OPERATION

SETTING UP THE MACHINE FOR OPERATION

1. Depending on the material to cut, select and install the proper blade and set the proper blade speed.

2. Make sure the blade tension is adjusted and that the blade is tracking properly.

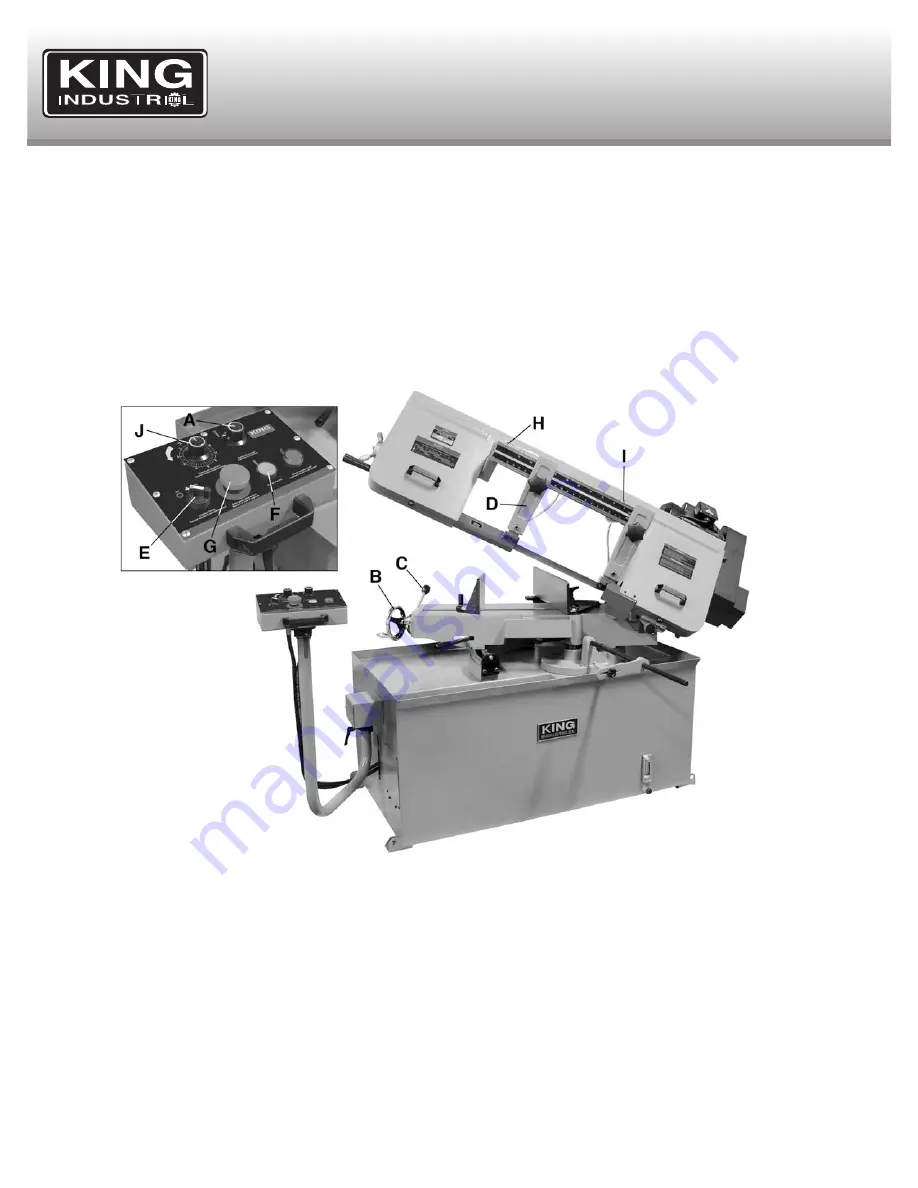

3. Raise the saw frame and close the feed on/off knob (A) Fig.26.

4. Place workpiece between the vise jaws. Adjust the stock for the desired length of cut, tighten the vise handwheel (B) and lower the cam lock

lever (C) to firmly secure workpiece.

5. Make sure the blade guide control arm (D) is adjusted as close as possible to the workpiece.

6. Turn the coolant selector (E) to the “On” position, then turn machine on by pressing the “On” button (F). Note: If the “Emergency stop/off”

button (G) is pressed, it needs to be twisted until it pops out or the bandsaw will not start. Just in case, keep your finger near the “Emergency

stop/off” button at all times during the operation. The bandsaw should run smoothly with little or no vibration.

7. Adjust the coolant flow using one or both coolant valves (H & I) above the control arms.

8. Turn the feed rate control knob (J) counterclockwise until the saw blade begins to lower, see the feed rate guideline section below as reference.

9. Proceed to cut through the workpiece. The motor and coolant pump will shut off upon completion of the cut.

FEED RATE GUIDELINES

When the feed rate control knob (J) Fig.26 is turned clockwise as far as it will go, the saw frame will not move down, but can be raised to the

up position. Turning the feed rate control knob counterclockiwise, the flow of oil from the cylinder is regulated and determines the speed at which

the saw frame will lower and the blade will feed through the work. Too many factors are involved to make tabulated data practical on feed rates.

As a general rule, an even downward pressure without forcing the blade gives best results. Burned chips indicate excessive feed, which

causes the teeth to break off as the blade overheats. The ideal feed rate is indicated by chips that have a free curl and this will give the fastest

cutting time and longest blade life.

OPERATIONAL TIPS

1. Let the blade reach full speed before engaging the workpiece.

2. Never start a cut with the blade in contact with the workpiece, and do not start a cut on a sharp edge.

3. Chips should be curled and silvery. If the chips are thin and powder like, increase your feed rate.

4. Burned chips indicate a need to reduce your blade speed.

5. Wait until the blade has completely stopped before removing the workpiece from the vise, and avoid touching the cut end—it could be very hot!

6. Use coolant when possible to increase blade life.

FIGURE 26