11

Wait until the engine is cold, turn the radiator cap counterclockwise until stops.

Do not press down while turning the cap. After any remaining pressure has been

relieved, remove the cap by pressing down and again turning it counterclockwise.

Add enough coolant to fill the radiator, and reinstall the cap. Be sure to tighten it

securely. Fill the r

up to the MAX mark with the engine cold.

overflow pot

3. If there is no

in the

, check whether the cooling system has

leadage and service it if necessary. Be sure that there is coolant in the radiator

and the

.

coolant

overflow pot

overflow pot

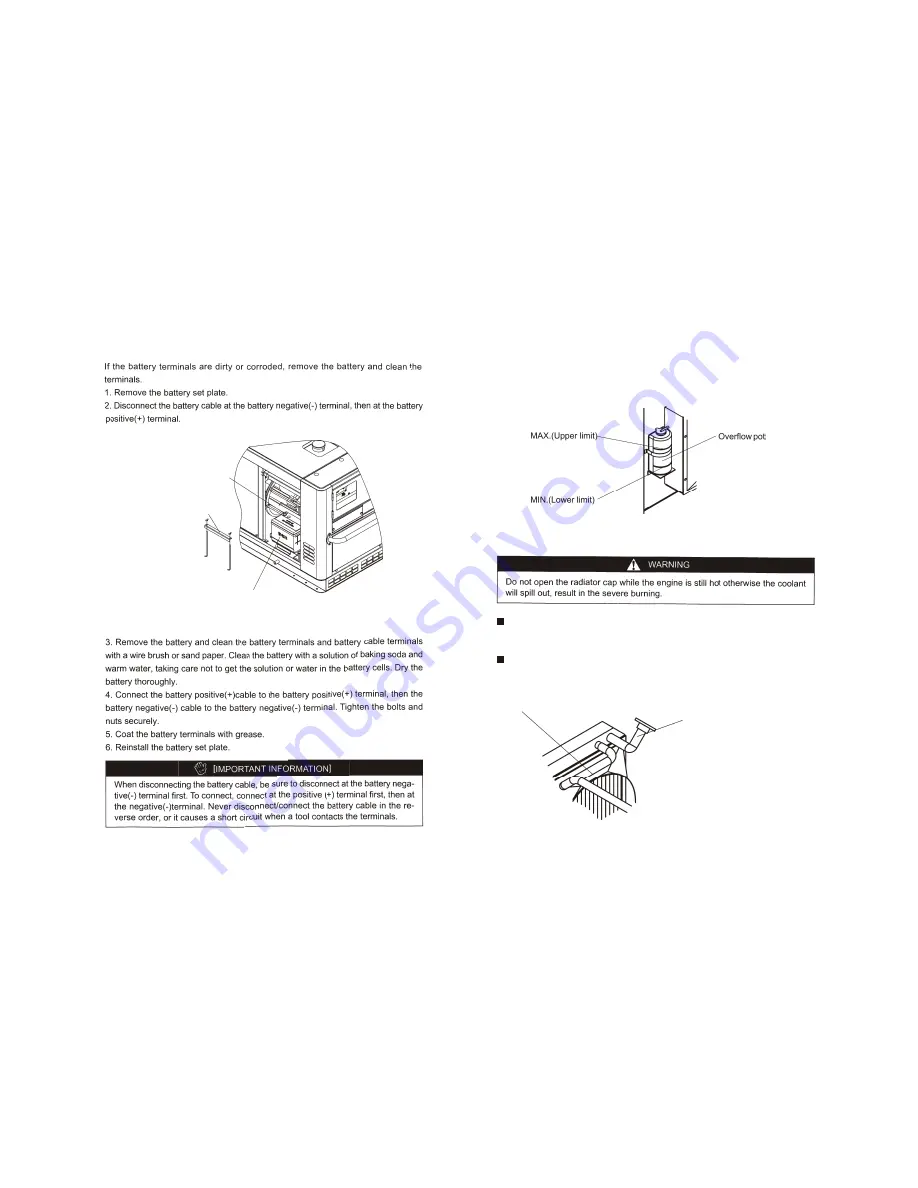

3.3 Coolant

1. Open the maintenance

2. Check the

level while the engine has the normal wording temperature. If

the level is approaching the "MIN" mark, refill

to "MAX" mark.

door.

water

coolant

Filling coolant liquid outler

Radiator

26

6.4 Clean the Battery

Negative terninal (-)

Battery set plate

Battery

Содержание KDE16EA

Страница 2: ......

Страница 15: ...9 3 2 Fuel 28 7 TRANSPORTING AND STORAGE 7 1 Transporting Handle Handle Lifting hook...