Page 4

LAARS HEATING SYSTEMS

SECTION 2.

Installation Instructions

2A. General Information

Install the Mighty Max HH boiler in accordance

with the procedures in this manual (or the Laars

warranty may be voided), local codes, and ordinances.

In the absence of such codes, install the heaters in

accordance with the latest edition of the National Fuel

Gas Code, ANSI Z223.1/National Fire Protection

Association (NFPA) 54. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2 and

local codes. The authority having jurisdiction may

require the installation be in accordance with the

American Society of Mechanical Engineers (ASME)

Safety Codes for Controls and Safety Devices for

Automatically Fired Heaters, CSD-1, and in Canada,

Canadian Gas Association (CGA) 3.3. Any changes to

the boiler, its gas controls, gas orifices or wiring may

void the warranty. If field conditions require change,

consult the factory.

The Mighty Max HH boiler is designed-certified

for installation on a combustible floor. Do not install

the boiler directly on carpeting.

2B. Boiler Placement

Clearance From

Indoor

Outdoor

Combustibles

Inches mm

Inches mm

Top

18

457

Unobstructed

Water Conn. Side

12

305

12

305

Opposite Side

6

152

6

152

Front

Alcove

Unobstructed

Rear

6

152

6

152

Vent

*6

*

152

—

Flooring

Combustible

Combustible

Service clearance = 24 in. (610mm) at front of boiler.

*1 in. (25mm) if double wall vent is used.

Table 2. Minimum Boiler Clearances

from Combustible Surfaces.

Locate the boiler to provide adequate clearances

on all sides for maintenance and inspection. There

must also be minimum distances maintained from

combustible surfaces (See Table 2).

The boiler must be isolated or otherwise

protected from any source of corrosive chemical

fumes, such as trichlorethylene, perchlorethylene,

chlorine, etc. Install the boiler so that the gas ignition

system components are protected from water

(drippings, spraying, rain, etc.) during operation and

service.

2C. Installation of Outdoor Boilers

Caution

Outdoor installations are not recommended in

areas where the danger of snow blockage

exists.

1.

Locate the boiler to provide at least the

minimum clearances as listed in Section 2B,

“Boiler Placement.” HH boilers require an

outdoor terminal kit when installed outdoors (see

Section 6, Parts List).

2.

Do not locate the boiler in an enclosure or

through-wall recess. Avoid locations where wind

deflection off structures might cause down-draft.

When such wind conditions are possible, locate

the boiler at least 3 feet (.9m) from structures.

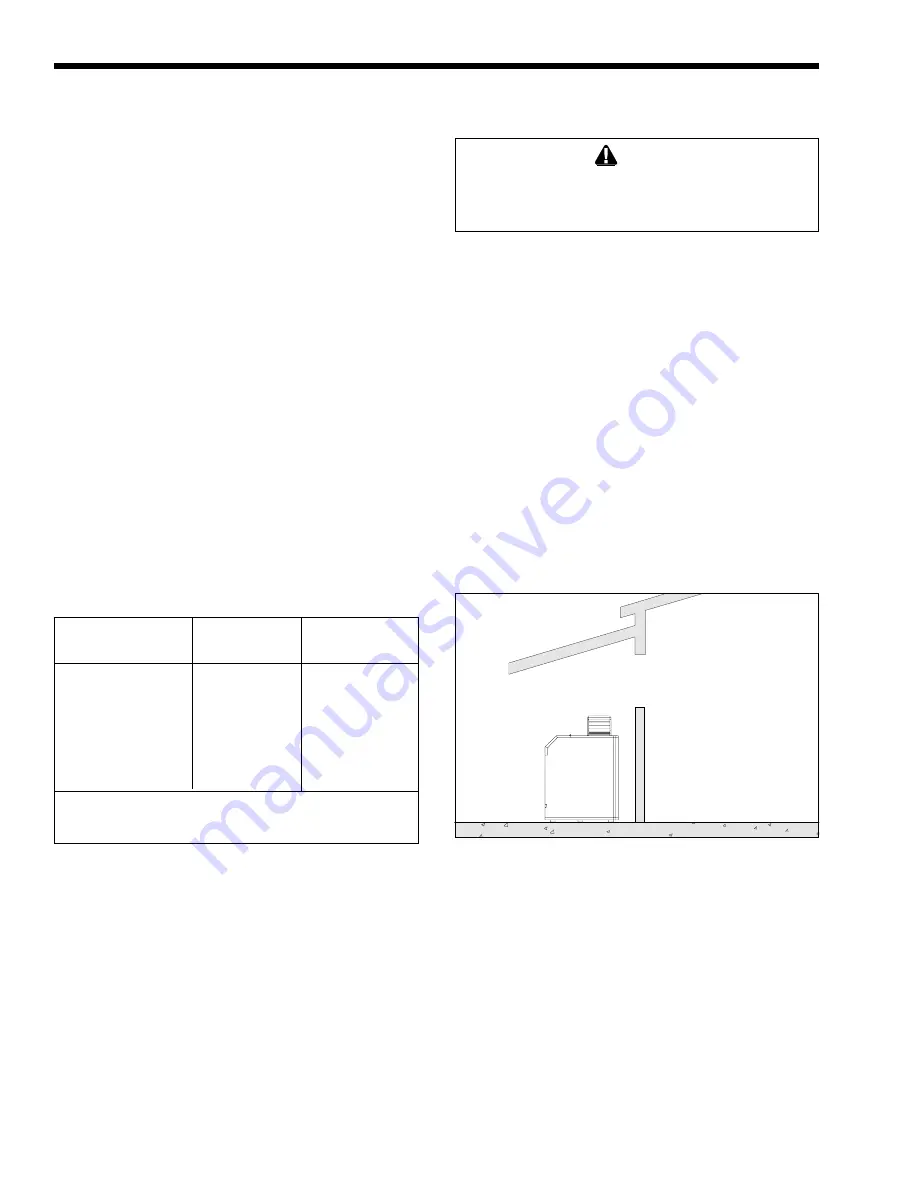

3.

Never install the boiler under any kind of roof

overhang. Do not locate the boiler below or

adjacent to any doors, windows, louvers, grills,

etc. which communicate in any way with an

inhabited area of a building, even though such

communication might be through another

structure such as a garage or utility room (see

Figure 2).

2D. Freeze Protection

Boiler installations are not recommended in

areas where the danger of freezing exists unless

proper precautions are made for freeze protection.

Maintaining a mixture of 50% water and 50%

properly inhibited HVAC glycol is the preferred

method of freeze protection for hydronic systems. (Do

not use automotive antifreeze.) This mixture will

protect the boiler to temperatures of about -35°F

(-37°C). To get the desired temperature rise across the

boiler when this mixture is used, increase the water

flow recommendation by 15%. Increase the head loss

requirement by 20%. Note: If your application does

WRONG

WINDOW

OR GRILL

INDOOR

ROOM

Figure 2. Incorrect Installation of Boiler.