Inspection and preventive maintenance

Rigging part inspection

About this task

The term "rigging part" comprises:

• lifting accessories such as clamps and shackles

• rigging accessories such as rigging frames, rigging interfaces, and brackets

• fasteners used for assembling two products together such as ball-locking pins, rigging axes, and safety pins

• rigging plates mounted on enclosures and their rigging screws

• screens mounted on enclosures

This inspection procedure covers only L-Acoustics products. To inspect other products that are part of the lifting chain,

refer to the manufacturer's instructions.

Prerequisite

Perform the inspection in a well-lit environment.

Procedure

1.

Check that the rigging part is present.

2.

Check for:

• corrosion

• wear and cracks

• bends and dents

• holes

• missing safety cues

• missing identication labels

• missing or loose fasteners

Replacing screws

If a screw is loose, remove and replace it.

Always use the new screws provided in the repair kit.

If no new screw is available, add blue threadlocker before reusing the screw.

Do not apply more than the indicated torque.

3.

Check the geometry of the part to identify critical deformations.

What to do next

If a problem is detected, perform the authorized maintenance operations or contact your L-Acoustics representative.

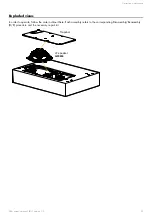

Mechanical system overview

Critical parts of the lifting chains are highlighted.

The

indicates a visual inspection.

(p.16) on critical parts.

Replacing screws

If a screw is loose, remove and replace it.

Always use the new screws provided in the repair kit.

If no new screw is available, add blue threadlocker before reusing the screw.

Do not apply more than the indicated torque.

16

SB6i owner's manual (EN) version 1.0

Содержание SB6i

Страница 1: ...SB6i owner s manual EN ...