18

Installation

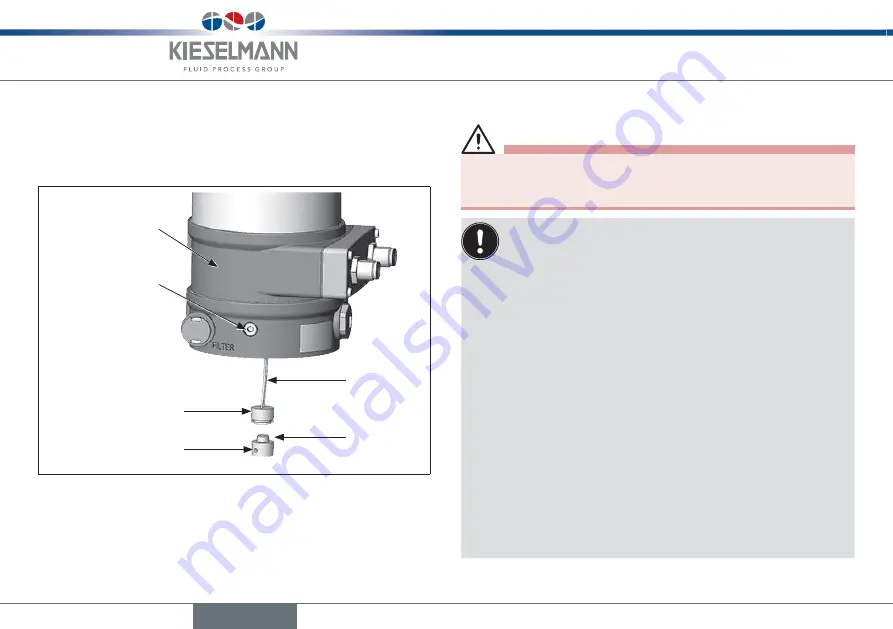

Type 8615500120-000 / 8615500130-000

→

Attach type 8615500120-000 / 8615500130-000 to the

actuator using both lateral fastening screws. In doing so, tighten

the screws only lightly (maximum tightening torque: 0.5 Nm).

Electrical con-

nection housing

Fastening screws

max. 0.5 Nm

Angle of rotation

sensor

Setscrew

Sensor cable

Magnetic

encoder

Fig. 8:

Installation on rotary actuators

10.6 pneumatic connection

Danger!

risk of injury from high pressure in the system/device.

▶

Before working on the system or device, switch off the pressure

and vent/drain lines.

observe the following for the proper functioning of the

device:

▶

The installation must not cause back pressure to build up.

▶

To make the connection, select a hose with sufficient

cross section.

▶

Design the exhaust air line in such a way that no water or

other liquid can get into the device through the exhaust

air port (3 or 3.1).

exhaust air concept:

▶

In compliance with the degree of protection IP67, an

exhaust air line must be installed in the dry area.

▶

always

maintain an applied control pressure of at least

0.5 ... 1 bar above the pressure which is required to

move the pneumatic actuator to its end position.

This ensures that the control behavior is not negatively

affected in the upper stroke range on account of too little

pressure difference.

▶

During operation, keep the fluctuations of the control

pressure as low as possible (max. ±10 %).

If fluctuations are greater, the control parameters mea-

sured with the

X.TUNE

function are not optimum.

English

Содержание 8615500120-000

Страница 93: ......

Страница 94: ...www kieselmann de...