• Set parking brake switch (2) to ON (operation) position (A)

to apply the parking brake, then put blocks in front of and

behind the tires to prevent the machine from moving.

• Do not touch the control levers or steering system. If it is

necessary to operate the control lever or steering system,

always give a signal to your fellow workers and have them

take refuge to a safe place.

TURN OFF ECSS SWITCH BEFORE PERFORMING INSPECTION AND MAINTE-

NANCE

Before starting the inspection and maintenance, lower the bucket to the ground and turn the ECSS switch to

OFF position, then stop the engine. Never turn the ECSS switch to ON position during the inspection or mainte-

nance.

PRECAUTIONS WHEN INSTALLING, REMOVING, OR STORING ATTACHMENTS

• Appoint a leader before starting removal or installation operations for attachments.

• Place attachments that have been removed from the ma-

chine in a stable condition so that they do not fall. And take

steps to prevent unauthorized persons from entering the

storage area.

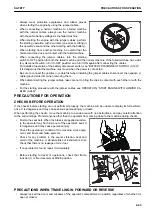

PRECAUTIONS FOR WORKING AT HIGH PLACES

When working at high places, use a step ladder or other stand to ensure that the work can be performed safely.

There is a danger falling from high place that can lead to serious personal injury or death.

PRECAUTIONS WHEN WORKING UNDER MACHINE OR WORK EQUIPMENT

Machine or work equipment may fall, and it is dangerous that serious personal injury or death may occur. Al-

ways observe the following.

• Do not perform inspection and maintenance under the work equipment which is not lowered to the ground.

Always lower the work equipment to the ground when performing inspection and maintenance.

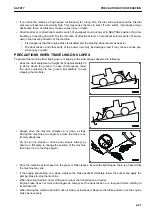

• Make sure the hoists or hydraulic jacks you use are in

good repair and strong enough to handle the weight of the

component. Never use hydraulic jacks at places where the

machine is damaged, bent, or twisted. Never use if the

strand of wire rope is frayed, twisted or pinched. Never use

bent or distorted hooks.

• If it is necessary to raise the work equipment or a compo-

nent and then go under it to carry out inspection or mainte-

nance, support the work equipment or component securely

with blocks and stands (1) strong enough to support their

weight. If the work equipment or component is not support-

ed, they may come down, causing serious personal injury or death.

,&

,&

SAFETY

PRECAUTIONS FOR MAINTENANCE

2-35

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

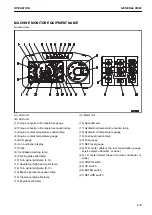

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...