2

GB

This operators manual applies to the

Kongskilde combi cleaner type KDC 8000

Preface:

This users manual has been prepared in accord-

ance with EU-directive 2006/42/EC (Machinery

Directive).

Marking:

See enclosed Declaration of Conformity.

Description:

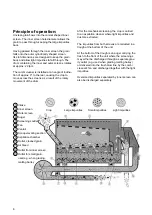

KDC 8000 is a combined screen- and aspiration

cleaner, designed for separation of grain and

impurities. The rotating screens are driven by an

electrical gear motor, and the cleaned crop can be

conveyed by the aspirator to a transport system.

The impurities are blown away together with the

aspirator air, and should be separated through a

cyclone and collected.

The cleaner can be equipped with screens

containing different hole sizes, depending on the

nature of the crop.

Capacity varies depending on the crop to be pro-

cessed, up to 80 tonnes per hour in easy floating

crop, depending on the requirements towards purity

of the crop.

The cleaner is primarily designed to be used for

pre cleaning of grain, corn, canola, sun flower

and beans from larger and smaller impurities.

Furthermore, the cleaner can be used for grading of

malting barley.

The cleaner should be feed continuously.

Typical application:

The combi cleaner has been designed for the pre-

cleaning of wheat, barley, rye, oats, rapeseed,

maize, peas, soybeans and sunflower for larger and

minor impurities.

Warning notes:

• Take care that all guards are in correct position

and fixed during operation.

• Always stop the combi cleaner prior to repair

and maintenance and avoid unintentional start of

the combi cleaner. Lock e.g. the on/off switch on

the built in control box or install a safety switch

mounted in the electrical installations to avoid

unintentional start of the cleaner.

• Only turn the screen drum manually when re-

placing the screens. Never turn the screen drum

by switching on the gear motor, when replacing

the screens.

• Use always gloves when replacing screens. The

screens may have sharp edges.

• Never put the hand in the outlet of the trough

auger.

• Never leave the outlet open, while the cleaner is

in operation. Connect the outlet to a container or

to a min. 800 mm long OK200 pipe, to prevent

access to the rotating parts.

• Never put your hand into the inlet or outlet open-

ing of the blower during operation.

• All electrical installations must be effected ac-

cording to the current legislation.

• In case of abnormal vibrations or noise, stop the

cleaner immediately and investigate. If in doubt,

call in expert assistance for repair and mainte

-

nance.

• Mount the cleaner on a solid and plane base, to

avoid the cleaner tipping over.

• If the cleaner is to be moved, use the four lift-

ing points in the corners (marked with the chain

symbol) or use a forklift or the like grabbing in

the rails under the base frame of the cleaner

at the indicated points. The forks must be long

enough to lift in both sides of the cleaner.

Warning signs:

Avoid accidents by always following the safety

instructions given in the manual and on the warning

signs placed on the cleaner.

Safety signs without text are used on the machine.

The signs are explained below.

Read carefully the manual

before using the cleaner, and

observe the warning signs on

the cleaner.

Содержание KDC 8000

Страница 1: ...KDC 8000 Combi cleaner Manual Brugsanvisning...

Страница 35: ...35...