7 Servicing/Maintenance

27 of 50

8417.8/20-EN

Also specify the following data:

▪

Part number and description

▪

Quantity of spare parts

▪

Shipping address

▪

Mode of dispatch (freight, mail, express freight, air freight)

7.3 Servicing/Inspection

7.3.1 Supervision of operation

The service life can be extended by taking the following measures:

▪

Checking the function by actuating the valve at least twice a year

7.3.2 Dismantling the valve

7.3.2.1 General information/Safety regulations

DANGER

Valve under pressure

Risk of injury!

Leakage of hot and/or toxic fluids!

Risk of burns!

▷

Depressurise the valve and its surrounding system prior to any maintenance

work and installation work.

▷

If there is fluid leakage, depressurise the valve.

▷

Allow the valve to cool down until the temperature of the fluid in all the

valve's chambers is lower than the fluid's vaporisation temperature.

WARNING

Unqualified personnel performing work on the valve

Risk of injury!

▷

Always have repair work and maintenance work performed by specially trained,

qualified personnel.

Always observe the safety instructions and information. (

In the event of damage you can always contact KSB Service.

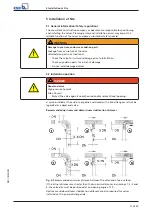

7.3.2.2 Preparing the valve

1. Move the valve into open position with the valve disc at an angle of 10°.

2. For valves with actuators, interrupt energy supply and make sure it cannot be

switched on again unintentionally.

3. Depressurise and drain the valve.

7.3.2.3 Removing the actuator

ü

The valve/actuator assembly has been removed from the piping.

1. Mark the actuator's alignment on the valve.

2. Undo the fasteners.

3. Using suitable lifting equipment, lift the actuator off the valve and place it on a

clean and level assembly surface.

Содержание BOAX-B

Страница 1: ...Butterfly Valve Installation Operating Manual ...

Страница 49: ......