3

ELECTRICAL CONNECTIONS

22

OPTIWAVE X400

www.krohne.com

06/2021 - 4006413503 - AD NEPSI OPTIWAVE x400 R03 en

3.6 Ex d ia / Ex iaD tD equipment

3.6.1 General notes

Ex d ia- and Ex iaD tD-approved equipment have two separate compartments. The electronics in

the electronics block compartment are Ex ia-approved and the terminal compartment is Ex d /

Ex tD-approved.

3.6.2 How to connect the electrical cables

Cable glands are supplied on customer demand. If you supply the cable glands, this part must

have a degree of ingress protection IP

≥

6X (IEC 60529). We recommend that you use a part that

has a degree of ingress protection IP

≥

68. Make sure that the cable gland is sealed.

Terminal compartment

•

If you connect electrical wires to the terminals in the flameproof terminal compartment, use

approved flameproof cable glands (M20×1.5 or

½

NPT). The cable glands must have a

certificate that agrees with GB 3836.1 and GB 3836.2. Obey the instructions given on the

certificate. Make sure that the tightening capacity of the cable gland is applicable to the

diameter of the electrical wire.

•

If you use conduits to connect electrical wires to the terminals in the flameproof terminal

compartment, obey the instructions that follow. Make sure that the conduits are correctly

attached and the flameproof compartment is sealed. The conduits must have a certificate

that agrees with GB 3836.1 and GB 3836.2. Use conduit stopping boxes that agree with

precautions given in the certificate and data in standards related to the installation of the

conduit.

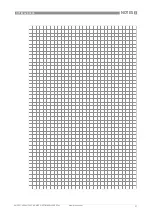

Figure 3-4: Compartments in Ex d ia- and Ex iaD tD-approved equipment

1

Electronics block (Ex ia) compartment

2

Terminal (Ex d / Ex tD) compartment

DANGER!

If you must open the electronics block compartment to remove the electronics blocks for

servicing, de-energize the device. It is not necessary to disconnect the wires from the Ex d /

Ex tD terminals.

If you must remove the terminal block for servicing, do not open the terminal compartment in a

potentially explosive atmosphere.

WARNING!

Use only Ex d-approved cable glands and adaptors for Ex d applications. Use only Ex tD-

approved cable glands and adaptors for Ex tD applications.