Page 11

PISTON BALANCED THROTTLING REPAIR MANUAL

CLEANING & INSPECTION

STEP 1

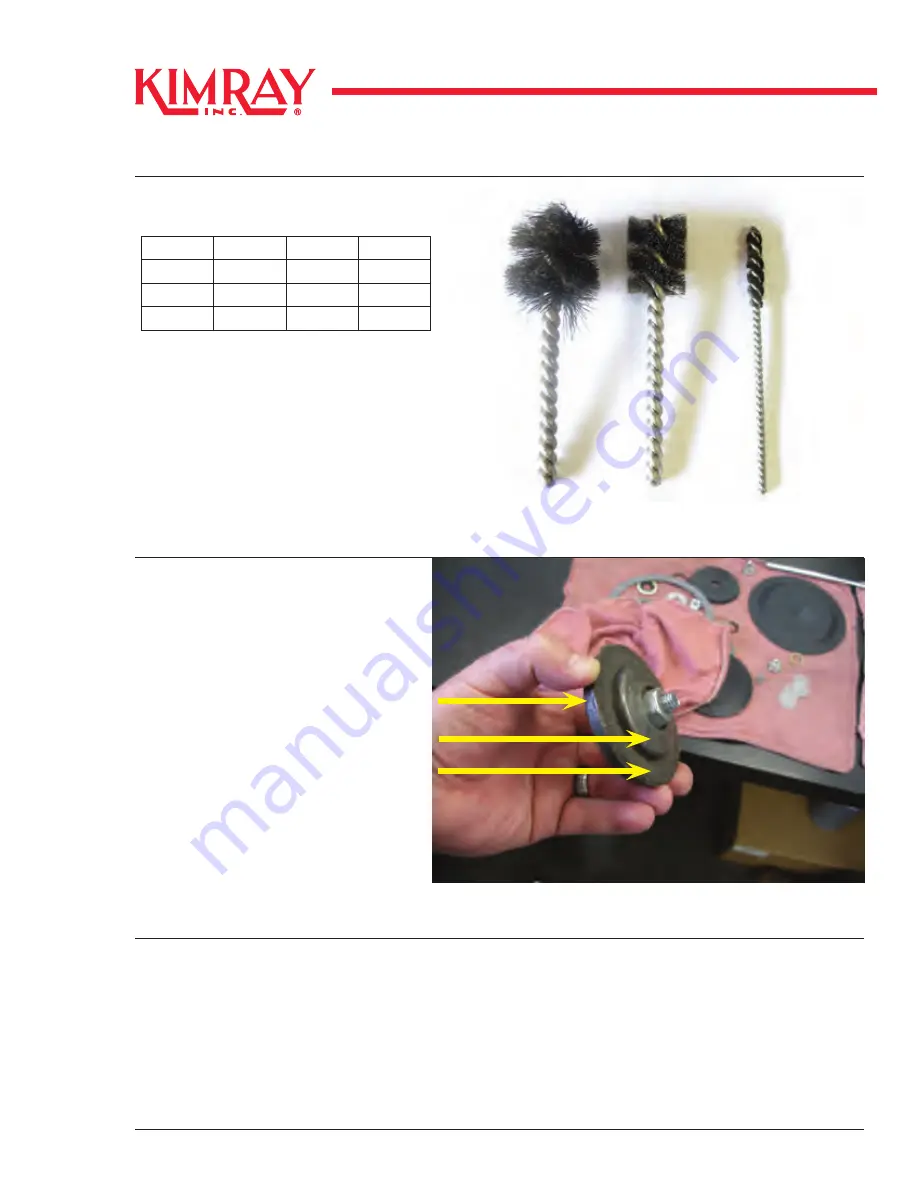

Cleaning

Diameter Wire Size Length Stem Dia.

1/4"

.004"

3-1/2"

1/8"

3/4"

.006"

3-1/2"

1/4"

1-1/4"

.008"

3-1/2"

1/4"

It is important to inspect all thread surfaces

for pits, debris and flat spots.

The listed wire brushes will allow you to

thoroughly clean virtually all threaded sur-

faces on Kimray products.

Often times the seat can-

not be removed and/or

replaced due to the length

of time in service. A seat

cleaning tool can be made

from a 3” ratio plug

(Fig. 1.1), a 2” ratio plug

(Fig. 1.2), and glue-on

sandpaper (Fig. 1.3). At-

tach the seat cleaning tool

to a speed wrench, make

flat contact and spin the

speed wrench to dress the

seat, inspect the seat for

scratches and repeat the

process as needed.

In the process of cleaning the valve there are a few essential areas that must be addressed:

1. All thread surfaces

2. Ensure all gasket material is removed.

3. Exterior free of solvents, debris and fluids if the product is to be re-painted.

4. Interior free of solvents, debris and fluids that may damage elastomers and affect O-ring / gasket seals.

www.kimray.com

Figure 1.1

Figure 1.2

Figure 1.3