Section 2: Operating Procedures

Table of Contents

4/9/19

AP-SA35 Hydraulic Post Hole Digger 317-093MK

15

•

Always shut power machine down following the “Shutdown

Procedure” provided in this manual before leaving the

operator’s seat.

•

Do not travel across inclines where equipment could slip or

roll-over. Consult your power machine Operator’s Manual

for acceptable inclines they are capable of crossing.

•

Backup alarm must be in good working order to warn

others. Use a backup camera or rear-view mirror that is in

good condition to help see undesirable situations behind the

unit. Drive at a slower speed to compensate for blind spots.

•

Never carry riders on the implement or power machine.

Riders can obstruct the operator’s view, interfere with

control of the equipment, be pinched by moving

components, become entangled in rotating components, be

struck by objects, be thrown or fall from the equipment, etc.

•

Hydraulic fluid under high pressure can penetrate the skin

and/or eyes causing a serious injury. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. Use a piece of cardboard or wood rather than

hands when searching for leaks. A doctor familiar with this

type of injury must treat the injury within a few hours or

gangrene may result. DO NOT DELAY.

•

Check hitch fit-up frequently. An improper fit-up can cause

the attachment to come loose from the loader hitch plate

and fall.

•

Operate only power machines equipped with a certified

Roll-Over Protective Structure (ROPS) and seat belt.

Fasten seat belt snugly and securely to help protect against

serious injury or death from machine overturn.

•

Always travel with adequate clearance between ground and

auger. Hitting an object while traveling can damage

equipment and cause operator to lose control.

•

Always travel with attachment lowered to reduce the

chances of tip over due to high center of gravity.

•

Do not install a bolt that is longer than what was originally

supplied with the auger. Protruding hardware is more likely

to entangle a bystander by catching on loose clothing.

•

This attachment has a 3500 psi maximum hydraulic

pressure rating. Make sure your powered machine’s

hydraulic pressure to this attachment does not exceed 3500

psi. Exceeding this rating can result in equipment damage,

serious injury, or death.

•

Do not use attachment to lift, carry, push or tow other

equipment and objects. It is not properly designed or

guarded for this use. The operator could lose control and

cause a tipping hazard.

•

Never adjust tractor pressure relief valve for a pressure

rating higher than what is recommended by the tractor

manufacture.

•

Protect freshly dug holes immediately after digging by

filling it with a post, covering the hole with a cover capable

of supporting a person, or place a physical boundary

around the hole to stop entry into the area.

•

Do not use post hole digger to wrap wire or any other items.

Doing so can result in bodily injury and/or damage to the

equipment.

•

Never work near utilities such as gas lines, electrical lines,

or other hazards that can cause serious injury or death from

electrocution, explosion, or fire.

•

Never make contact with underground utilities such as

electrical power lines, gas lines, phone lines, etc. They can

cause serious injury or death from electrocution, explosion,

or fire. If in doubt, call 811 (USA) before digging so that

they can mark the location of underground services in the

area. For contact information, see Dig Safe in the

“Important Safety Information” starting on page 1.

•

Avoid exposure to dust containing crystalline silica

particles. This dust can cause serious injury to the lungs

(silicosis). Because crystalline silica is a basic component

of sand and granite, many activities at construction sites

produce dust containing crystalline silica. Trenching,

sawing and boring of material containing crystalline silica

can produce dust containing crystalline silica.

CAUTION

!

To avoid minor or moderate injury:

Auger tip gets hot after digging. Allow time for the tip to cool

before touching or servicing the tip.

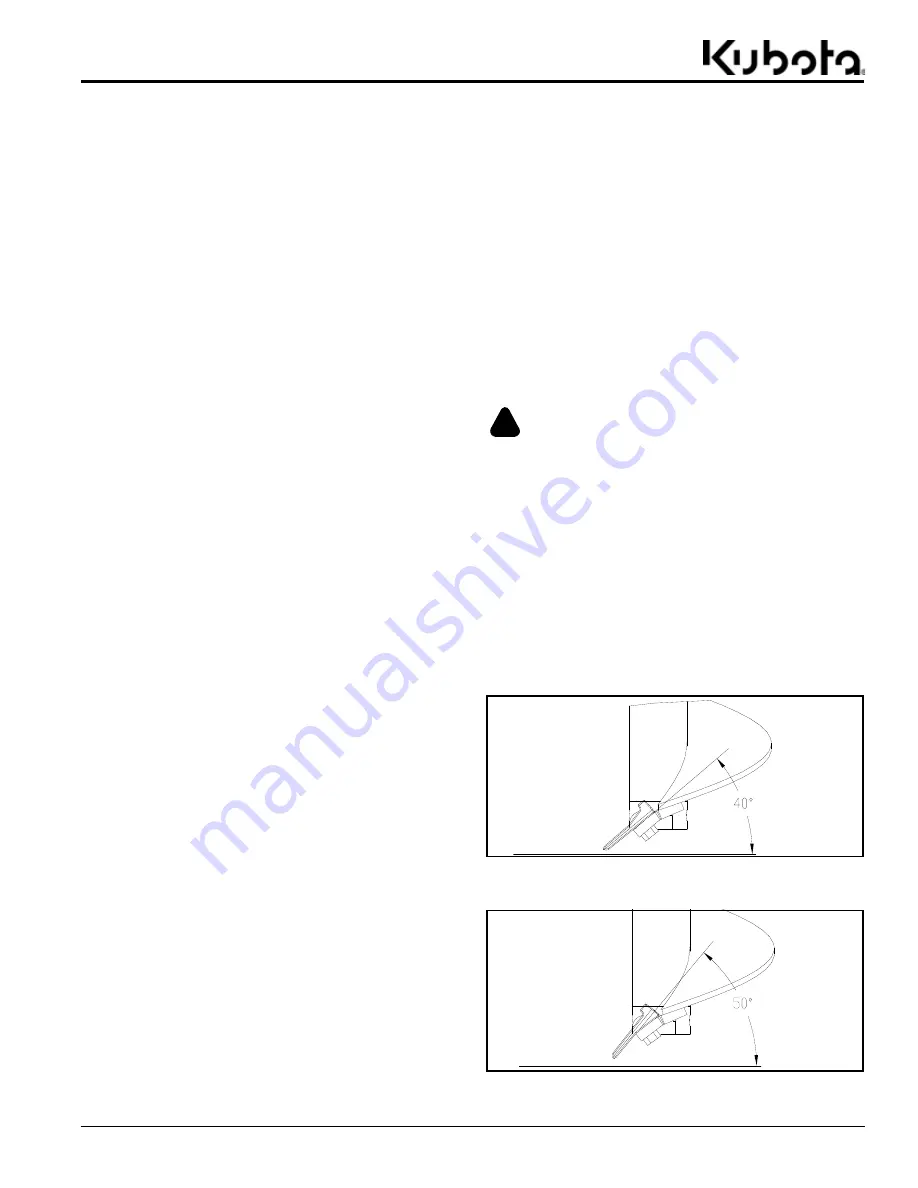

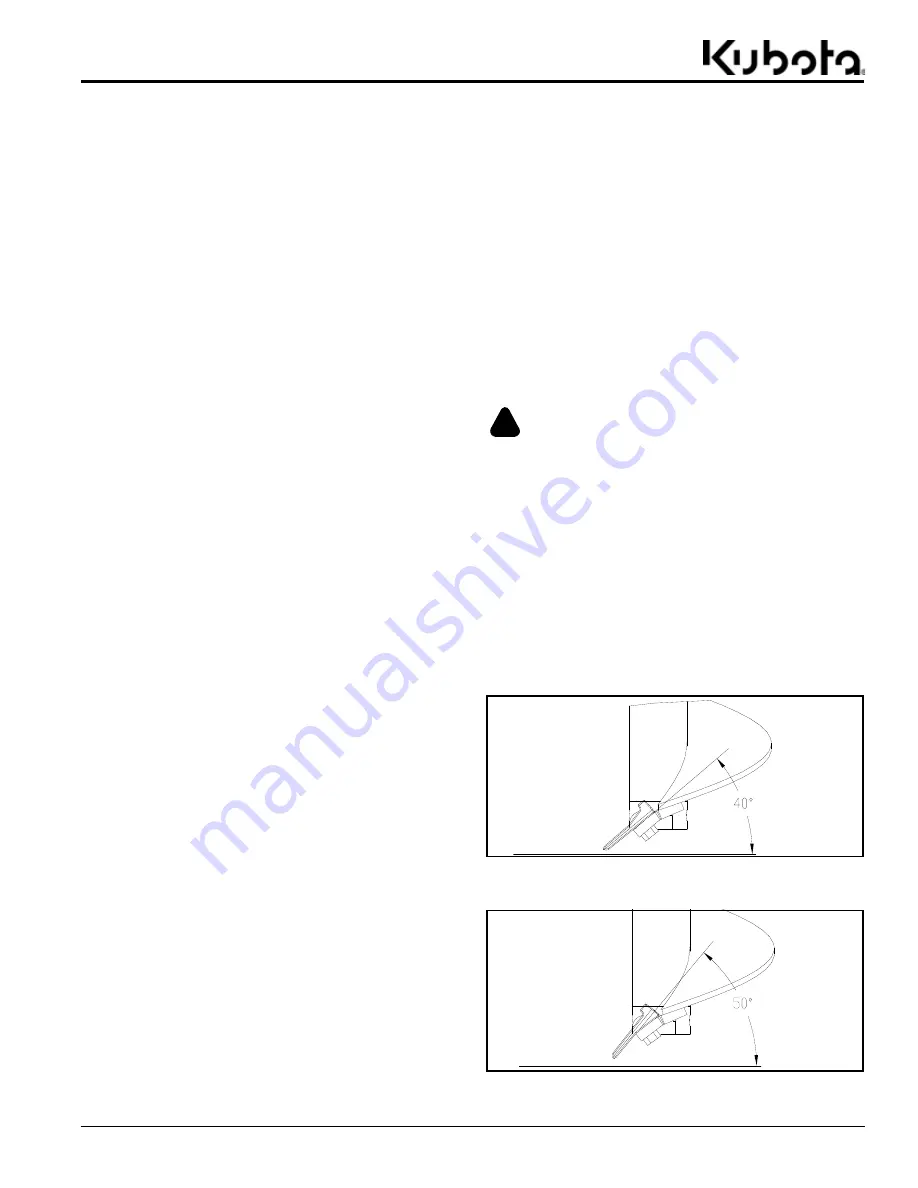

Dual-Angle Teeth

Refer to Figure 2-1 & Figure 2-2:

The Auger is shipped with teeth mounted at 40 degrees

(see Figure 2-1). If you are experiencing difficulty in

penetrating the soil, they can be turned over and

mounted at 50 degrees (see Figure 2-2) for a more

aggressive bite. Be sure to tighten all mounting hardware

to the proper torque when securing teeth to the Auger.

See

“Torque Values Chart for Common Bolt Sizes”

on

page 27 for torque ratings.

Auger Teeth Mounted at 40 Degrees

Figure 2-1

Auger Teeth Mounted at 50 Degrees

Figure 2-2

25598

25598