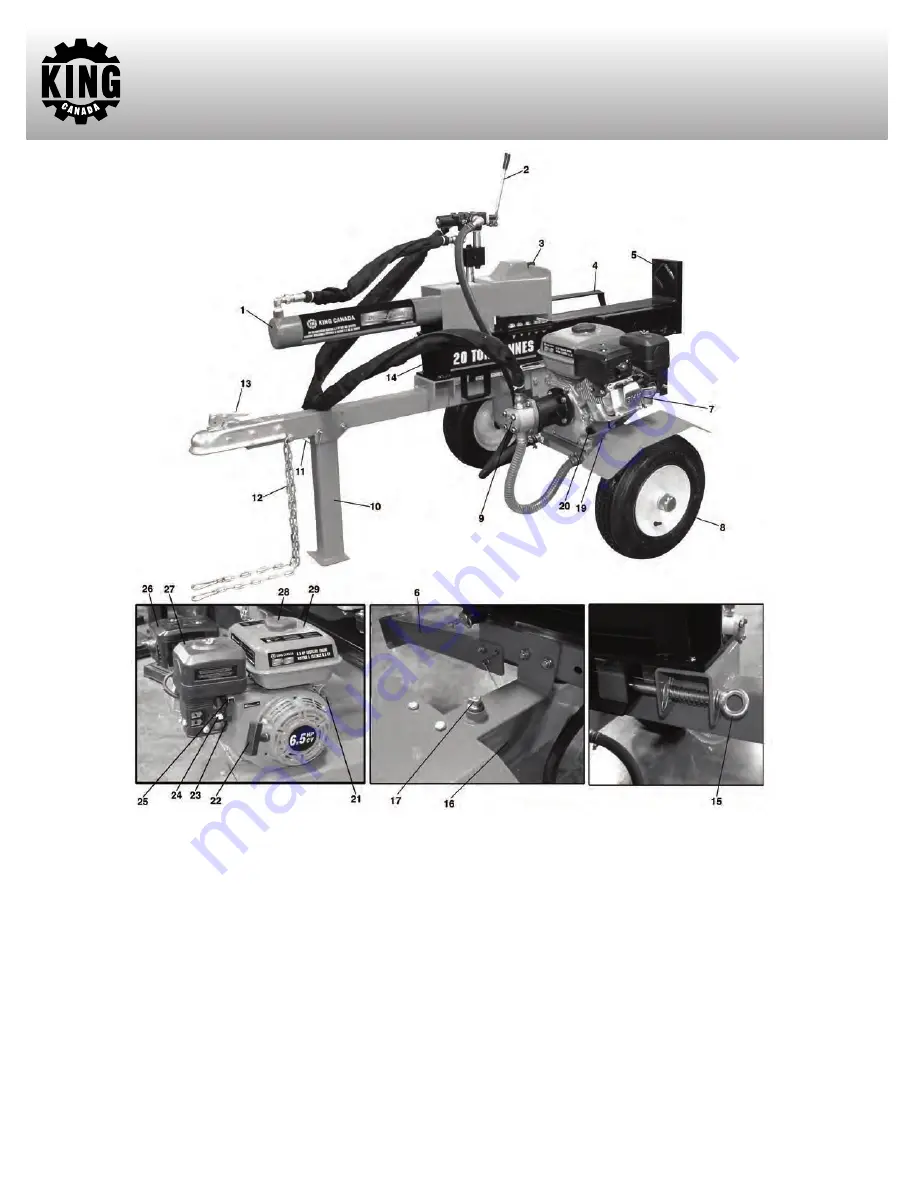

GETTING TO KNOw YOUR

GAS OPERATED LOG SPLITTER

1. Cylinder.

Pushes wedge to split wood.

2. Control lever.

Forward/neutral/return positions.

3. wedge.

4-way wedge splits wood into 4.

4. Log craddle.

Prevent logs from falling off the beam.

5. Endplate.

6. Rear outrigger leg.

7. Gas engine assembly.

8. DOT Pneumatic wheel.

Max speed of 70 km/h.

9. hydraulic pump.

10. Front outrigger leg.

11. Outrigger leg lock pin.

12. Towing safety chains.

13. 2” Ball coupler.

14. Beam.

15. Beam horizontal position lock pin.

16. hydraulic fluid axle/tank.

17. Dipstick for hydraulic fluid tank.

18. Spark plug/cover.

The spark plug must be check periodically for

carbon deposits and/or discoloration, see maintenance section.

19. Oil drain bolt.

20. Oil gauge dipstick.

Check the oil level using this oil gauge dipstick.

21. Power ON/OFF switch.

This switch must be switched to “ON” be-

fore pulling recoil starter.

22. Recoil starter.

Starts the engine.

23. Fuel Shut-off valve.

Regulates the flow of fuel to the engine. The

fuel shut-off valve must be fully opened before starting the engine.

24. Carburetor throttle lever.

Once the engine is started, move the trot-

tle lever to increase or decrease engine speed.

25. Choke lever.

Once the engine is started, it is necessary to gradually

move the choke lever to the “OPEN” position, see instructions futher

in this manual. On warm starts, choke is not needed.

26. Muffler.

Be careful, the muffler can get very hot during operation,

keep hands away.

27. Air cleaner element/cover.

Periodically the air cleaner filter must

be checked and maintained, see maintenance section.

28. Fuel cap.

Make sure the fuel cap is always screwed on tightly.

29. Fuel tank.

Unleaded gasoline only!