4 OF 7

·

Store idle tools.

When tools are not is use, store them in a dry, secure place out of the reach of

children. Inspect tools for good working condition prior to storage and before re-use.

·

Use only accessories that are recommended

by the manufacturer for your model.

Accessories that

may be suitable for one tool may create a risk of injury when used on another tool.

·

Keep guards in place

and in working order.

·

Never leave tool

running unattended.

·

USE COMPRESSED AIR ONLY.

Use clean, dry and regulated compressed air to power this tool.

Never use oxygen, carbon dioxide or any other bottled gas as a power source for this tool.

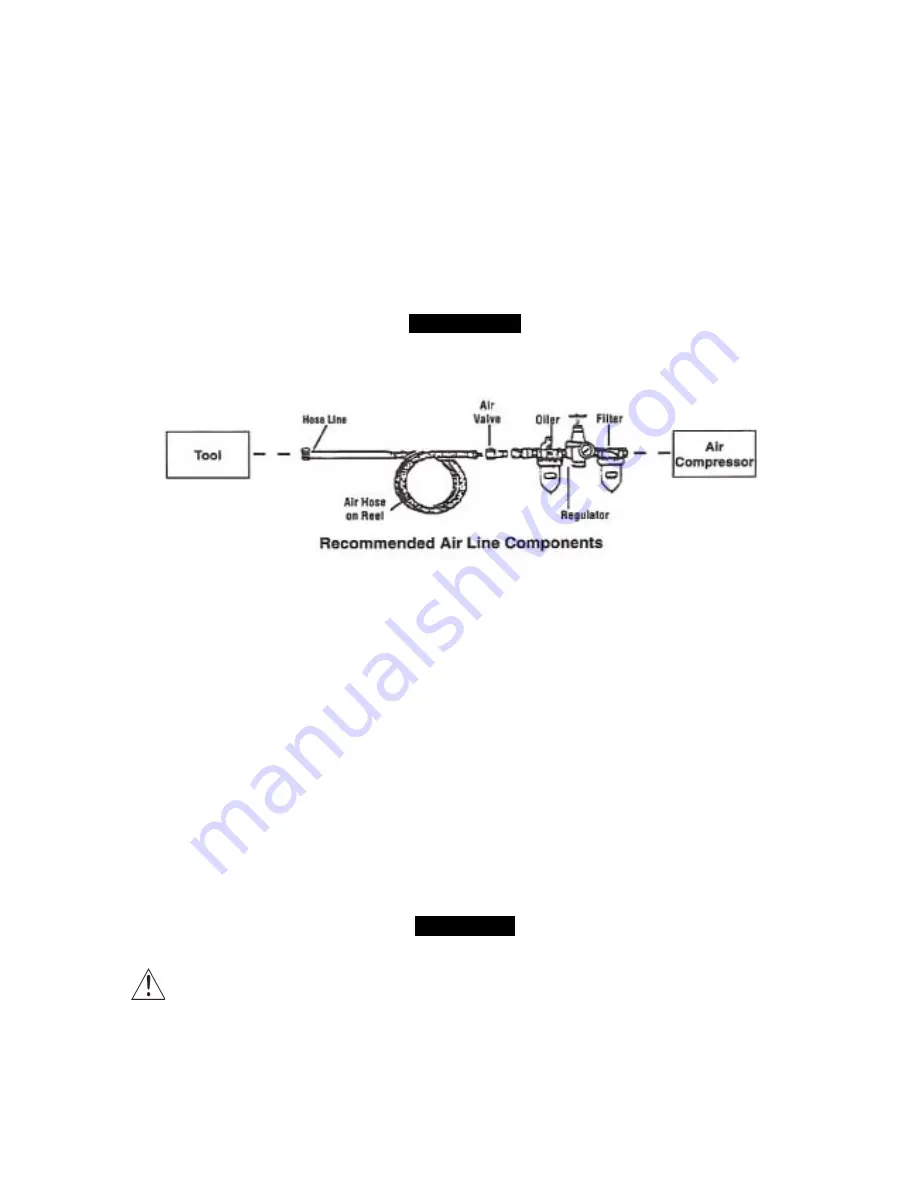

TOOL SET UP

Fig. 1 (Above) shows an optimal set-up that includes an inline filter, regulator and oiler. All of these

components are sold separately.

NOTE:

If you are not using an automatic oiler system, before operation, add a few drops of

Pneumatic Tool Oil to the airline connection. Add a few drops more after an hour of continual use.

1. Prepare the 1/4in. air nipple to connect to the air inlet on the Air Scaler. First, wrap the

1/4in. air nipple with pipe thread seal tape (not included) before threading it into the inlet.

Connect the 3/8in. I.D. air hose (not included) to a quick-disconnect coupler (not included)

and then to the air nipple.

2. Turn on the air pressure on your compressor to 90 PSI. Do not exceed the recommended

air pressure of 90 PSI.

3. Check the air connection for leaks.

AIR SUPPLY

WARNING:

Ensure the air supply is clean and does not exceed 90 PSI while operating the tool.

Too much air pressure and unclean air will shorten the product life due to excessive wear, and may

cause damage and/or personal injury.

1. Make sure that the air valve (or trigger) is in the “off” position before connecting to the air

supply.

2. An air pressure of 90 PSI is required.