SETUP

1. Using the set screws provided, affix a Core Holder onto the Upper and

Lower Spindle Motors.

2. Rotate each Core Holder by hand to ensure that there is no interference with

the Drive Unit.

3. Set the unit in place where you want it. CAUTION: Avoid accidents. The

TWIN-CAT-3 weighs approximately 35-pounds (16-kg), so choose only a

sturdy surface on which to place it. The TWIN-CAT-3 is bi-directional. Either

Spindle can wind labels in either direction.

4. Verify that the “DIRECTION” Switch on the TWIN-CAT-3 Control Panel is in

the “OFF” position.

5. Plug the Power Plug at the end of the wire on the Power Supply Module into

the TWIN-CAT-3 Power Input Jack. Plug the Power Supply Line Cord into

an appropriate AC power outlet. The unit is now ready for use.

LABEL REWINDING

1. Place the “DIRECTION” Switches on the TWIN-CAT-3 Control Panel in the

center “OFF” position.

2. Slide an empty label core over the desired Core Holder until the core is

against the inner Flange Plate.

3. Feed the label web from the printer or Slitter and secure it to the take-up roll

core with tape. Rotate the take-up reel a couple of turns.

4. Check that the TWIN-CAT-3 Unit is square with the printer or Slitter.

5. Rotate the “TORQUE” Control Knob to the minimum position (fully counter-

clockwise).

6. Place each TWIN-CAT-3 “DIRECTION” Switch in the position desired to run

left or right.

7. Start the printer and adjust the “TORQUE” Control Knob for the desired

tension. The Upper and Lower Spindles are controlled independently and

together can be set to control the rewind / unwind tension and speed.

8. Use the minimum “TORQUE” setting needed to rewind labels properly.

Excessive torque might pull the labels too hard and cause the printer to lose

registration.

WIND-IN / WIND-OUT

You can use the Dual Spindles to reverse the direction the labels are facing.

You can also rewind the labels so that they are in the original (serialized

order) they came out of the printer. An optional Adjustable Paper Guide

(APG-CAT) can be fitted to help guide the outer edge of the lower label roll

as it rewinds. Quick-Chucks are provided with Outer Label Flanges.

WARNING

This product is for indoor use only.

Not for use in wet locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services.

LABEL SLITTING

The TWIN-CAT-3 Label Rewinder (with “Quick-Chucks”) is ideal as part of a

setup to slit labels. If small labels are printed several “up” (across) and

then slit to their desired width, you realize much greater effective print

speed and print head and ribbon efficiency. LABELMATE’s Model S-100

uses the power of the TWIN-CAT-3 to pull the labels through the slitting

blades. Slitting can take place either “in-line” with one or two blades

directly after exiting the printer, or “off-line” for greater efficiency where a

roll of printed labels is unwound from a LABELMATE Label Unwinder.

Three or more blades can be used in an “off-line” setup.

SLITTER SETUP

1. Position the TWIN-CAT-3 near the exit path of the Slitter Unit.

2. Verify that the “DIRECTION” Switch on the TWIN-CAT-3 Control Panel is

in the “OFF” position.

3. Thread the label web to be slit through the Slitter to begin the cuts.

4. Tape alternate slit webs alternately onto the lower and upper “Quick-

Chuck” Core Chucks and tape them onto the rewind cores you have

placed on the upper and lower Spindles. See the Slitter User Manual for

full instructions.

5. Rotate the “TORQUE” control to its minimum (fully CCW) position.

6. Place the “DIRECTION” Switch in the desired position for label transport.

7. Observe the movement of the labels through the Slitter and increase the

“TORQUE” setting as required.

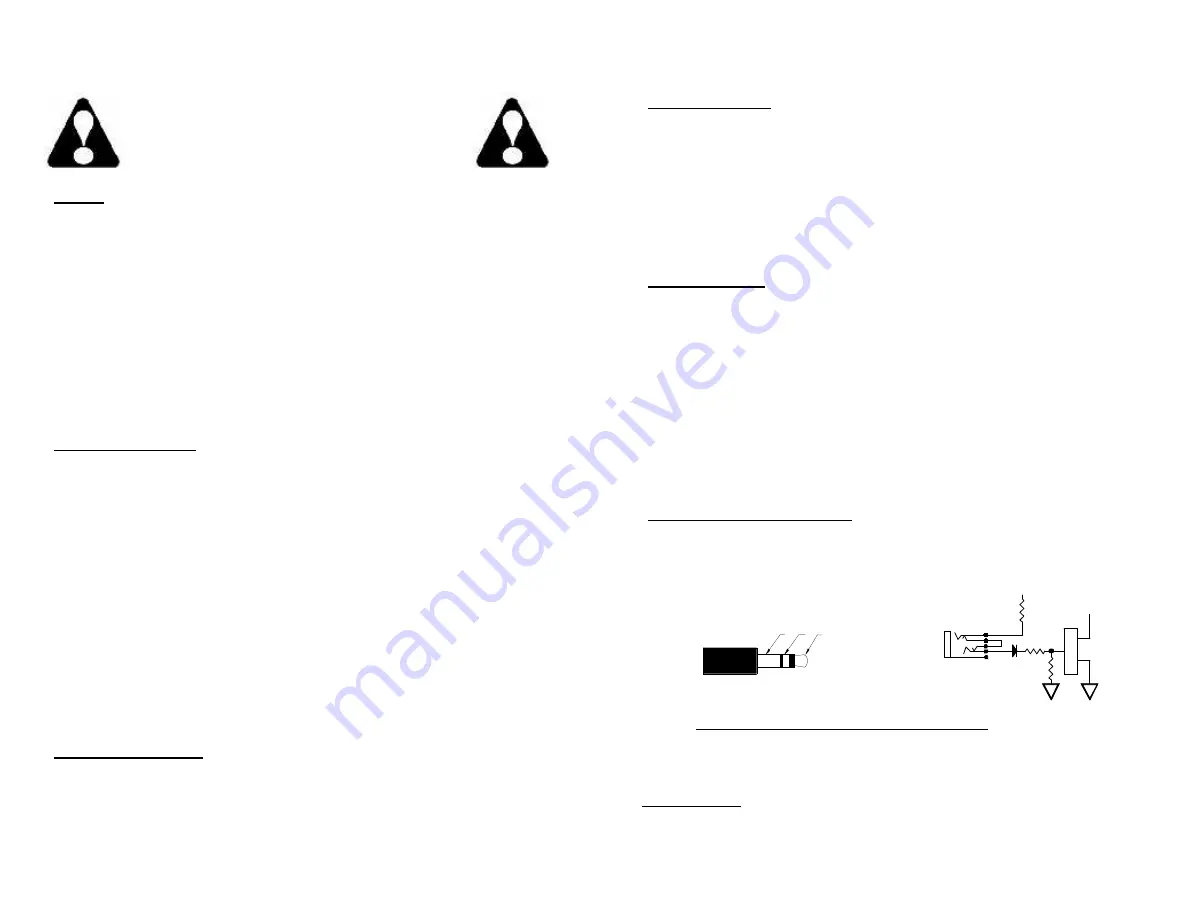

EXTERNAL HALT CONTROL (Use is optional)

The External Halt Control jack is for use with external devices capable of

using an open circuit halt command. A 3.5mm control cable is required

(not included).

3.5mm Dual Circuit Plug

Contact CLOSED=RUN

Contact OPEN=HALT

Pin 1 - No connection (NOT USED)

Pin 2 - Normally Closed (NC) contact

Pin 3 - Normally Closed (NC) contact return

MAINTENANCE

Your TWIN-CAT-3 Dual Spindle Rewinder/Unwinder requires no

maintenance.

SETUP

1. Using the set screws provided, affix a Core Holder onto the Upper and

Lower Spindle Motors.

2. Rotate each Core Holder by hand to ensure that there is no interference with

the Drive Unit.

3. Set the unit in place where you want it. CAUTION: Avoid accidents. The

TWIN-CAT-3 weighs approximately 35-pounds (16-kg), so choose only a

sturdy surface on which to place it. The TWIN-CAT-3 is bi-directional. Either

Spindle can wind labels in either direction.

4. Verify that the “DIRECTION” Switch on the TWIN-CAT-3 Control Panel is in

the “OFF” position.

5. Plug the Power Plug at the end of the wire on the Power Supply Module into

the TWIN-CAT-3 Power Input Jack. Plug the Power Supply Line Cord into

an appropriate AC power outlet. The unit is now ready for use.

LABEL REWINDING

1. Place the “DIRECTION” Switches on the TWIN-CAT-3 Control Panel in the

center “OFF” position.

2. Slide an empty label core over the desired Core Holder until the core is

against the inner Flange Plate.

3. Feed the label web from the printer or Slitter and secure it to the take-up roll

core with tape. Rotate the take-up reel a couple of turns.

4. Check that the TWIN-CAT-3 Unit is square with the printer or Slitter.

5. Rotate the “TORQUE” Control Knob to the minimum position (fully counter-

clockwise).

6. Place each TWIN-CAT-3 “DIRECTION” Switch in the position desired to run

left or right.

7. Start the printer and adjust the “TORQUE” Control Knob for the desired

tension. The Upper and Lower Spindles are controlled independently and

together can be set to control the rewind / unwind tension and speed.

8. Use the minimum “TORQUE” setting needed to rewind labels properly.

Excessive torque might pull the labels too hard and cause the printer to lose

registration.

WIND-IN / WIND-OUT

You can use the Dual Spindles to reverse the direction the labels are facing.

You can also rewind the labels so that they are in the original (serialized

order) they came out of the printer. An optional Adjustable Paper Guide

(APG-CAT) can be fitted to help guide the outer edge of the lower label roll

as it rewinds. Quick-Chucks are provided with Outer Label Flanges.

WARNING

This product is for indoor use only.

Not for use in wet locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services.

LABEL SLITTING

The TWIN-CAT-3 Label Rewinder (with “Quick-Chucks”) is ideal as part of a

setup to slit labels. If small labels are printed several “up” (across) and

then slit to their desired width, you realize much greater effective print

speed and print head and ribbon efficiency. LABELMATE’s Model S-100

uses the power of the TWIN-CAT-3 to pull the labels through the slitting

blades. Slitting can take place either “in-line” with one or two blades

directly after exiting the printer, or “off-line” for greater efficiency where a

roll of printed labels is unwound from a LABELMATE Label Unwinder.

Three or more blades can be used in an “off-line” setup.

SLITTER SETUP

1. Position the TWIN-CAT-3 near the exit path of the Slitter Unit.

2. Verify that the “DIRECTION” Switch on the TWIN-CAT-3 Control Panel is

in the “OFF” position.

3. Thread the label web to be slit through the Slitter to begin the cuts.

4. Tape alternate slit webs alternately onto the lower and upper “Quick-

Chuck” Core Chucks and tape them onto the rewind cores you have

placed on the upper and lower Spindles. See the Slitter User Manual for

full instructions.

5. Rotate the “TORQUE” control to its minimum (fully CCW) position.

6. Place the “DIRECTION” Switch in the desired position for label transport.

7. Observe the movement of the labels through the Slitter and increase the

“TORQUE” setting as required.

EXTERNAL HALT CONTROL (Use is optional)

The External Halt Control jack is for use with external devices capable of

using an open circuit halt command. A 3.5mm control cable is required

(not included).

3.5mm Dual Circuit Plug

Contact CLOSED=RUN

Contact OPEN=HALT

Pin 1 - No connection (NOT USED)

Pin 2 - Normally Closed (NC) contact

Pin 3 - Normally Closed (NC) contact return

MAINTENANCE

Your TWIN-CAT-3 Dual Spindle Rewinder/Unwinder requires no

maintenance.

10K

12V

1K

D

S

G

10K

"EXT. HALT CONT."

3.5 mm Jack

Dual Circuit

2 3

1