510 Keysight Technologies N9040B UXA Signal Analyzer Service Guide

Functional Tests

Displayed Average Noise Level (DANL)

13.

through

to fill in the remainder of

for

your analyzer frequency range.

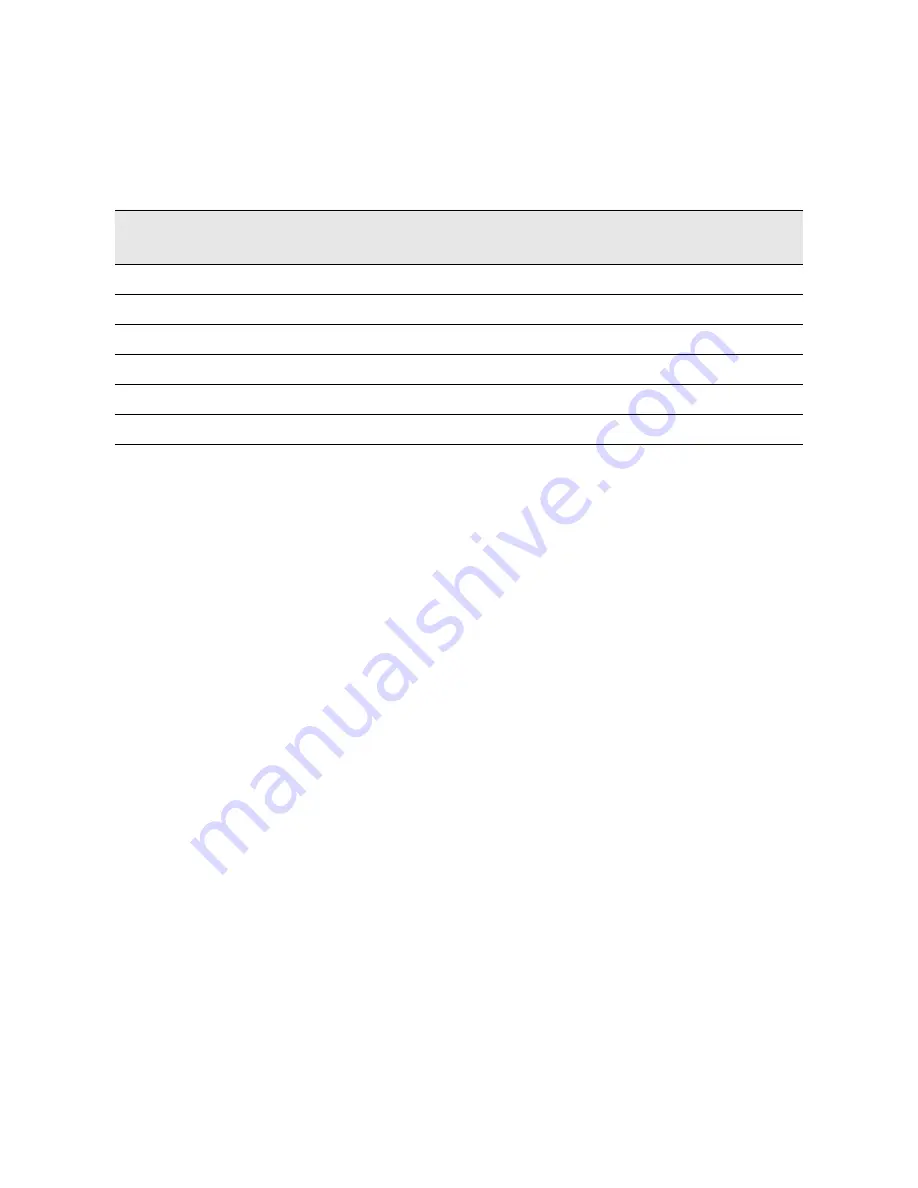

Table 17-1

Displayed Average Noise Level (DANL) Results

Center Frequency

Measured Average Noise Level

(dBm)

Normalized Average Noise

Level/(1 Hz BW) (dBm)

Test Limits

(dBm)

10 MHz

–153

2 GHz

–152

6 GHz

–148

13 GHz

–147

20 GHz

–140

26.5 GHz

–133

Содержание N9040B Option 513

Страница 4: ...4 ...

Страница 138: ...138 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Instrument Messages Condition Messages ...

Страница 240: ...240 Chapter 11 Hardware Options A21 Wideband Analog IF Troubleshooting Figure 11 1 Analog IF Block Diagram ...

Страница 256: ...256 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Block Diagrams Block Diagrams Block Diagrams ...

Страница 306: ...306 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Replaceable Parts Figure 14 2 External Hardware ...

Страница 338: ...338 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Replaceable Parts Figure 14 28 Chassis ...

Страница 346: ...346 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Replaceable Parts ...

Страница 502: ...502 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Post Repair Procedures ...

Страница 532: ...532 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Functional Tests Scale Fidelity ...

Страница 536: ...536 Keysight Technologies N9040B UXA Signal Analyzer Service Guide Instrument Software Software Updates ...

Страница 541: ...Index Index 541 Y yellow LED 48 51 yig filter see A12 YTF YTF see A12 YTF ...