22

Kice Industries, Inc.

MAN-100-000-008

110722

Maintenance and Service Continued

9. Repeat steps 3 through 7 for the opposite endplate.

10. Prepare new rings of packing for installation.

a. If available, use a mandrel or shaft that matches the exact size of the rotor shaft.

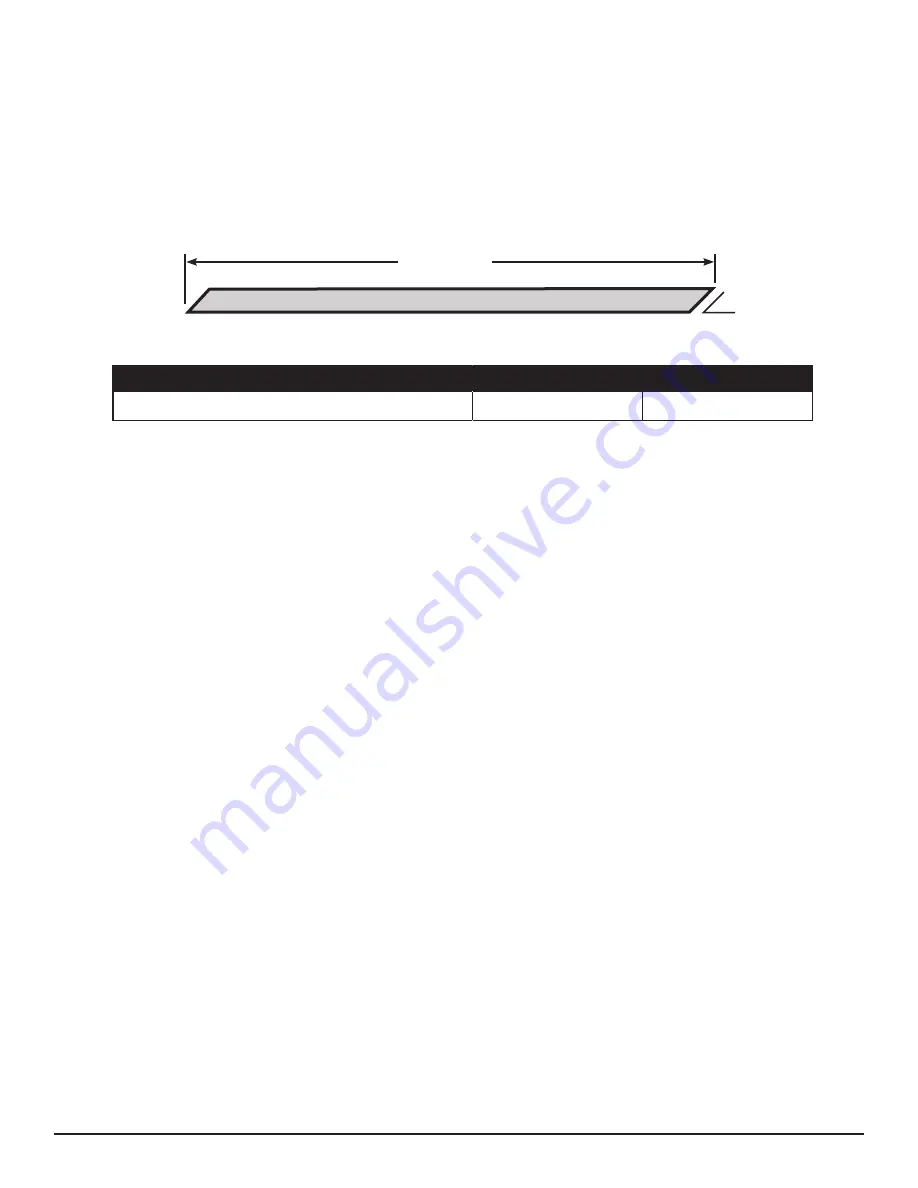

b. Cut packing rings at 45° angle.

c. Use a sharp knife. A dull knife will cause the packing to open up making sealing more difficult.

11. Wrap the first ring around the shaft and note the position of the joint (Figure 9).

12. Push the first ring into the packing gland using the packing retainer.

13. Slide packing retainer out of way to access packing gland pocket.

14. Wrap the second ring around the shaft and offset the joint 180° from the position of the first ring

(Figure 9). Push it into the packing gland using the packing retainer then slide packing retainer out

of packing gland pocket.

15. Wrap the third ring around the shaft and offset the joint 180° from the second ring (Figure 9).

Push it into the packing gland pocket using the packing retainer.

16. Evenly tighten the packing retainer bolts until light pressure is applied to packing.

17. Repeat steps 10 through 16 for the opposite endplate.

18. Reattach drive components and guards in the opposite order they were removed.

19. Restore power to airlock with no material passing through the airlock.

20. Equally tighten the bolts until the motor begins to labor.

21. Back off each retainer bolt 1/8 turn.

22. Repeat steps 20 and 21

after two hours of run time.

Airlock Size

Approx. Length

Kice Kit Part#

30"

11"

AIRLOCKPACKKIT4

Packing Length

45°