LAARS Heating Systems

Page 8

commencing within 12” (300 mm) of the top and

one commencing within 12” (300 mm) of the

bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts,

with the outdoors or spaces that freely communicate

with the outdoors. when directly communicating

with the outdoors, or when communicating to the

outdoors through vertical ducts, each opening shall

have a minimum free area of 1 square inch per

4000 Btu/hr (550 square mm/kw) of total input

rating of all equipment in the enclosure. when

communicating to the outdoors through horizontal

ducts, each opening shall have a minimum free

area of not less than 1 square inch per 2000 Btu/

hr (1100 square mm/kw) of total input rating of all

equipment in the enclosure.

Method 2

: One permanent opening, commencing

within 12” (300 mm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall

communicate through a vertical or horizontal duct

to the outdoors or spaces that directly communicate

Section 3

VentInG anD ComBUStIon aIr

3.1

Combustion air

MagnaTherm boilers and water heaters must have

provisions for combustion and ventilation air in

accordance with the applicable requirements for

combustion Air Supply and Ventilation in the

National Fuel Gas Code, ANSI Z223 1; or in Canada,

the natural Gas and Propane installation code, cSA

B149.1. All applicable provisions of local building

codes must also be adhered to.

A MagnaTherm can take combustion air from the

space in which it is installed, or the combustion

air can be ducted directly to the unit. Ventilation

air must be provided in either case.

3.1.1

Combustion air from room

in the United States, the most common requirements

specify that the space shall communicate with the

outdoors in accordance with Method 1 or 2. (See the

following descriptions.) where ducts are used, they

shall be of the same cross-sectional area as the free

area of the openings to which they connect.

Method 1

: Two permanent openings, one

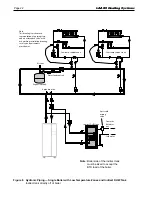

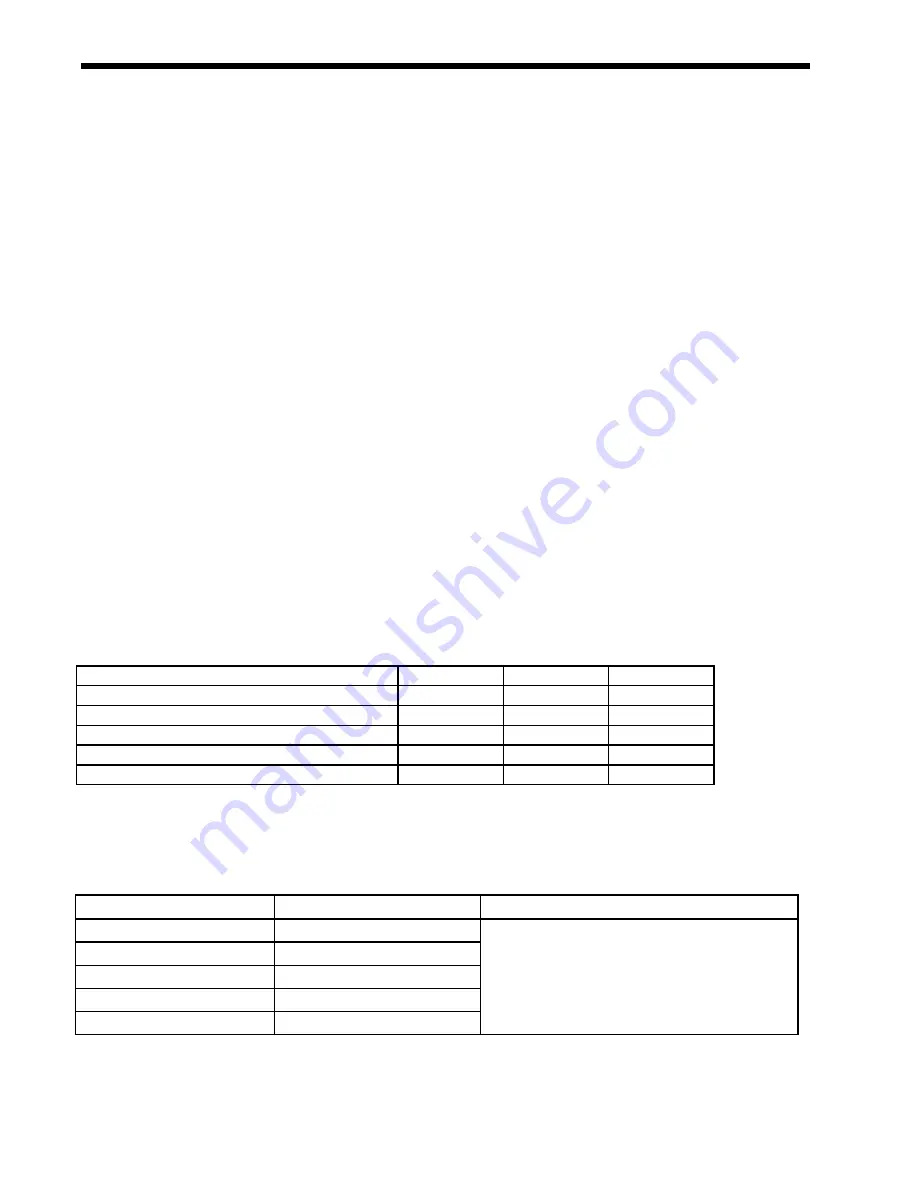

table 3. Ducted air accessories

(Place in section 3.1)

Model 2000

Model 3000

Model 4000

Screen for horizontal galvanized air pipe

D2012101

D2012102

D2012103

Screen for horizontal PVC air pipe

CA012001

CA012002

CA012003

Screen for horizontal polypropylene air pipe

CA012201

CA012202

CA012203

Screen for vertical galvanized air pipe

D2012201

D2012202

D2012203

Screen for vertical PVC air pipe

CA012401

CA012402

CA012403

Screen for vertical polypropylene air pipe

CA012601

CA012602

CA012603

Table 3a - Ducted Air Accessories

(Place in section 3.2)

Model 2000

Model 3000

Model 4000

Horizontal vent terminal for stainless steel

D2012001

D2012002

D2012003

Screen for horizontal CPVC vent

CA012101

CA012102

CA012103

Screen for vertical stainless steel vent

D2012301

D2012302

D2012303

Screen for vertical CPVC vent

CA012501

CA012502

CA012503

Table 3* - Vent Accessories

(Place in section 3.5)

Model 2000

Model 3000

Model 4000

Air intake screen for unit placed outdoors

CA011901

CA011902

CA0011903

Vent terminal for unit placed outdoors

CA011801

CA011802

CA011803

Table 3** - Air & Vent Accessories for Units Placed Outdoors

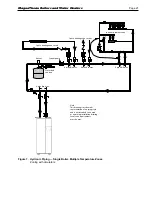

table 4. required Combustion air Pipe material

Material

United States

Canada

ABS

ANSI/ASTM D1527

The air pipe material must be chosen based upon

the intended application of the boiler, and must

be installed according to the vent manufacturer’s

installation instructions.

PVC, sch. 40

ANSI/ASTM D1785 or D2665

CPVC, sch. 40

ANSI/ASTM F441

Single wall galv. steel

26 gauge

Polypropylene

ULC S636 Class 2C