by changing the length of side steering rods 3 (Fig.

56). For this purpose loosen clamps 2 and turn adjusting sleeves 1

through the same number of revolutions in the opposite directions,

thus screwing the sleeves on or off and changing the length of the side

steering rods. Adjustment over, tighten clamps 2 to a torque of 19 N Æ

m (1.9 kg Æ

m) so that

their slots face down and their ends, after tightening, do not touch each other.

Camber and toe-in can be also checked and adjusted, though less accurately, with the car

unloaded. In this case wheel camber D-C should be from -1 to +3 mm, and toe-in A-B should

be 4~1 mm.

BRAKES

Brake Hydraulic System

The brake system of the car is given in Pig. 57. Prior to servicing the brake system, clean each

brake of dirt, wash it with warm water and dry with compressed air.

Never use gasoline, diesel fuel, trichloroethylene or other mineral solvents for the purpose

since they attack the cups and seals of the hydraulic cylinders.

The surfaces of the brake linings should be clean, with no traces of dirt or lubricant. Soiled

linings should be cleaned with a wire brush and washed with white spirit. If the pads or linings

Fig 56. Adjusting length of side

steering rods

. 1- sleeve, 2- clamps, 3

side steering rod, 4- steering rod end.

Содержание Niva

Страница 1: ......

Страница 31: ...Lada Niva Manual Maintenance Page 30 Headlight upper beam warning lamp ...