2.

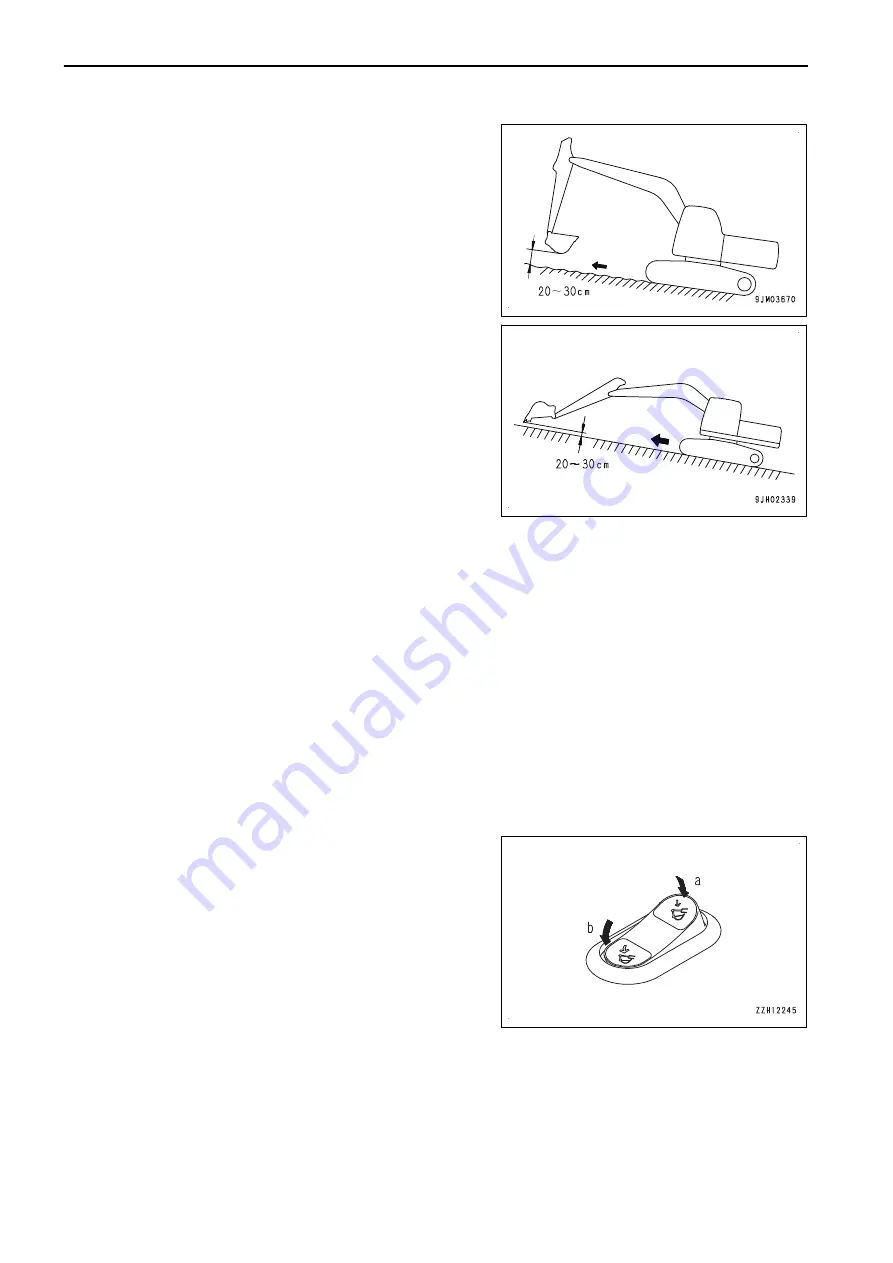

When travelling up a steep hill of more than 15°, set the

work equipment to the posture shown in the figure.

When travelling up a steep slope, extend the work equip-

ment to the front to improve the balance, keep the work

equipment approximately 20 to 30 cm above the ground,

and travel at low speed.

Braking on downhill slope

Put the travel lever in NEUTRAL position. This will cause the brake to be automatically applied.

If engine stops on slope

If the engine stops when travelling uphill, move the travel levers to NEUTRAL position, lower the bucket to the

ground, stop the machine, then start the engine again.

Pay attention to DEF level

Before working on a slope or travelling on a rough ground, check DEF tank and add sufficient amount of DEF as

necessary. If the remaining DEF level becomes low, sudden drop of its level or abnormality in urea SCR system

may be detected. If DEF level caution lamp or DEF system caution lamp lights up in red, move the machine to a

level place immediately and add DEF.

METHOD FOR ESCAPING FROM MUD

Always operate carefully to avoid getting stuck in mud. If the machine does get stuck in mud, do as follows to

get the machine out.

Set the machine push-up switch to the high-pressure setting

position (b).

The machine can easily get out since the boom pressing force

against ground increases.

MACHINE OPERATIONS AND CONTROLS

OPERATION

3-194

Содержание PC700LC-11

Страница 2: ......

Страница 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Страница 66: ......

Страница 67: ...OPERATION Please read and make sure that you understand the SAFETY section before reading this section 3 1...

Страница 73: ...REMARK The above figure does not show all of the caution lamp symbols OPERATION GENERAL VIEW 3 7...

Страница 316: ......

Страница 317: ...MAINTENANCE Please read and make sure that you understand the SAFETY section before reading this section 4 1...

Страница 331: ...Fuel main fil ter cartridge Replace Replace Replace Replace MAINTENANCE MAINTENANCE SCHEDULE 4 15...

Страница 375: ...A Important inspection part F Front Revolving frame Center frame MAINTENANCE MAINTENANCE PROCEDURE 4 59...

Страница 396: ......

Страница 397: ...SPECIFICATIONS 5 1...

Страница 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Страница 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Страница 426: ......

Страница 427: ...REPLACEMENT PARTS 7 1...

Страница 434: ......

Страница 442: ...PC700LC 11 HYDRAULIC EXCAVATOR Form No UENAM01321 2017 KOMATSU All Rights Reserved Printed in Belgium 09 2017...