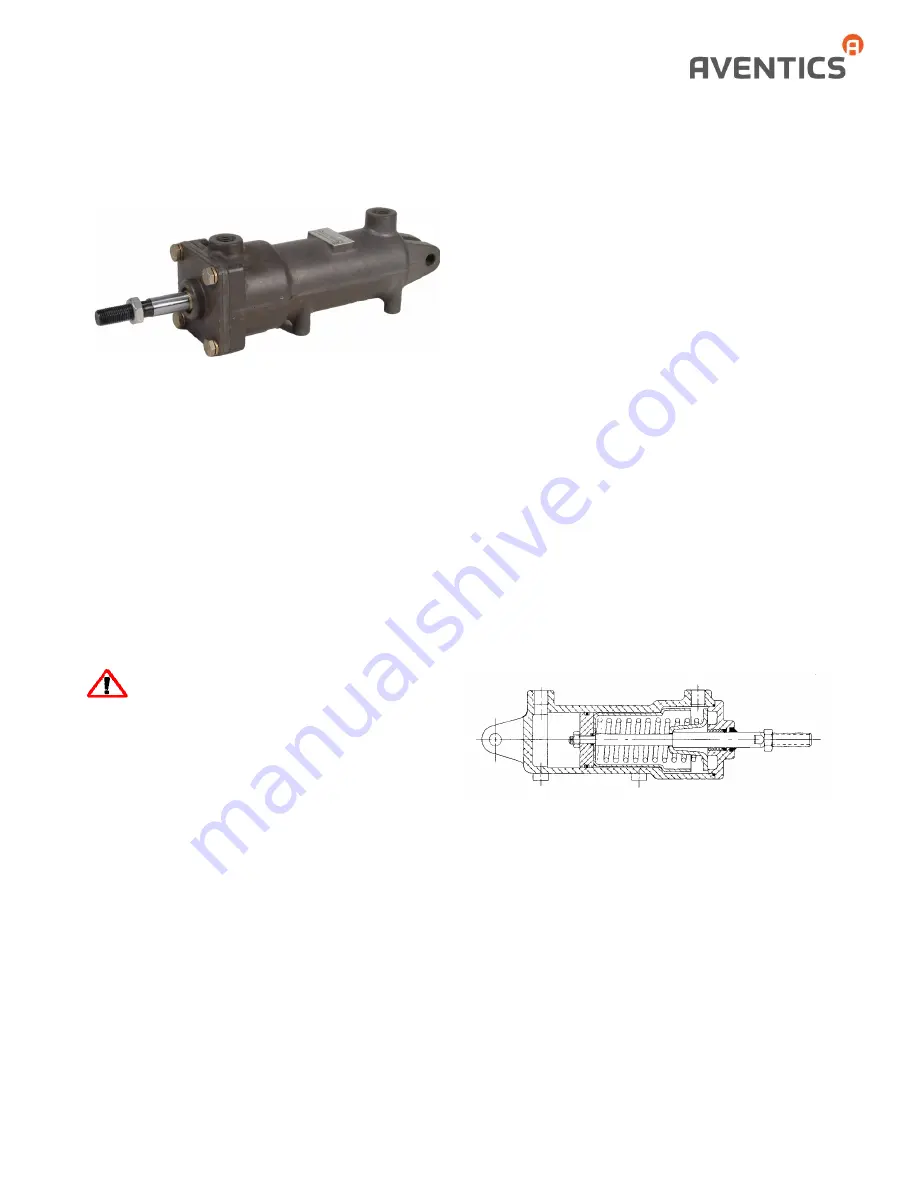

The three-position cylinder is a fixed position device when

controlled by a four-way, three-position, exhaust-centered,

control valve such as the “A” or “D”

PILOTAIR

®

VALVE.

The cylinder has a wide range of applications, being

particularly suited for shifting transmissions and positioning

hydraulic valves. It is corrosion-resistant and constructed of

lightweight, die-cast, anodized aluminum heads, pistons and

body.

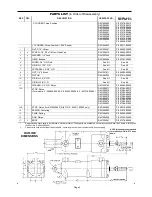

Maximum stroke of the piston rod is 1” (25.4 mm) on each

side of the center position, making a total piston rod travel of

2” (50.8 mm). External envelope dimensions of the cylinder

do not change, but shorter strokes are available in

increments of 1/16” (1.59 mm) for each position. The model

number of the cylinder and the model number of the piston

stop (13A) will have an identical four-digit suffix. The first

digit denotes the stroke in inches; the last three digits show

the stroke in thousandths of an inch.

WARNING: INSTALLATION

AND MOUNTING

The user of these devices must conform to all applicable

electrical, mechanical, piping and other codes in the

installation, operation or repair of these devices.

INSTALLATION!

Do not attempt to install, operate or repair

these devices without proper training in the technique of

working on pneumatic or hydraulic systems and devices,

unless under trained supervision.

Compressed air and hydraulic systems contain high levels of

stored energy. Do not attempt to connect, disconnect or

repair these products when a system is under pressure.

Always exhaust or drain the pressure from a system before

performing any service work. Failure to do so can result in

serious personal injury.

MOUNTING!

Devices should be mounted and positioned in

such a manner that they cannot be accidentally operated.

INSTALLATION & ADJUSTMENT

Because cylinders are installed at the end of an air system,

they are vulnerable to dirt and moisture carried through the

air lines. Therefore, before installing the three-position

cylinder, all air lines in the system should be blown clean. It is

recommended that the cylinder be mounted with the ports

facing down. Gravity can then assist in preventing foreign

material from accumulating in the cylinder by removing it

through the control valve exhaust.

In providing a mounting for the cylinder, an adjustable link

must be included between the piston rod and the lever to

which the rod is connected. The cylinder stroke should be

checked in its center position when aligned with the lever to

be operated. Check for exact register, making sure the clevis

pin is free from load in the center position.

This procedure will allow any inaccuracies in leverage ratio or

manufacturing tolerance to be absorbed at the extremes of

the stroke where exact registration is of least importance.

Also, any inaccuracies will be divided between the extreme

positions. When alignment is done at one of the extreme

positions, inaccuracies are all in the same direction.

OPERATION

Maximum operating pressure of the three-position cylinder is

150 psi (10.3 bar) at a temperature range of -40°F to 180°F

(-40°C to 82°C). The cylinder is held in its center position by

a coil spring caged on the piston rod. When air pressure is

supplied to the Cap-End Port, the piston rod moves to its

extended position. When pressure is supplied to the Head-

End Port, the piston rod moves to its retracted position.

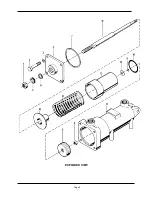

ASSEMBLY VIEW

MAINTENANCE

Periodically disassemble the cylinder for cleaning, inspection

and lubrication. Clean all metal parts with a nonflammable

solvent, and wash all rubber parts with soap and water.

Rinse thoroughly and blow dry with a low-pressure air jet.

Replace those parts which are damaged or worn.

Reassemble the cylinder, using the exploded and assembly

views as reference. No special tools are required. To avoid

cutting or nicking the piston “O” ring, carefully insert the

piston rod assembly into the cylinder bore with the piston

tilted at a slight angle. As the assembly proceeds, lubricate

all “O” rings with Dow Corning.

MULTIPOSITION AIR CYLINDER

CAST ALUMINUM

THREE-POSITION - SPRING-CENTERED

SERVICE INFORMATION

SM-1000.4916

Содержание R431004052

Страница 2: ...Page 2 EXPLODED VIEW ...