DEFINED LIFE PARTS LIST

No.

Periodical replacement parts

Ask your Komatsu distributor

for replacement.

1

Fuel system

Fuel hose

Spill hose

2

Steering system

High pressure circuit hose

3

Brake system

Brake oil pressure hose

4

Torque converter, trans-

mission system

Transmission circuit hose

5

Work equipment hydraulic

system

Main pump delivery hose

Main pump delivery hose other than described

above

Main pump LS hose

Hydraulic drive fan hose (Intake fan)

Hydraulic drive fan hose (Exhaust fan)

External work equipment hose

•

Lift cylinder hose

•

Bucket cylinder (bottom) hose

•

Bucket cylinder (head) hose

•

Hydraulic tank hose

•

Main valve hose

•

ECSS hose

6

Others

PPC accumulator

METHOD FOR LUBRICATING DRIVE SHAFT

Use the special grease for drive shaft, and perform greasing every 4000 hours or every 2 years.

If the special grease is not used but common lithium base grease is used, perform greasing every 1000 hours

after then.

Part No. of special grease for the drive shaft: 56B-20-19910 (operating temperature range: -35 to 160 °C)

1.

Remove inspection windows (1) and (2) of the undercover.

2.

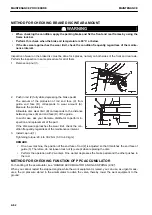

By using a grease pump, pump in grease through the

grease fittings shown by arrows.

For the greasing, stop the drive shaft when grease fitting

(A) of the centre drive shaft comes to the position shown in

the figure, and then pump in grease.

The position of the grease fitting at this point is the one cir-

cled and indicated by the arrow in the following figure

when viewed from the rear side of the machine.

3.

After greasing, wipe off any old grease that is pushed out.

4.

Install inspection windows (1) and (2) of the undercover.

• Centre drive shaft (2 places)

MAINTENANCE PROCEDURE

MAINTENANCE

4-72

Содержание WA480-8

Страница 2: ......

Страница 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Страница 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Страница 69: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 76: ...Outside of cab 1 Slow blow fuse 2 Dust indicator 3 Articulation lock pin 4 Toolbox GENERAL VIEW OPERATION 3 8...

Страница 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

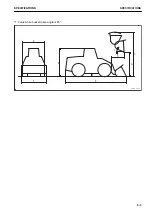

Страница 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Страница 324: ......

Страница 325: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Страница 402: ......

Страница 403: ...SPECIFICATIONS 5 1...

Страница 405: ...1 Value when bucket dump angle is 45 B I A G E H F D C 9 J W0 1 4 5 6 SPECIFICATIONS SPECIFICATIONS 5 3...

Страница 406: ......

Страница 422: ......

Страница 423: ...REPLACEMENT PARTS 7 1...

Страница 439: ......

Страница 440: ...WA480 8 WHEEL LOADER Form No VENAM51500 2018 KOMATSU All Rights Reserved Printed in Europe 07 2018...