1265599-2A-A

2

1265599-2A-A

3

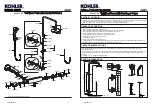

How to Install the Faucet

To perform installation, installer must provide G1/2

˝

female supply fittings(1),

spaced 150mm apart and horizontally. The supply fittings should be vertical and

not beyond the finished wall. Hot supply pipe must be located on the left.

Flush the water supply pipes thoroughly to remove debris.

Install the two offset connectors(2) into the hot and cold supply pipes. Use

appropriate thread sealants or thread tape on pipe threads. Adjust the

center-to-center distance between the connectors to 150mm and horizontally.

They should extend 29mm beyond the finished wall. Thread the escutcheons(3)

onto the connectors until they are against the finished wall.

Put the washers(4) into the nuts(5), thread the nuts to connectors. Tighten the

nuts with strap wrench or soft cloth between product and regular wrench.

How to Install the Column

Select a location in vertical wall to install shower column according to rough-in

dimensions. Drill the lower hole as anchors(6) diameter and lower base(8-1)

position in the finished wall(

NOTE:

The arrow in the base is upward). Press

anchors into the hole, secure the base by the screws(7).

Rehearse the slide bar kit(9) installation for the upper base(8-2) mounting location

determination. Slide the tube joint(10) onto the slide bar kit, and connect them to

the base(

NOTE:

The arrow in the base is up). Install the screws(12) into the tube

joint with the hex wrench(11), and tighten them.

Place the slide bar and the body against the finished wall. Connect the lower base

and the diverter body kit(13). Position and tighten them by hex wrench. Mark the

hole of upper base(8-2) with a pencil. Uninstall the slide bar kit and tube joint.

(

NOTE:

Don’t lose the screws.)

Drill holes on the mark. Press the anchors into the holes. Secure the upper

base(8-2) by the screws. Install the tube joint(10) to the base(8-2) and tighten

them by screws. Reinstall the slide bar kit with escutcheons(14) to the bases.

Tighten the screws with the hex wrench. Screw the escutcheons with the bases

until against the finished wall.

Install the tube kit(15) into the slide bar kit. Install the nut(16) onto the tube kit

with soft cloth between internal hole of the nut and the tube kit. Then screw the

nut onto the slide bar kit with strap wrench or soft cloth between the nut and

regular wrench.

INSTALLATION

How to Install the Showerhead

Turn the diverter handle(21), run hot and cold water for about one minute to remove

any debris before the showerhead(26) is installed.

Take out the washer(27) and install the restrictor(28) into the showerhead if needed,

reinstall the washer. Tighten the showerhead onto the tube kit outlet with strap wrench.

CARE AND MAINTENANCE

Ensure that all connections are tight. Ensure that the handle is in the off position. Turn on the drain and main water

supply, and check for leaks. Repair as needed. Remove the handspray. Run hot and cold water through the faucet for

about one minute to remove any debris. Check for leaks. Shut off the faucet, and reinstall the handspray.

INSTALLATION CHECKOUT

Verifications and Setting

Make sure that the water feeds of the faucet have reach their highest temperature by

letting the water run sufficiently. With the selector in position 37°C, the temperature of

the water coming out of the faucet must be within a range of 36°C and 38°C, as

measured by a thermometer. If this is not the case, the installer can adjust the setting.

Proceed with the setting as follows: Remove the handle plug. Untighten the screw

with the screwdriver, remove the handle kit. With the faucet on “cold” normal water

flow, slowly turn the temperature selector(always in the same direction) until water at

37°C is obtained. If the temperature goes over 38°C, go back to the “cold” setting and

set again. When the temperature is stabilized, without turning the cartridge spindle,

make sure the reference mark of the temperature handle aligned with the number 37.

Tighten the screw, put on the handle plug as shown.

OPERATION INSTRUCTIONS

CLEANING INSTRUCTIONS

All Finishes: Clean the finish with mild soap and warm water. Wipe entire surface completely dry with clean soft cloth.

Many cleaners may contain chemicals, such as ammonia, chlorine, toilet cleaner etc. which could adversely affect the

finish and are not recommended for cleaning.

Do not use abrasive cleaners or solvents on Kohler faucets and fittings.

2

Hot

Cold

1

6

7

12

8-2

14

6

7

12

8-1

14

13

16

15

10

11

9

How to Install the Handspray and Hose

Remove the guards on the outlet connectors of 500mm length hose(18). Connect

the outlet(17) to the connector(20) with the hose(18), and tighten.

Turn the diverter handle(21), run hot and cold water for about one minute to

remove any debris.

Remove the guards on the outlet connectors of 1500mm length hose(22). Tighten

one connector(22-1) of the hose to the connector(23). Put the restrictor(24) into

the handspray(25) inlet if needed. Tighten the handspray to another

connector(22-2) of the hose.

Number 37

Round laser mark

Spindle

The filters(29) protecting

the faucet device may get

obstructed and reduce

water flow. When this

happens, unscrew the

bushes(30, left thread) by

a wrench (12mm) and

take out the nuts(31),

filters(29) and the check

valves(32) after removing

the faucet. Clean the

filters by soaking them in

warm vinegar. Reinstall

them as the figure.

(

NOTE:

Check valves

should reinstall as original

orientation).

29

30

31

32

Notch

Stop pin

Fig.4

Fig.3

Stop pin

Notch

Fig.1

Fig.2

Cartridge

Nut

Stopper

Groove

Round mark

Fig.5

Very hard water can obstruct the filters on the

thermostatic cartridge and reduce the flow of water.

Please clean the cartridge as follows: Shut off the water

supply of the faucet and open the water flow handle, then

proceed to remove the cartridge. The cartridge is sense

organ, please be careful.

Mark sure the reference mark is aligned with number 37

before your action. Remove the handle kit(Fig.1), unscrew

the nut and stopper(Fig.2). Remove the cartridge

cautiously(Fig.2). Clean the thermostatic cartridge by

soaking it in warm vinegar. After cleaning, install the “stop

assembly” back to the cartridge, adjusting the stop pin into

the notch(Fig.3). Install the assembly cartridge and stop in

the body, adjusting the stop pin into the notch(Fig.4).

NOTE:

Do not turn the cartridge when reinstall it. If you

turned it without carefully, you should adjust it and be sure

that the round mark is correctly in line with the groove

(Fig.5), or readjust as per the steps of verification and

setting.

Install the temperature selector(without turning the spindle)

aligning the number 37 with the reference mark(Fig.1).

Tighten the handle with the screw. Put on the handle plug.

3

150mm

29mm

4

5

22

18

17

24

25

22-2

22-1

20

21

23

26

27

28