Submersible motor pumps (100 mm)

5

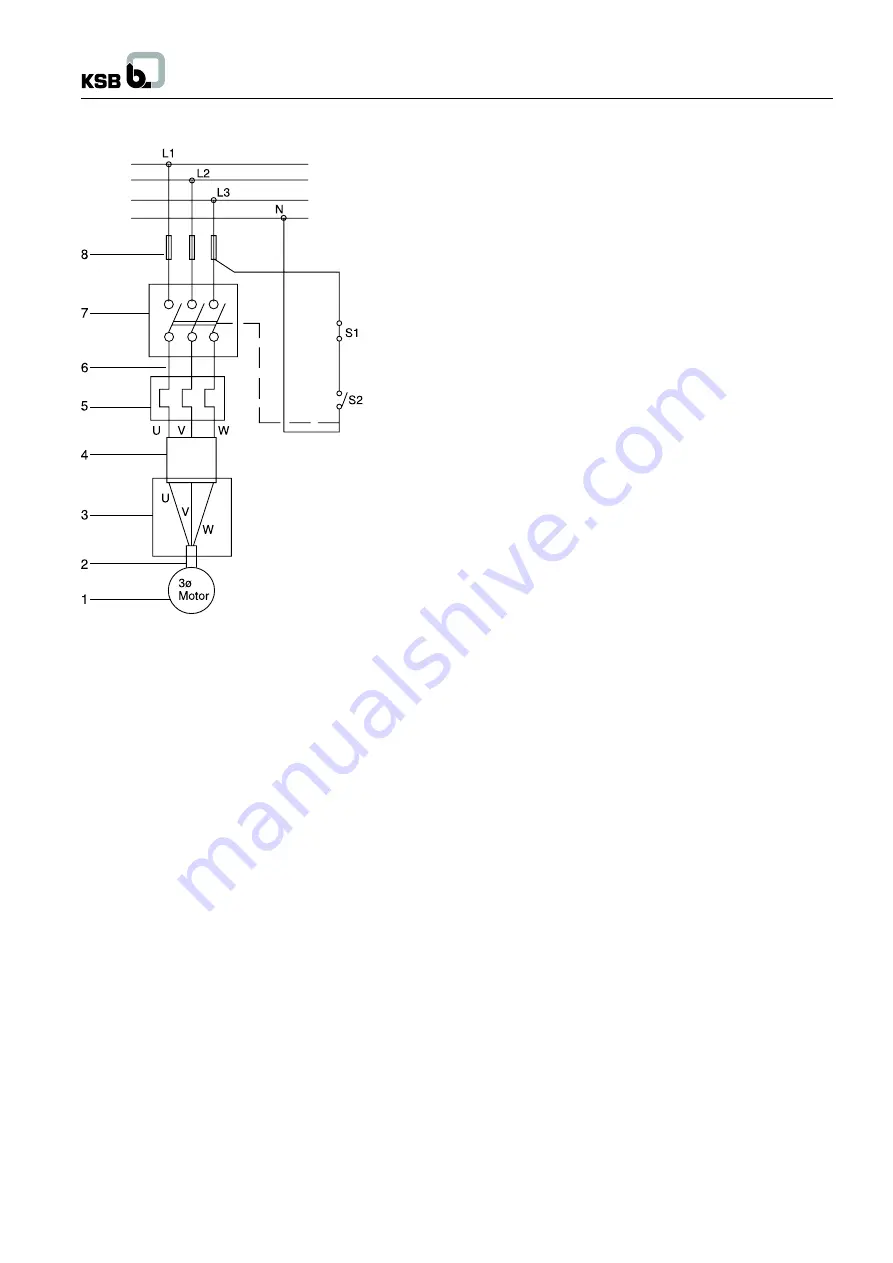

2.4.2 For three-phase motor

1. Submersible motor

2. Motor cable

3. Cable designation

4. Connected cable

5. Overload relay (thermal type)

6. Leads

7. Electro-magnetic switches

8. Fuses

L1, L2, L3 = Line supply

U, V, W

= Leads

N

= Neutral

S1, S2

= Push buttons

* Overload relay must be thermal type.

3

Commissioning and start up

3.1

Verification of rated current

Please refer to the motor nameplate for the values of rated current

required for relay setting.

3.2

Switching ON of mains

The pumping set should be switched on only if it is fully immersed

in the water.

3.3

Checking the direction of rotation

For three-phase motors

1. Let the pumping set run for a short time against a closed

discharge valve, in both the directions of rotation and check

the flow. Reversing of two points of connection, reverses

the direction of rotation. The higher flow rate gives the

direction of rotation. OR

2. Using pressure gauge, check the discharge pressure in both

the direction of rotations. The higher value corresponds to

the correct direction of rotation. OR

3. By visual inspection see the flow rate in both cases. If water

comes out up to the short length through the raiser pipe, flow

rate is lower while if it comes farther, results in higher flow

rate. The higher flow indicates the correct direction of rotation.

For Single-phase motors

In case of single-phase AC motors the direction of rotation of the

motor itself corresponds to the correct direction of rotation of the

pump, irrespective of mode of connection to the power supply.

3.4

Discharge valve position during initial start-

up

During initial start-up the pump should run with the discharge

valve slightly open (approx. 1/3 of full opening). The water is

examined for sand content (The permissible sand contents for

warranty is 50 mg / liter) at this stage it is important that pump is

run continuously without stooping (if pump is stop, sand will settle

inside the pump and pump is block resulting in damage) till the

sand content in the water falls to an unnoticeable level

OR Flush

the bore well completely before new pump installation.

3.5

Operation against a closed discharge valve

Pumps should not be allowed to run against a closed discharge

valve for longer than 5 minutes. This would cause the water in

the pump to warm up quickly and the heat would be transferred

to the motor, which causes a risk to the motor.

3.6

Operation against a throttled discharge valve

If the pump set is to be operated against a throttled discharge

valve for a prolonged period of time, the minimum rate of flow

should be at least 10% of flow at the best efficiency point * (BEP)

of the characteristic curve, this must be observed in order to

reduce noisy operation and the overheating of the pump set.

* For best efficiency point (BEP) of the characteristic curve

consult with KSB dealer.

Actual start-up

• Check the power supply condition as per the name plate.

• Do proper earthling.

• Fix the pressure gauge before discharge valve.

• Set the relay as per current value given on name plate and

start the pump.

• Set the duty parameters as per value given on name plate by

control valve.

• Pump should run always on duty point specified on name plate

3.7

Operating limits of pump

Operational safety requirements stipulate that pump may only

be operated continuously within the flow rate and pump head

limits which are specified on nameplate. Otherwise ±10% of best

efficiency flow rate should be the pump operation range, provided

that motor is not overloaded. (For ensuring this the motor current

should not exceed as specified on name plate).

3.8

Switching frequency

In order to prevent the motor from heating up excessively due to

many switching cycles, a maximum of 15 starts per hour are

permitted with a minimum of 3 minutes interval as a shut down

period between two successive starts.