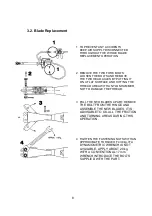

3.2. Blade Replacement

1 TO PREVENT ANY ACCIDENTS

KEEP AIR SUPPLY DISCONNECTED

THROUGHOUT THE WHOLE BLADE

REPLACEMENT OPERATION

2 REMOVE THE TWO FORK BOLTS.

LOOSEN THE BOLTS AND REMOVE

THE TWO HEAD AXLES BY PUTTING IT

ON A FLAT SURFACE AND HITTING THE

THREAD AREA WITH A NYLON HAMMER,

NOT TO DAMAGE THE THREAD.

3 PULL THE TWO BLADES APART. REMOVE

THE BOLT FROM THE HINGE AND

ASSEMBLE THE NEW BLADES. IT IS

ADVISABLE TO OIL ALL THE FRICTION

AND TURNING AREAS DURING THIS

OPERATION.

4 TIGHTEN THE FASTENING NUTS WITH AN

APPROXIMATE TORQUE OF 4mt/kg. IF A

DYNAMOMETRIC WRENCH IS NOT

AVAILABLE, APPLY ABOUT 20 kg.

WITH A CONVENTIONAL 17 mm

WRENCH INTRODUCE THE BOLTS

SUPPLIED WITH THE PART.

8

Содержание KRC 8

Страница 1: ...PNEUMATIC REBAR CUTTER MODEL KRC 8 KRC 8 L INSTRUCTION MANUAL ...

Страница 12: ......

Страница 13: ...KRC 8 8 L ...