Operating Instructions

for

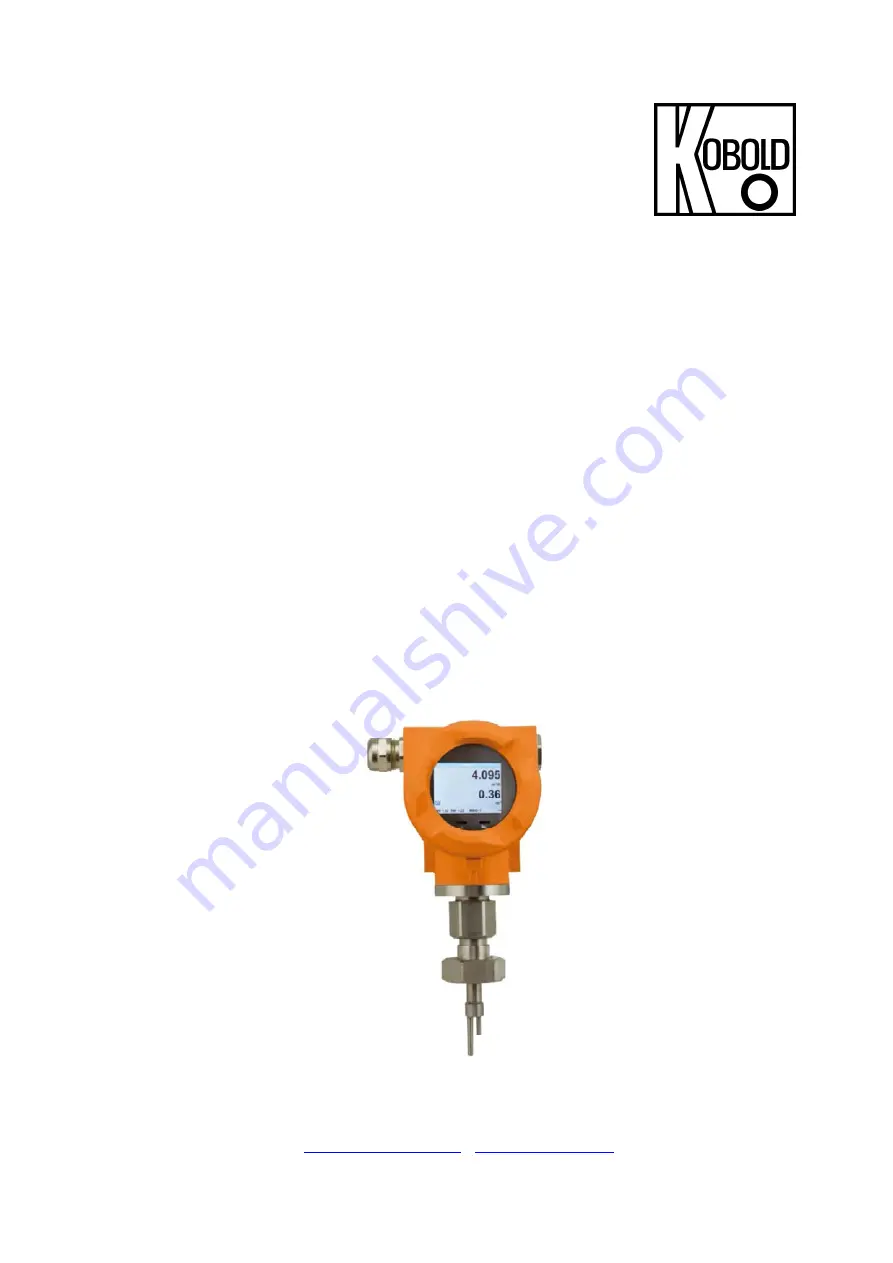

Thermal Energy Flowmeter

for gases

Model: KEC-1

O

O

r

r

d

d

e

e

r

r

f

f

r

r

o

o

m

m

:

:

C

C

A

A

B

B

r

r

i

i

g

g

g

g

s

s

C

C

o

o

m

m

p

p

a

a

n

n

y

y

622 Mary Street; Suite 101; Warminster, PA 18974

Phone: 267-673-8117 - Fax: 267-673-8118

[email protected]

-

www.cabriggs.com